Advanced Optimization Services

Advanced Optimization Services Reduce Utility Costs and Improve Equipment Reliability

Around the globe, utilities need a better, smarter way to make informed decisions that minimize outages, lower costs, increase energy output and broaden profit margins.

Our team has expertise across a wide variety of disciplines to provide unique solutions through data analytics, software development and world-class engineering. Leveraging more than 135 years of practical innovation combined with the latest industry data and our network of global resources, our experts are focused on developing custom solutions for specific utility challenges across various plant designs.

Our Capabilities

Advanced Optimization Services combines our industry-wide data set, cutting-edge digital tools and analytics, and over 3,000 nuclear experienced engineers and analysts to deliver services focused on reducing costs while maintaining or improving equipment reliability. Advanced Optimization Services has a comprehensive portfolio of standard Services and Software Products that combine our digital and nuclear expertise:

Westinghouse OptiLife™ Service Center:

Our OptiLife™ Service Center uses the power of data and strategic insight to help utilities achieve continued, consistent delivery of nuclear energy to the communities they serve.

This strategic partnership optimizes plant equipment maintenance, procurement and inventory management, while leveraging Westinghouse centralized, digitalized engineering services that generate insights focused on reducing costs and improving overall reliability.

As a predictive planning tool, the OptiLife™ Service Center increases plant visibility, streamlines resource use and adds value by encouraging intelligent capital reallocation.

To deliver robust insights from our global data, the OptiLife™ Service Center aggregates information from nearly 200 international power plants, including PWR, BWR, VVER, CANDU® and AGR.

Westinghouse’s expert engineers leverage this data set, along with proprietary analytics and AI, to make predictions and suggestions in real time. This information is then visualized and used to generate actionable insights for application across the plant.

Services delivered through the Westinghouse OptiLife™ Service Center:

- Preventive Maintenance Optimization

- Predictive Maintenance

- Enhanced Work Management

- Enhanced Procurement Engineering

- Enhanced Inventory Management

Software Product Lines:

- Proactive Obsolescence Management System (POMS)

- Configuration Management Interface System (CMIS)

- Equipment Reliability Management System (ERMS)

- Enhanced Procurement Engineering

- Control Room Automation (CORA)

Advanced Optimization Services also supports custom solutions using our industry knowledge and data, advanced data analytics and nuclear expertise to help our customers solve their unique challenges.

Featured Solutions

Proactive Obsolescence Management System (POMS)

A one-stop shop for identification, prioritization, and resolution of station obsolescence, POMS provides quick and easy retrieval of equipment and vendor obsolescence information. Key benefits include early notice of obsolescence issues, improved decision-making capabilities, enhanced analysis of equipment bill of materials prioritization via a top list of obsolescence risks and the opportunity for industry collaboration. POMS allows utilities to integrate obsolescence information into site departments including System Engineering, Work Management, Supply Chain and Procurement Engineering. The POMS Suite consists of:

- POMS base product includes our Vendor Contacting Process that contacts over 20,000 Original Equipment Manufactures each year to provide our customers with Obsolescence Statuses for over 500,000 models including over 270,000 Potential Solutions

- Obsolescence Manager (OM) provides users with a risk-based prioritization with configurable algorithm

- Preventive Maintenance Forecaster, which provides users with a schedule-based prioritization including impact dates

- POMS Web-Service provides customers with the ability to integrate obsolescence data into their Enterprise Management Systems

POMS LOGIN

Configuration Management Interface System (CMIS)

Westinghouse’s CMIS software suite is an industry-proven tool to implement the Engineering Standard Design Process (SDP) per industry procedure IP-ENG-001. This tool supports the nuclear industry by providing a robust, up-to-date software tool for the preparation, review and completion of Engineering Changes. CMIS helps customers to automate the process while enforcing procedural requirements and includes single sign-on, electronic signatures, review workflows and package generation.

Equipment Reliability Management System (ERMS)

ERMS is a suite of tools focused on the implementation and optimization of INPO AP-913 with the goal of improving efficiencies and overall equipment reliability. ERMS consists of the following:

- Risk Classification Management (RCM) – Enterprise-wide risk management tool allowing for prioritization and visualization of risks impacting the plant, processes or people from inception through mitigation and elimination.

- Equipment Reliability Workbench (ERW) – Software tool that facilitates the implementation and optimization of INPO AP-913 including classification, maintenance templates, maintenance strategies and asset management plans.

- Plant Health Monitor (PHM) – Software tool focused on the automation, development and review of System Health Reports needed to fulfill the Nuclear Regulatory Commission requirements. Plant-level and system-level scores and ratings are automated, allowing engineers to identify top risks and capture improvement plans.

- Maintenance Rule – Software tool that reduces the time needed to fulfill the Nuclear Regulatory Commission requirement 10CFR 50.65, known more commonly as “Maintenance Rule.” The time savings comes in the form of a reduction in man-hours for the System Engineers as well as the Maintenance Rule Coordinators by providing one system for storing, retrieving, and viewing Maintenance Rule information related to Structures, Systems, and Components (SSCs).

Control Room Automation (CORA)

Westinghouse’s CORA suite is focused on the automation of Operator Logs and Operator Rounds and consists of two main products with AutoLog and AutoTour:

AutoLog is a scalable, automated solution that meets the needs of the nuclear industry in maintaining logs for safety and environmental compliance.

- Eliminates the costly, error-prone step of interpreting handwritten data.

- Improves safety awareness across operations by enabling the viewing of log data from any computer.

- Delivers a precise view of current plant status.

- Provides central location where all equipment reliability items come together.

AutoTour is a platform that reduces the time and effort involved in gathering field data and supports equipment health management on high-value assets.

- Interfaces with existing work management system.

- Reduces the effort and cost of data collection while increasing data quality.

- Improves safety in sensitive plant areas such as the control room.

- Allows pictures, video and sound data to be recorded on equipment in the field.

- Guides users through specific steps to complete equipment testing rounds.

- Optional barcode scanning reduces the risk of taking readings at the wrong location.

Balance of Plant Engineering

Westinghouse’s engineering and project management teams are highly skilled at executing projects from the critical initial planning and scoping phase, through detailed engineering, installation, and startup. Our team is comprised of more than 1,200 engineering resources worldwide covering over 200 specialty disciplines to provide the most appropriate, cost-effective, and comprehensive solutions to our customers.

Whether your project is large or small, Westinghouse works collaboratively to ensure the deliverable meets both the customer and industry’s stringent requirements. Our team leverages significant field execution experience to provide additional technical support and consulting as required. With extensive experience in CANDU®, PWR and BWR technologies, we’ve solved technical, licensing, and plant operational challenges for nuclear plants for over 50 years.

Design Engineering

Leveraging the combined support and expertise from our global team of experts, we integrate proven practices and standards in our collaborative approach to deliver customized design packages.

Comprised of more than 5,000 engineers, technicians and tradespeople, our specialists have extensive global knowledge in CANDU® technology, PWRs, BWRs and a wide range of experience in fuel handling, waste packaging and processing systems. From concept to implementation, your unique specifications and requirements will be front-and-center as we tailor a solution that best fits your needs.

We offer design engineering services in a variety of disciplines:

- Civil

- Electrical

- Human Factors

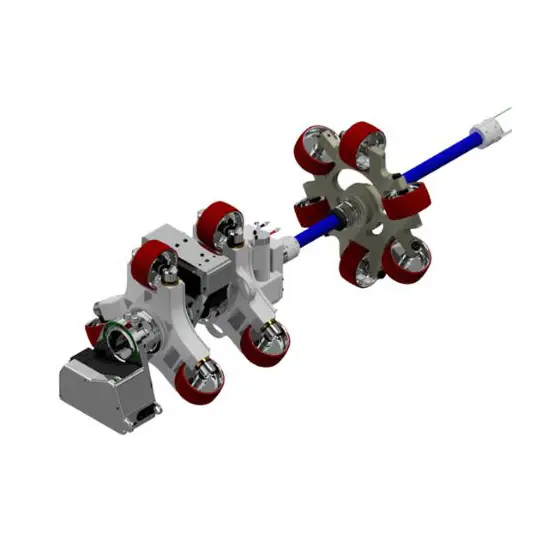

- Mechatronics & Robotics

- Mechanical

- Software

- Structural

- Instrumentation and Control (I&C)

Our Design Engineering portfolio includes:

Integrated Solutions

Our robust design engineering capabilities enable us to deliver turnkey engineered solutions that are customized to your needs. From plant engineering to first-of-a-kind inspection and maintenance tooling, our diverse teams possess the critical skills required for a successful project, every time.

Consulting Services

We provide comprehensive Owners Engineer and advisory services, operating as an extension of client organizations and providing necessary tools to develop and manage projects from technical review to regulatory interfacing.

Centre of Site

Our multi-disciplinary team has extensive experience providing infrastructure and construction engineering services to support facilities and buildings in nuclear power stations.

Facilities Engineering

For over 20 years, Westinghouse has provided a variety of engineering services to site owners, managers and developers. Our LEED-certified teams have in-depth experience in the areas of Civil, Structural, Mechanical and Electrical Engineering. We offer all aspects of consulting engineering services required for the design of new buildings and the expertise to design and develop structural additions, modifications and renovations. We offer a complete suite of mechanical consulting services for the design of all building mechanical systems such as heating, cooling, ventilation, instrumentation and plumbing. We provide a comprehensive offering of electrical engineering design and consulting services including powder distribution systems, building automation systems, standby emergency systems, energy conservation and daylight harvesting systems.

Todays building envelope systems are comprised of a complex mix of high-performance materials which need to be properly specified and installed to perform as intended for the life of the building. Westinghouse understands the characteristics of building components and can provide clients with all available options towards maintaining, upgrading or replacing them.

Westinghouse utilizes state of the art modeling and rendering software to produce virtual models of our designs. Three-dimensional modeling brings concepts to life allowing the fit, form and function to be observed in virtual and physical space. This process enables the identification of potential design and construction discrepancies early in the conceptual process. We are experts in multi-discipline BIM technology which allows us to produce complex designs, investigate multiple solutions and take advantage of the most current analysis software to reduce waste and increase efficiency. Our 3D modeling and rapid prototyping machine allows us to convert our 3D virtual models to scaled, 3D physical models. The final product is a durable, functional model with accurate, fine feature details.

Fire Protection

With over 30 years of industry experience, you can build confidence in your fire defense systems with our comprehensive fire protection portfolio.

From design to implementation to routine examinations, our team of world-class experts delivers performance-based solutions through innovative technologies and proven local and global experience.

Supporting both detection and suppression programs, our experts are factory-trained in fire alarm systems, programming and hardware. Leveraging our robust licensing experience with a fully collaborative approach, we provide customized, cost-effective fire protection solutions to keep your site and personnel safe.

Our team members are heavily involved in Canadian and international fire protection committees and organizations including UL/ULC, NFPA, SFPE, NBC, and CSA N293 / N393. This ensures we remain aligned with the most recent operational experiences from various industries that are then incorporated into future designs and assessments.

Capabilities

Programs

- Detection: Our team determines performance requirements, develops detailed design documentation and assesses optimal installation processes for client specific needs.

- Suppression: Our team evaluates system performance and water and clean agent supply requirements specific to Canadian or international codes and standards depending on applicable jurisdiction.

Design Services

- Fire Alarm Systems

- Suppression Systems

Evaluation and Inspection

- Reviews and Assessments

- Retrofit Planning and Management

Fuel Handling

Westinghouse supports CANDU® customers with cost-effective solutions to fuel handling component obsolescence challenges. Our experts provide a wide range of services which allow customers to upgrade their existing components with new and readily available technology while ensuring seamless integration into the system – whether reverse engineered or new components. Drawing upon Westinghouse’s extensive experience, our team provides these services in mechanical, electrical and instrumentation & controls scopes.

Capabilities:

- Reverse engineering of existing components

- Updating technology and available hardware

- Redesign components from tech spec to intended functionality

Experience:

- Compressor replacement conceptual engineering

- Ram ball satellite removal

- Power supply redesign and components

Instrumentation & Controls

Westinghouse provides obsolescence engineering for a wide range of components which support reactor controls and fueling machine controls within a CANDU® reactor. From redesigning boards used in the control system to creating entirely new systems, Westinghouse is committed to providing customers with support throughout the lifecycle of the control and safety systems of their plants.

We support CANDU® maintenance for critical tooling when obsolescence challenges arise as a result of aging control systems. Due to expensive maintenance activities and hard to get replacement components, Westinghouse regularly engages with customers to develop new control systems that utilize the latest technology. This maintains a plug and play approach for new components, allowing the tooling system to be used in the same manner it was previously without any change to the operator’s experience.

Capabilities:

- In-kind control system replacement

- Individual component replacement

- Reverse engineering and redesign

- Repair and replacement