Background

In response to industry motivation to reduce the cost and effort associated with reload low power physics testing (LPPT) – particularly elimination of rod worth measurements – Westinghouse has developed a methodology to optimize post- refueling startup physics testing. Our Alternate Rod Worth Verification (ARWV) approach validates the rod worth design predictions for each reload cycle.

Instead of performing explicit measurements on outage critical path, which necessitates several secondary tasks and administrative controls, the ARWV method validates control rod worth based on statistical analysis and plant observations inherent to typical refueling outage activities.

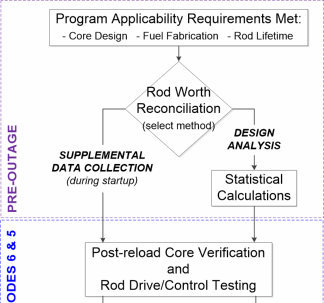

To ensure all licensing requirements are met, the ARWV project scope includes a comprehensive review of the entire unit-specific startup test bases from core loading through full power operation. The final deliverable is a redefined, robust core design validation program without the need for direct rod worth measurements.

ARWV provides complete and flexible core design validation

ARWV provides various paths for eliminating rod worth measurement based on our extensive plant startup testing and advanced methods. The approach for any given reload cycle startup can be tailored to plant owner preference, their use of/access to Westinghouse codes and methods, cycle-specific design changes, and the plant licensing basis.

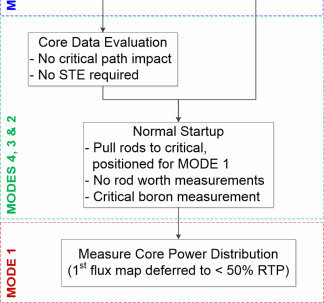

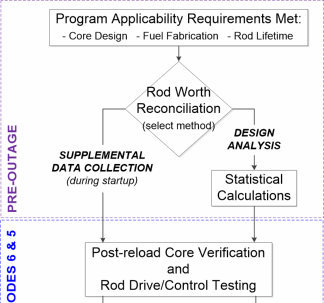

Control rod worth measurements are replaced with pre-outage statistical analysis of predicted worth and evaluation of related as-built core observations within the standard refueling outage scope, all of which enables a normal reactor startup (i.e., akin to a mid-cycle startup). The project scope also includes a detectability study of the overall, re-defined ARWV-based startup test program from MODE 6 to MODE 1 (without rod worth tests) to confirm that the ARWV program’s ability to identify safety-significant issues is greater than or equal to that of the Owner’s current startup test program.

Execution of the ARWV-based startup program is modelled after a traditional reload startup physics test sequence and therefore remains true to the overall intent of long-standing industry standard guidance (e.g., ANSI/ANS-19.6.1).

ARWV delivers wide-ranging value

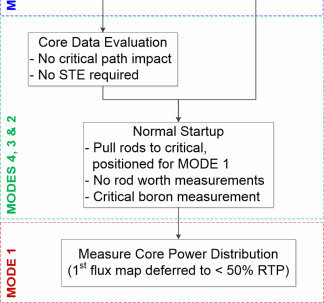

ARWV eliminates all critical path time associated with rod worth tests and related activities. If all ARWV program requirements are met, the first post-reload power distribution measurement can be deferred to 50 percent rated thermal power (RTP).

The ARWV program does not require a reactivity computer – i.e., special test equipment (STE) to perform advanced rod worth measurement techniques. Therefore, all tasks associated with STE transport, staging, calibration, connection, operation and maintenance, as well as all associated maintenance or instrumentation and control (I&C) support are eliminated1.

The ARWV approach intentionally avoids any complex or time-sensitive operator actions to minimize the risk of a reactivity or human performance event. In turn, this enables the plant Owner to minimize infrequently performed test and evolution controls during reactor startup.

Simplified flowchart for an optimized, ARWV-based reload startup test program

Deliverables

Standard project scope includes an initial evaluation of the owner’s current licensing basis to identify barriers to ARWV implementation without a license amendment request.

Following review of the owner’s existing startup test program and operating experience, a formal technical report is provided to include:

- The ARWV-based startup test program description and results evaluation criteria

- ARWV conditional applicability requirements

- ARWV implementation for use by the Owner in generating plant procedures

- Change impact evaluation, including results of the detectability study

- Input to a plant-specific 10 CFR 50.59 screen/evaluation

Experience

The ARWV approach is founded on statistical analysis of Westinghouse’s extensive global rod worth measurement experience. Since the mid 1990’s advanced Westinghouse methods have been used to support over 400 successful plant startups (encompassing over 3,000 control rod bank measurements) in six countries. This enables ARWV implementation on a vast array of cycle lengths, fuel enrichments, feed fuel fractions, and fuel and component types.

The ARWV approach draws on the precedence of the Startup Test Activity Reduction (STAR) methodology2, which was developed for the Combustion Engineering (CE) Nuclear Steam Supply System (NSSS) fleet in the early 2000’s.

The CE STAR Program was approved by the United States (U.S.) Nuclear Regulatory Commission (NRC) in 2005. To date, the STAR method has been successfully applied on eleven CE NSSS units at seven U.S. stations.

The ARWV program framework was developed in cooperation with and endorsed by the Pressurized Water Reactor Owners Group Analysis Committee in 2018-2019 as part of their efforts to optimize reload startup physics testing. In 2019-2020, Westinghouse offered and delivered the ARWV methodology to its first U.S. commercial customer.

1 Use of a reactivity computer may be required for temperature coefficient surveillance purposes.

2 The ARWV program is not a direct extension of the generic NRC-licensed STAR program.