The Westinghouse Solution

As a full-service integrated valve and actuator maintenance company, Westinghouse performs preventative and predictive maintenance services and diagnostic testing on valves and actuators of all manufacturing types. We leverage our industry-recognized training programs, integrated project management approach and our First-Time Quality process to ensure that our customers’ most complex valve projects are completed on time and on schedule.

Customer Benefits

Westinghouse differentiates itself from our competition with a leadership team comprised of utility line managers with extensive maintenance and operations experience in the commercial nuclear industry that undergo a rigorous leadership training process. This direct “hands-on” utility experience is essential to the planning, execution, and on time delivery of complex projects.

We have an INPO modeled performance-based technical training and qualification program with EPRI AP-3 compliance certification. This approach improves quality while reducing cost to the utility by mitigating on-site qualification activities. Duty-area cross-qualification exists to enable technicians to support both actuator as well as in-body valve repairs; thereby reducing overall resource requirements and outage costs.

Westinghouse provides an integrated planning and project management system to safely execute any valve project on schedule and budget. Our integrated process includes in-depth pre-planning, comprehensive project reviews, risk assessments and contingency development.

We possess one of the industry’s top recruiting organizations comprised of twenty full-time recruiters staffing greater than 8,000 professional and craft positions during peak outage seasons.

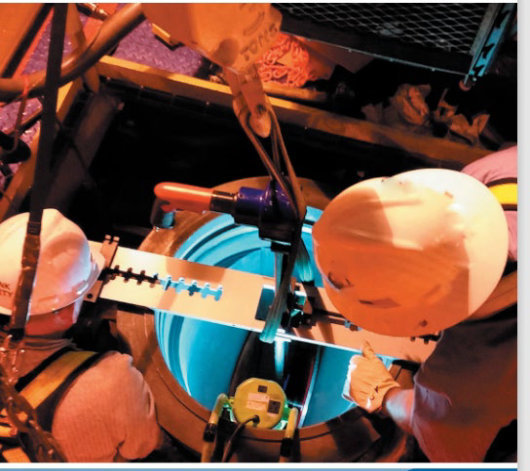

Mechanical Valve Capabilities

Corrective and preventive maintenance on all types of gate, globe, check, ¼ turn, pressure relief valves including:

- Bonnet and flange refacing & restoration

- In-place seat removal and replacement or restoration

- In-body and pressure boundary weld repair IAW ASME Section XI

- Wedge replacements, weld repair, and machining fit up

- Automatic welding capabilities

- Mobile machining centers with full turning, milling and repair capabilities.

- Small and large bore valve weld replacement

- Leak management and repacking program support and development

Air Operated Valve Capabilities

Service on all brands of air operated control valves, their actuators, and accessories including:

- Refurbishment of actuators and valves

- Bench setting and calibration

- Repair and replacement of accessories

- Integrated I&C maintenance providing complete managed task

- Diagnostic testing using all major testing platforms including VOTES Infinity®, QuikLook®, and Flowscanner®

Motor Operated Valve Capabilities

Extensive experience in all phases of Limitorque® and Rotorque® motor operator including:

- All phases of preventive and corrective maintenance of motor operator

- Setting of limit and torque switches

- Associated electrical maintenance to MCC’s and associated breakers

- Diagnostic testing using all major testing platforms including VOTES Infinity®, QuikLook®, and Flowscanner®

- Bench Test for actuator torque measurement.

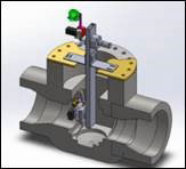

Main Steam Isolation Valve Capabilities

Westinghouse offers full turnkey MSIV services including:

- In-body machining with one time machine set up

- 3 axis computer mapping of internal surfaces

- Proven GTAW automatic welding

- Seat weld repair, machining and lapping

- Guide rib weld build up and single point oscillation machining

- 8x camera magnification

Welding Capabilities

Westinghouse’s specialty welding can support all facets of valve repair giving a depth of capabilities not found in other valve maintenance companies including:

- 540 welders qualified to the program

- In-house testing, training and qualification

- PQR, WPS, WPQ, per ASME Section IX

- 10 CFR 50, Appendix B and ASME NQA-1 compliant quality program

- Code Certificates of Authorization “S”, “U”, and “R”

VOTES Infinity®, QuikLook®, Flowscanner®, Limitorque® and Rotorque® are all trademarks of their respective holders