Background

Excessive boiling water reactor (BWR) channel distortion has become a significant operational issue affecting BWR plants in the United States. If not properly managed, excessive channel distortion can increase the risk of safety-related disruptions.

BWR channel distortion may affect control blade insertion and withdrawal times. When channel distortion is excessive, the size of the control blade path is decreased, thus increasing friction between the control blades and the channels.

Westinghouse’s BWR fuel channel distortion measuring system (FCMS) allows BWR operators to quickly quantify the amount of channel distortion with any of the fuel assembly types currently used in BWR plants, independent of the fuel vendor.

Dimensional knowledge of the channel geometry allows the customer to verify that an adequate safety margin exists to control blade insertion. By using multiple non-contact ultrasonic transducers, the Westinghouse BWR fuel channel distortion system allows efficient characterization of the geometry of any BWR channel in use worldwide.

Description

The Westinghouse FCMS is a computerized data acquisition system used to determine the fuel assembly and channel geometry of all BWR fuel designs available today, and is adaptable to future designs. The system supports a BWR fuel assembly along with multiple ultrasonic transducers used for time-of-flight measurements. The system also includes an electrical console, pneumatic control box and laptop computer, and is used for system data acquisition and calculations.

Campaign Facts

- Typically 50 to 60 fuel assemblies are measured during a campaign

- Typically four to six fuel assemblies are measured per hour, including transport of the fuel assemblies

- Results can be used for follow-up and decisions for rechanneling

- More than 2,500 measurements performed over the last decade

Equipment Facts

- Seven measuring levels, 2x5 ultrasonic transducers per level

- Two temperature transducers

- Measurement fixture simulates a core position

- Measurement time is approximately 60 seconds

- Prompt presentation of results

- Accuracy of ±0.4mm for bow, twist and bulge

- Material is stainless steel

- Weight: 1,146 lbs (520 kg), including support

Benefits

The Westinghouse FCMS performs efficient and comprehensive characterization of all existing BWR fuel channels from any supplier, allowing utilities to make conservative decisions regarding core design without impacting outage time.

Experience

The Westinghouse FCMS has been measuring channel geometry (from multiple fuel suppliers) for over a decade at BWR plants located in the United States and Europe.

Fuel channel measurement system fixture

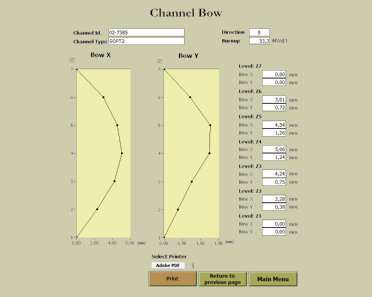

Channel bow measurements of a BWR assembly in the Westinghouse FCMS

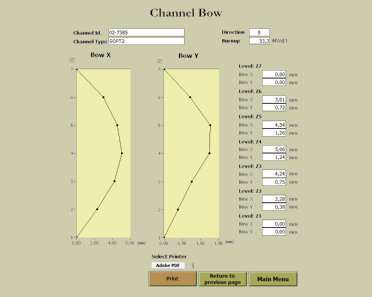

Channel bow measurements of a BWR assembly in the Westinghouse FCMS