Background

To help utilities maintain Class 1E qualification standards when replacing Westinghouse medium-voltage motors, Westinghouse rotating equipment services (RES) offers interchangeable medium-voltage motors in the World Series, Lifeline D, Lifeline A and Type CSP designs for safety-related Class 1E applications.

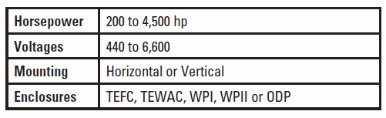

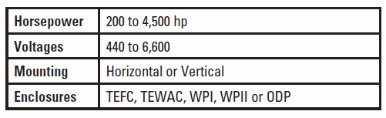

These medium-voltage motors (200 to 4,500 hp) are built to Westinghouse original design specifications with horizontal or vertical mounting, and are available in a range of NEMA enclosures. The motors utilize the Westinghouse environmentally qualified Class B or F form-wound Thermalastic Epoxy insulation system.

Lifeline D, Lifeline A and Type CSP duplicate motor designs are certified to be electrically and mechanically interchangeable in form, fit, function and seismic and environmental qualification with the original motor. The World Series updated replacement design motor is also certified to be electrically and mechanically interchangeable in fit and function as well as environmentally qualified, consistent with the original motor. The motor also can be seismically qualified, upon request.

New safety-related medium-voltage motor

Description

Westinghouse medium-voltage motors are designed for high efficiency: they utilize copper/copper-alloy rotors, induction brazing, swaging and through-bolt construction. All of the medium-voltage motors are squirrel-cage induction-type, and feature the environmentally qualified and reliable Westinghouse Class B or F form-wound Thermalastic Epoxy insulation.

Utilities have a number of options to choose from:

Performance Options

Interchangeability

Utilities can maintain qualification standards by replacing existing motors with ones that are certified to be electrically and mechanically interchangeable with the original equipment. When replacing Westinghouse motors, our certification is based on our review of the design records for the original motors. To replace non-Westinghouse motors, we base our certification on our review of information supplied by the customer. Although there could be minor changes in motor weight, RES will certify that the new motor’s environmental and seismic qualification is equal to or exceeds that of the original motor.

Qualification

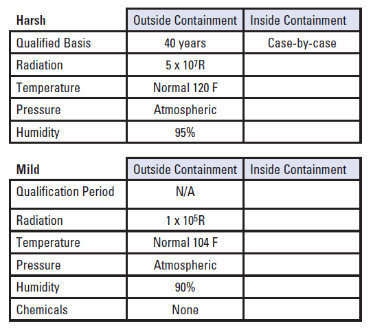

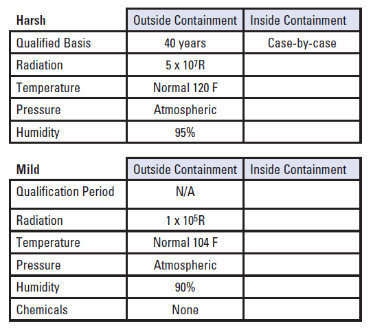

Our Class 1E medium-voltage motors can operate in both harsh and mild environments. Westinghouse Class 1E medium-voltage motors, components and parts meet the applicable requirements of the U.S. Nuclear Regulatory Commission (NRC) for quality control and quality assurance, including the requirements issued in 10CFR50, Appendix B. Westinghouse RES also complies with 10CFR21 reporting requirements.

For safety-related Class 1E applications, the medium-voltage motors are further qualified to the accepted environmental and seismic standards.

Seismic Qualification

Seismic qualification is accomplished using a standard static or a static coefficient analysis. If Westinghouse performed the original analysis, the resultant seismic requirements will be met or exceeded, and the original report will remain applicable if a duplicate motor is purchased. For updated replacement motor designs, for those motors that originally did not have a seismic analysis performed, or for those that have new seismic requirements, we can provide seismic qualification as an option.

Environmental Qualification

RES-supplied medium-voltage motors are qualified to the following typical environmental parameters:

Medium-voltage motors can be qualified for out-of-containment, high-energy line-break environments on a case-by-case basis. Lifeline A and Type CSP motors for in-containment (reactor containment fan cooler and safety injection recirculation pump) applications are qualified to IEEE Std 323-1971 and IEEE Std 344- 1975.