Background

Westinghouse’s Nuclear Component Repair Center (NCRC) in Madison, Pennsylvania (USA), provides the nuclear industry access to the most experienced quality and safety-conscious resources for pump, motor and component engineering and repair services. The NCRC has a large and well-equipped repair machine shop for working on contaminated equipment and supporting a full scope of services.

An in-house engineering group, experienced machinists, repair specialists, and mechanical and electrical inspectors certified to American National Standards Institute standards support all repair/refurbishment services. Services provided meet 10CFR50 Appendix B and ISO 9001 quality standards.

Description

The NCRC is a fully equipped 8,000 square-foot facility, providing a complete range of services for contaminated and safety-related motors of both Westinghouse and non-Westinghouse designs. With a 10CFR50 Appendix B program, ISO 9001 certification and the Nuclear Procurement Issues Committee approval, Westinghouse fully understands the design responsibility and service reliability required by safety-related and critical service nuclear components.

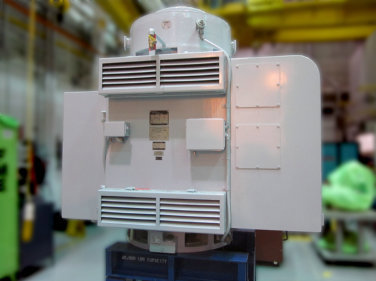

Dyno testing of a 2,000-hp motor

Auxiliary Motor Service Capabilities

- Maintenance/repair of motors from all manufacturers including Westinghouse, Reliance, Siemens-Allis, Allis-Chalmers, Electric Machinery and General Electric (Alliance Agreement), from fractional horsepower up to 13,000 horsepower used in both pressurized water reactor and boiling water reactor nuclear plants

- Safety-related, seismically and environmentally qualified refurbishments and rewinds

- Contaminated and non-contaminated services

- Typical safety-related auxiliary motors repaired at the NCRC include:

- Safety injection (SI)

- Residual heat removal (RHR)

- Essential service water (ESW)

- Containment spray (CS)

- Containment fan (CF)

- Component cooling (CC)

- Auxiliary feed water (AFW)

- Other motors which are serviced through the NCRC are:

- Reactor recirculating pump

- Heater drain pump

- Hotwell pump

- Control rod drive

- Emergency diesel generator (EDG) fuel oil transfer pump

- Compressor

- Original equipment manufacturer (OEM) parts and drawings

- Reverse engineering using computer measuring machine, laser scanning and X-ray fluorescence material analysis

- Stator rewinds with qualified insulation systems (Westinghouse/Reliance/Howden North America Inc.)

- Vibration data acquisition and analysis using IOtech, Computational Systems, Inc., and automated diagnostics for rotating equipment

- Infrared thermography

- Dynamic balancing through 44,000 pounds

- Load testing through 2,815 horsepower horizontal/1,350 horsepower vertical

- No-load testing through 13,800 VAC

- Virtual witness of motor testing from customer’s home or office

Standard Scope of Service

When an auxiliary motor is serviced at the NCRC, the following standard work scope is performed:

- Receipt Inspection

- Visual inspection

- Stator electrical testing (insulation resistance, polarization index (PI), and winding resistance measurements)

- Auxiliary instrument testing

- Mechanical tests (air gap, endplay, shaft-extension total indicated runouts [TIRs], etc.)

- No-load testing (upon request)

- Motor disassembly

- Hot water cleaning/decontamination of components

- Oven drying of motor and stator

- Rotor total indicated runouts

- Visual and electrical inspection of stator

- Bearing inspection and replacement

- Main leads replacement (as required)

- Stator rewind (as required)

- Motor reassembly

- No-load test run

Benefits

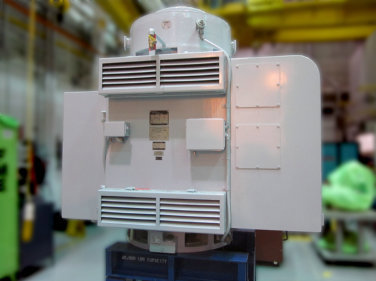

600-hp auxiliary motor

In addition to quality of execution and state-of-the-art processes, Westinghouse provides additional value by assigning a project manager to be the single point of contact with the customer. The project manager functions as the direct interface for all technical and commercial issues for every repair project.

Experience

Westinghouse’s extensive refurbishment expertise is also used on non-Westinghouse pumps and motors. Westinghouse has accumulated decades of motor design and qualification experience and is strategically aligned with partners that provide access to motor design and upgrade expertise of other OEMs such as General Electric, TECO/Westinghouse Motor Company, Reliance Electric and Howden North America Inc. Using human performance tools along with the ingrained practice of the Institute of Nuclear Power Operations principles for a strong nuclear safety culture in the work control processes, Westinghouse provides value added that supports life-cycle management while minimizing the risk of forced outages.