Background

In June 2020, the Nuclear Regulatory Commission (NRC) finalized Regulatory Guide (RG) 1.2361 for plants evaluating the rod ejection accident (or reactivity-initiated accident [RIA]). The regulatory change is an enhancement of the precursor (RG 1.772) requiring a more detailed transient analysis that cannot be completed in the old one-dimensional (1D) kinetics analysis methodology.

Westinghouse Solution

Westinghouse developed a three-dimensional (3D) coupled kinetics analysis documented in WCAP-15806-P-A3. The NRC-approved methodology is based on and automated code linking of the neutronics code SPNOVA (or ANC9) with thermal-hydraulic code VIPRE-W. The Westinghouse methodology uses the ANCKVIPRE code to automate the linking and then driving the enthalpy and Departure from Nucleate Boiling Ratio (DNBR) calculations.

The 3D methodology allows plants to more realistically simulate multiple core transients to comply with the NRC RG. Westinghouse has the expertise needed to perform these analyses for our customers. For utilities who self-perform, Westinghouse leverages our expertise to provide training and technology licensing.

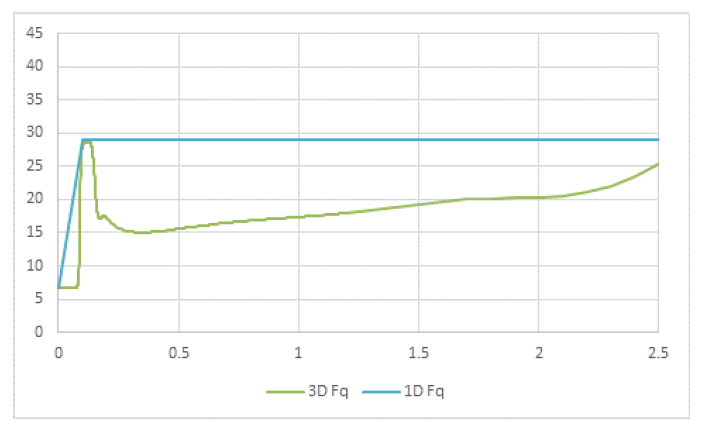

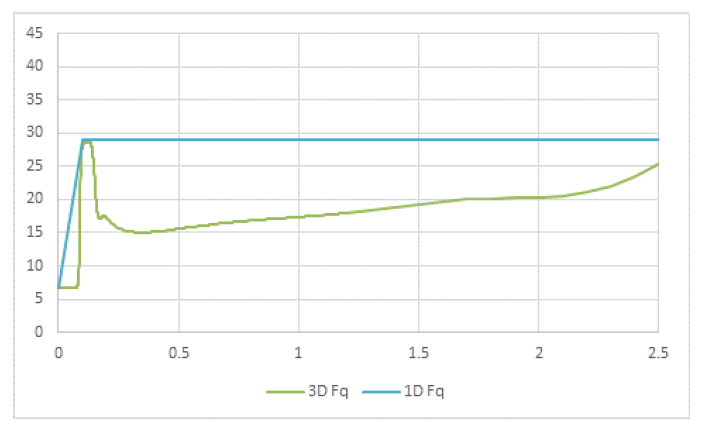

Comparison of the transient peaking factor versus time used in the 1D methodology and as calculated in the 3D methodology

Figure 1: Transient Peaking Factor Versus Time

Benefits

Flexibility

Allows for a variety of DNBR correlations, fuel performance models and plant operating strategies

Forward Thinking

Designed to analyze cores with mixed fuel vendors

Proven Experience

Provides a more realistic simulation of the core transient response while still allowing for application of all conservatisms required by the licensed methodology.

Figure 1 shows that more accurate modeling of Doppler feedback in the 3D methodology results in a reduction in the local power peaking after the nuclear power pulse, which in turn yields a lower peak fuel temperature for the transient.

Description

For a plant’s safety analysis of record (AOR), multiple core transient simulations are performed to determine the limiting combination of initial core conditions for each RIA criterion, in order to demonstrate compliance with RG 1.236.

Based on the margins calculated from the AOR, cycle-specific reload evaluations can be performed using cycle-specific kinetic simulations, simple static simulations similar to today’s reload methods, or a combination of the two approaches. Both the AOR and the reload analysis methods are flexible to address the RG 1.236 criteria without imposing restrictions on the core design or plant operations.

Table 1 shows a comparison of the clad failure and core coolability criteria from RG 1.77 and RG 1.236, which highlights the major changes in the RIA criteria, forcing plants to move to 3D methodology to stay compliant with the new NRC regulation.

| Category |

Criterion |

RG 1.77 |

RG 1.236 |

| Fuel Clad Failure / Clad Temperature |

Peak Fuel Enthalpy |

280 cal/g (WEC assumes 200) |

Burnup dependent, starting at 170 cal/g decreasing to 100 cal/g based on rod internal pressure |

| DNB |

Assumed failure if DNBR safety limit exceeded (WCAP-7588 assumed an explicit PCT limit of 2700°F) |

Assumed failure if DNBR safety limit exceeded for non-prompt critical cases only |

| Fuel Clad Failure (PCMI) |

Fuel Enthalpy Rise |

Not Applicable |

Burnup dependent, starting at 150 cal/g decreasing to 80 cal/g based on clad excess hydrogen |

| Molten Fuel Failure |

Fuel Temperature / Melting |

Not explicitly stated |

Assume clad failure if any part of the pellet melts |

| Core Coolability |

Peak Fuel Enthalpy |

Same as fuel failure limit |

230 cal/g |

| Fuel Temperature / Melting |

Not explicitly stated; (WCAP-7588 assumed melt limited to innermost 10% of pellet) |

Limited to innermost 10% of pellet |

| RCS Pressure Transient |

ASME Boiler & Pressure Vessel Code Section III, Service Level C |

Same |

Table 1: Comparison of RIA Criteria

Applicability

The 3D rod ejection methodology applies to new plant builds and current operating plants with the intention of submitting a license amendment request (LAR). The LAR is required for a change to the licensing basis such as an uprate, a fuel product change, or a change in operating strategy.

Experience

Westinghouse has global experience in implementing the 3DRE methodology analyses in multiple countries. The methodology has been applied to Westinghouse and mixed vendor fueled cores.

Westinghouse has demonstrated experience and technically advanced methods to minimize the impact to utilities adhering to the new regulatory guidance.

References

- RG 1.236- “Pressurized-Water Reactor Control Rod Ejection and Boiling-Water Reactor Control Rod Drop Accidents”, June 2020.

- RG 1.77 – “Pressurized-Water Reactor Control Rod Ejection and Boiling-Water Reactor Control Rod Drop Accidents”, May 1974

- WCAP-15806-P-A,” Westinghouse Control Rod Ejection Accident Analysis Methodology Using Multi-Dimensional Kinetics”, December 2003.

ANC is a trademark or registered trademark of Westinghouse Electric Company LLC, its affiliates and/or its subsidiaries in the United States of America and may be registered in other countries throughout the world. All rights reserved. Unauthorized use is strictly prohibited. Other names may be trademarks of their respective owners