Background

At Westinghouse, pump and motor service is one of our primary specialties. For over 35 years, we’ve designed and manufactured pumps and motors for the nuclear industry. As this equipment ages, it must be maintained, repaired, or sometimes replaced.

We have the capabilities to complete pump and motor field, shop, and engineering services work skillfully and in the shortest possible time without sacrificing quality, safety, or procedural compliance. We also offer replacement motors and parts that are supplied with the original Westinghouse qualification.

Description

NCRC

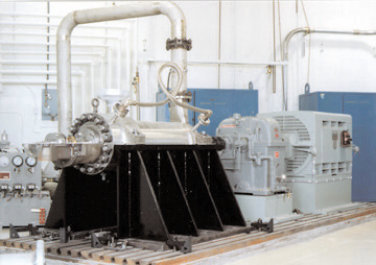

With the completion of our new state-of-the-art Nuclear Component Repair Center (NCRC) in Madison, Pennsylvania, the nuclear industry now has access to the most comprehensive, experienced, quality, and safety-conscious source for engineering and service of pumps, motors, and components. Housing our engineering and shop services and serving as home base for our field service teams, this licensed facility is approved to receive radioactive contaminated equipment from any utility. And we’re always open to customer visits.

This organization is staffed with more than 40 highly experienced people, including almost 30 engineers dedicated solely to pump and motor engineering and services (auxiliary pumps and motors through reactor coolant pumps [RCPs] and motors).

Our field services personnel are part of this organization and when they are not directly engaged in field engineering activities, they’re working in shop and on engineering projects. When they’re working at sites, they’re supported by the Service Center.

In addition to the U.S.-based support structure, Westinghouse has expanded its pump and motor capabilities to support our European customers.

Benefits

As a one-stop shop facility, we offer complete pump and motor field, shop, and engineering services performed costand time-effectively without sacrificing quality, safety, or procedural compliance. We also offer direct and immediate access to original equipment engineering and parts.

Description of Services

- RCP Field Services (U.S./Europe)

- Outage planning

- Turnkey services

- Seal inspection and changeout

- Field installation of components and upgrades

- Equipment and Component Engineering

- Design responsibility/control

- Product enhancements

- Project management of major hardware replacements

- Engineering consultation with operating plants

- Component aging issues management

- Regulatory issues

- Component uprate analysis

- Shop Services (U.S.)

- Contaminated pump and motor repair

- Contaminated pump test loop

- Component rebuilds (pumps, motors, seals)

- Shop Services (Europe)

- Contaminated pump and motor repair

- Component rebuilds (pumps, motors, seals)

- Chemical Decontamination

Using the qualified NITROX and NITROX-E processes, reactor components can be chemically decontaminated to allow subsequent component maintenance work to continue with minimal radiation exposure to pump repair personnel.

The NITROX-E process consists of the cyclical application of oxidizing and reducing chemistries to effect dissolution of the deposited and grown-on oxide film that contains the entrapped radionuclides that cause elevated dose rates on reactor components. The NITROX-E process has been demonstrated to be effective at dissolving most stainless steel oxide films, and is particularly well suited for the decontamination of stainless steels exposed to oxidizing chemistry conditions.

- New Replacement Motors/Parts and Engineering Studies

- Qualification maintained

- Duplicate motors

Alliances

To support our one-stop pump and motor shop capabilities, we’ve partnered with: Flowserve, Curtiss-Wright (EMD), and TECO-Westinghouse.

Human Performance

Westinghouse conducts lessons learned for each refurbishment project and applies this knowledge to future projects. The Corrective Action Program (CAP) is used to identify and address issues related to quality and performance.

Performance Observation Program (POP)

Westinghouse Field Services has implemented POP to identify and correct personnel behaviors considered to be “at risk” and to eliminate the underlying causes for these behaviors.

The observation program encompasses three critical areas: safety, quality of job performance, and customer service. Foundation principles for this initiative were established in Westinghouse personalized customer service programs, INPO human performance training, and a more recent focus on behavioral safety.

Human Performance Laboratory

The human performance observation awareness laboratory creates a highly interactive learning environment in which we can openly ask questions to improve our performance.

Always concerned about performance and safety of personnel, the lab is the next step in our journey to improve safety, human performance, and the quality of services to our customers.

Safety

Westinghouse is committed to achieving and maintaining world-class safety performance on a global basis while at all times maintaining compliance with country statutory regulations. Safety is a corporate core value and regulatory compliance is given top business priority. Accountability systems are in effect and leaders are supported and trained to do their work. Westinghouse conducts extensive safety training for all employees and world-class procedures and practices are developed and utilized.

Experience

Experience is an essential ingredient for successful outage performance. At Westinghouse we’re proud of our extensive experience and expertise in providing our widespread resources to aid in all phases of pump and motor work. We offer our capabilities to complete the pump and motor field, shop, and engineering services work skillfully and in the shortest possible time.

Westinghouse has successfully performed over 350 RCP and motor field services, including pump and motor replacements; RCP full-scope services; RCP advisory services; RCP motor and advisory services; pump pull; and other RCP and motor-related services. In addition, we have successfully performed over 150 primary RCP and motor shop services.

Summary

Westinghouse is uniquely qualified to provide both full-scope and technical advisory services for all facets of pump and motor field maintenance and repair activities. Westinghouse brings over 55 years of quality service, technological expertise, and field-tested and experienced personnel to each of the variety of jobs we perform each year.

Our RCP Project Managers have an average 12 years of nuclear pump and motor experience. Our full-time RCP personnel have a cumulative 197 man-years of RCP seal and motor experience, which is significantly increased when factoring in our trained and qualified core staff augmentation personnel.

Benefits

As a one-stop shop facility, we offer complete pump and motor field, shop, and engineering services performed costand time-effectively without sacrificing quality, safety, or procedural compliance. We also offer direct and immediate access to original equipment engineering and parts.