Background

Westinghouse has a proven tool to provide solutions to many common emergent and long-term utility concerns. Westinghouse’s CE Nuclear Transient Simulator (CENTS) code is a U.S. Nuclear Regulatory Commission (NRC) licensed best-estimate analysis code that can be used in a variety of pressurized water reactor (PWR) and boiling water reactor (BWR) applications.

The CENTS code originated as the model set for a PWR full-scope simulator. As such, it has been used on numerous full-scope training simulations, and individual models have been used in many other simulators, including those for BWRs. CENTS is based on detailed first-principles models for one- and two-phase fluids. Use of nonequilibrium, nonhomogeneous models allows a full range of fluid conditions to be represented, including forced circulation, natural circulation, coolant voiding and presence of noncondensable gases. The code provides a comprehensive set of interactions among the analyst, the reactor control systems and the reactor.

Description

The CENTS computer code simulates the transient behavior of PWRs and BWRs for all normal, abnormal and accident conditions. It is an interactive, faster-than-real-time code capable of running on multiple computer platforms. Although fully approved by the NRC for licensing basis accident analyses, it retains all the features required for accurate best-estimate plant simulation.

CENTS fully models the nuclear steam supply system and most related PWR and BWR plant systems. It can track radionuclide concentrations and noncondensable gases throughout the plant. The code is robust in accurately modeling all modes of plant operation, including outage conditions at low temperature and atmospheric pressure.

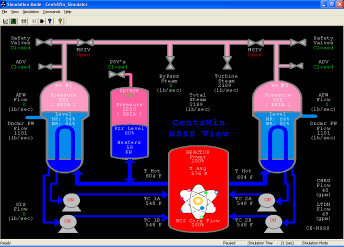

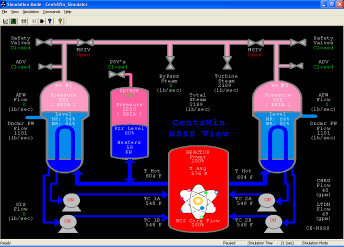

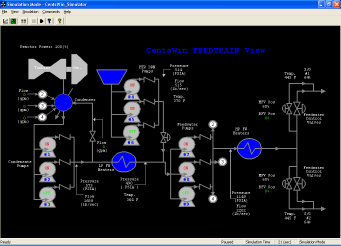

First-generation graphical user interface – nuclear steam supply system view

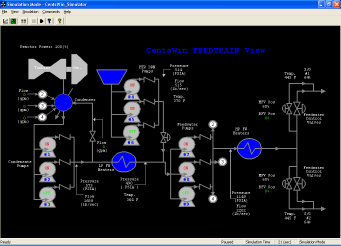

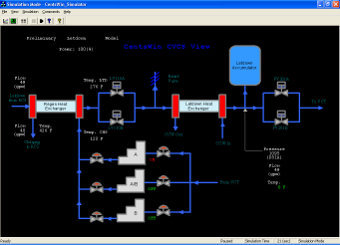

Feedtrain system

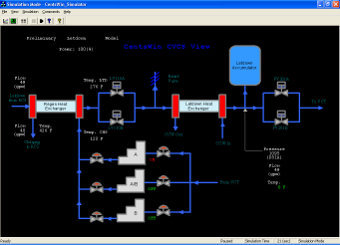

Chemical and volume control system

Benefits

CENTS can be used to provide the following solution services to utilities, independent of the fuel vendor. CENTS can:

- Increase operating margin

- Evaluate potential system and component upgrades

- Quantify margin gained from equipment updates

- Model realistic natural circulation cooldown and condensate storage tank sizing

- Remove excessive analytical conservatism from existing analyses such as anticipated transient without scram

- Provide troubleshooting support

- Troubleshoot control system malfunctions, control setpoints drift, and pressurizer-heaters/sprayers operation and tuning

- Provide detailed full nuclear steam supply systems support systems modeling and full plant event modeling

- Assist with outage planning

- Optimize pre-planned responses to shutdown issues

- Reduce shutdown risk by evaluating and validating mitigating actions

- Evaluate safety implications and optimize timing of critical steps

- Evaluate reactor coolant system fluid system performance Evaluate the performance impact of equipment changes, tube plugging, pump upgrades, plant simplification, pipe losses and flow-test benchmarking

- Improve operating procedures Optimize procedure change

- Improve timing of operator actions

- Validate current procedures

- Provide operator simulator training

- Convert to symptom-based emergency operating procedure format

- Refine operating procedures for various scenarios such as once-through core cooling and feed and bleed

- Increase outage flexibility Evaluate loss of shutdown cooling at various conditions

- Track and extend time-to-boil at various outage conditions (mid-loop, upper head removed, etc.)

- Optimize plant shutdown timing

- Improve spent fuel pool time-to-boil

- Provide feedwater and steam generator level control Optimize control system setpoint

- Provide control system tuning and improvement, including steam generator level control, feed pump speed control, pump variable frequency drive and steam dump and bypass control after shutdown

- Support compliance with new NRC requirements Evaluate extended loss of AC power

- Respond to NRC Show Cause notices

- Perform American Nuclear Society/American National Standards Institute 3.5 simulator validation

- Assist with spent fuel management Conduct spent fuel pool constraint analysis (decay heat, dose, conform to criticality, etc.)

- Develop plant-specific cross-sectional libraries

- Determine assembly qualification for cask loading (long-term storage or transportation)

Numerous plant concerns can be solved using one CENTS model. In addition, CENTS provides the following benefits:

- Is capable of 10 times real-time event speed, enabling effective, prompt outage troubleshooting support

- Determines accurate impacts and benefits of equipment modifications in advance of the procurement process

- Validates procedures accurately by using only the indications available to an operator

Experience

Westinghouse has more than 30 years of experience using CENTS for desktop simulations of a number of nuclear power plants and in full-scope simulations and control systems design and optimization. CENTS also has been used to perform advanced design work, including work on the Westinghouse AP1000® new plant design.

AP1000 is a trademark or registered trademark of Westinghouse Electric Company LLC, its affiliates and/or its subsidiaries in the United States and may be registered in other countries throughout the world. All rights reserved. Unauthorized use is strictly prohibited.