Background

Control Room Annunciators are an integral part of a nuclear plant’s main control room that alert operations staff visually and audibly when an abnormal plant condition occurs. Annunciator systems in today’s operating fleet are often original plant equipment facing mechanical fatigue (aging), component obsolescence, and limited flexibility to incorporate modern approaches to plant operations.

Westinghouse offers an Ovation-based form, fit, function replacement annunciator system that can retain the spatial awareness and likeness of an existing system, minimizing impacts on operator training and alarm response procedures. A replacement annunciator system is offered with traditional lampboxes window faceplates or with large format computer displays that can reduce hardware I/O and offer an enhanced Operator interface. Operationally, the modern system can completely replicate the alarm management capabilities of an existing annunciator system with respect to alarm flashing/reflashing, acknowledgement, reset, and silence, and can be integrated with existing control board buttons. Alarm windows and lists are unified in the Ovation alarm viewer and can provide advanced capabilities such as alarm suppression, shelving, cutouts, and one-click access to alarm response procedures. Traditional, first-out, and permissive annunciator functionality is supported, as well as sequence-of-events recording. Audible annunciator indications can be provided though PC based workstations or by integration with an external alarm horn.

Description

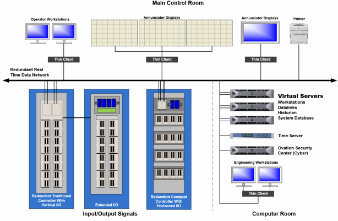

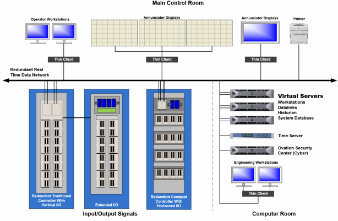

Example Standalone Annunciator System Architecture

Annunciator Replacement in Westinghouse SNUPPS Simulator

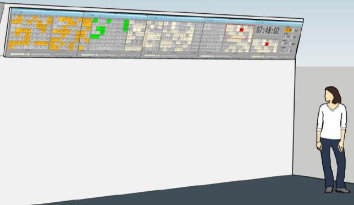

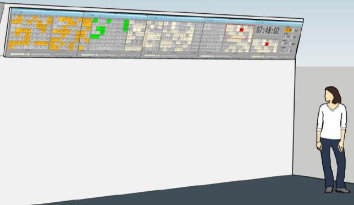

Annunciator Graphics for Integrated Display Wall

Integrated Display Wall

The Westinghouse annunciator system replaces an existing standalone annunciator system with an Ovation Distributed Control System (DCS) based solution. The system can be standalone or integrated with a new or existing Ovation control or information system. The Ovation DCS infrastructure is comprised of a software developer/engineering workstation, operator workstations, historian, and cyber security system, with Ovation controllers and I/O to acquire the annunciator inputs and interface to the control board alarm management buttons. Legacy annunciator lampboxes can be replaced with an updated faceplate (windows) driven by Ovation digital outputs, or alternatively, by a “display wall” that mimics the look of lampboxes on large format computer displays that eliminate the need for digital output hardware and wiring. Each tile is replicated to be the same size, font size, and color as the current system. Each lampbox window requires inputs to the annunciator system that are typically from a dedicated hardware input card. When integrated with a new or existing Ovation control system, hardware inputs can be reduced if the annunciator input is already processed by the existing Ovation system. As control and information systems are added in the future, duplicate I/O can be removed and the native control systems points can be used as annunciator inputs.

Ovation Control Builder logic is used to calculate the state of each annunciator window. With a software-based rather than hardware-based implementation, new points can be created and combined to develop the alarm signal and quickly evaluated and deployed.

The annunciator system supports replication of traditional annunciator windows, on/off status windows, and first-out annunciator windows. Alarm management can use the hard pushbutton interface, the graphical user interface displays, or the Ovation base alarm system to acknowledge, reset, and silence alarms.

Each lampbox is replicated via an Ovation display. Each display provides controls to silence and acknowledge the alarms on that display. The set of lampbox displays are continuously shown on the video display wall mounted on the top of the control board. If lampbox faceplates are used as an alternative to a display wall, graphic displays are still available within the system to be viewed on an Ovation operator workstation to allow soft alarm management and provide backup in the event of a failure of a dedicated display on the top of the control board.

Benefits

A Westinghouse Ovation-based annunciator solution provides the following specific benefits:

- Minimizes operator training and plant procedure modification by replicating the fit, form, and function of legacy annunciator systems.

- Integration of existing alarm response procedures.

- Reduces hardware footprint and increases standardization by sharing I/O and data acquisition hardware between new or existing Ovation plant systems. Non-Ovation annunciator systems would require duplicate I/O.

- Supports advanced alarm concepts like modal alarming, alarm grouping, and iconic alarming integrated with control graphics.

- Provides process-based alarm list filtering by priority, system, or alarm type.

- Integrates with Ovation Process Historian to provide electronic records of alarm history and sequence of events.

- Lowers cost of operations, maintenance spare parts, and training by building on a common platform with other Ovation systems.

- Future-proof foundation for plants planning for long term operations and transitioning to a modernized control room via systematic alarm reduction and soft annunciator replication that can be implemented with minimal hardware expense.

Experience

Installed at two units in the United States and the Westinghouse SNUPPS simulator, planned installations at six additional units.

Ovation is a registered trademark of Emerson Process Management