Background

Westinghouse’s AXIOM® alloy is our next generation of fuel rod cladding material developed for demanding fuel duties and higher burnups. AXIOM cladding provides improved corrosion resistance and hydrogen pick-up performance, while maintaining excellent dimensional stability and superior resistance to aggressive coolant chemistry conditions.

AXIOM cladding is being licensed for use in all approved Westinghouse and Combustion Engineering (CE) Pressurized Water Reactor (PWR) fuel designs and corresponding rod dimensions.

Description

AXIOM cladding was developed based on the successes of Westinghouse’s Optimized ZIRLOTM cladding, and was achieved through extensive materials research, optimization and robust testing.

AXIOM provides additional benefits compared to the Optimized ZIRLO product. These include:

- 50 percent less corrosion and reduced hydrogen pickup

- Improved resistance to pellet-cladding interaction (PCI)

- Robust performance in aggressive coolant chemistry

- Enables >70 GWD/MTU burnup and supports high enrichment implementation

The advantages of AXIOM cladding are fully realized in PWR high-burnup conditions. At low to intermediate burnups, AXIOM cladding performs similarly to other successful Westinghouse cladding products.

Technical Advantages

- Dimensional stability

- Lower hydrogen pickup

- Lower corrosion at higher burnups

- Lower creep rate delays pellet-clad contact resulting in PCI margin increase

- Greater flexibility for coolant chemistry changes (Zn, Li, etc.)

- Supports extended burnup, higher duty, operational flexibility

- Increased thermal margin at higher boiling duties

- Recovery of lost margin due to thermal conductivity degradation (TCD), due to reduced oxide layer

- Increased margin with expected 10 CFR 50.46(c) rule changes

Experience

Westinghouse has successful global experience with AXIOM lead test rods (LTR) and lead test assemblies (LTA) in Europe and in United States, with successful completion of production qualification. AXIOM cladding fuel rods have been irradiated in reactors globally achieving burnup levels up to 75 GWd/MTU.

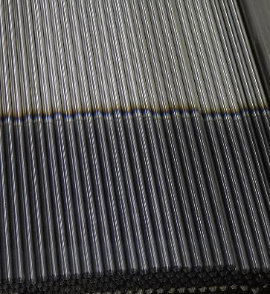

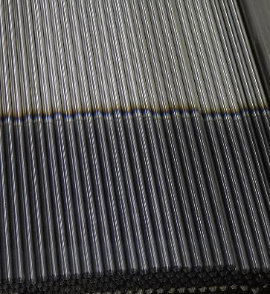

AXIOM fuel tubes

AXIOM fuel tubes

Key Features

Improved Corrosion Resistance and Hydrogen Pickup Performance

- Reduced tin content further reduces corrosion, demonstrated by improved in-reactor performance

- Reduced hydrogen pickup due to positive effect of innovative major alloying elements: niobium, copper and vanadium

Excellent Dimensional Stability

- In-reactor dimensional stability allows for lower axial growth and lower diametral creep strain

- Retains high ductility after high burnup irradiation

Superior Resistance to Aggressive Coolant Chemistry Conditions

- Designed to have robust performance at aggressive coolant chemistry conditions

- The superior resistance to aggressive conditions exceeding those currently allowable in operating PWRs including the effects of elevated pH, high power rating, and significant subcooled boiling

AXIOM fuel tubing on oxide coater

Roadmap

The submittal of a licensing topical report to the U.S. Nuclear Regulatory Commission (NRC) to generically license AXIOM cladding in early 2021 results in an anticipated NRC approval in 2023/2024. The AXIOM cladding program is in the final stage of lead use assembly irradiation demonstration.

AXIOM, Optimized ZIRLO and ZIRLO are trademarks or registered trademarks of Westinghouse Electric Company LLC, its affiliates and/or its subsidiaries in the United States and may be registered in other countries throughout the world. All rights reserved. Unauthorized use is strictly prohibited.