Background

Westinghouse developed the CE16NGFTM next generation nuclear fuel assembly for 16x16 Combustion Engineering nuclear steam supply system (CE-NSSS) style reactors to improve fuel performance, especially at high-duty operation, enhance fuel reliability and provide additional value to users through power upratings, improved operability and favorable fuel cycle economics.

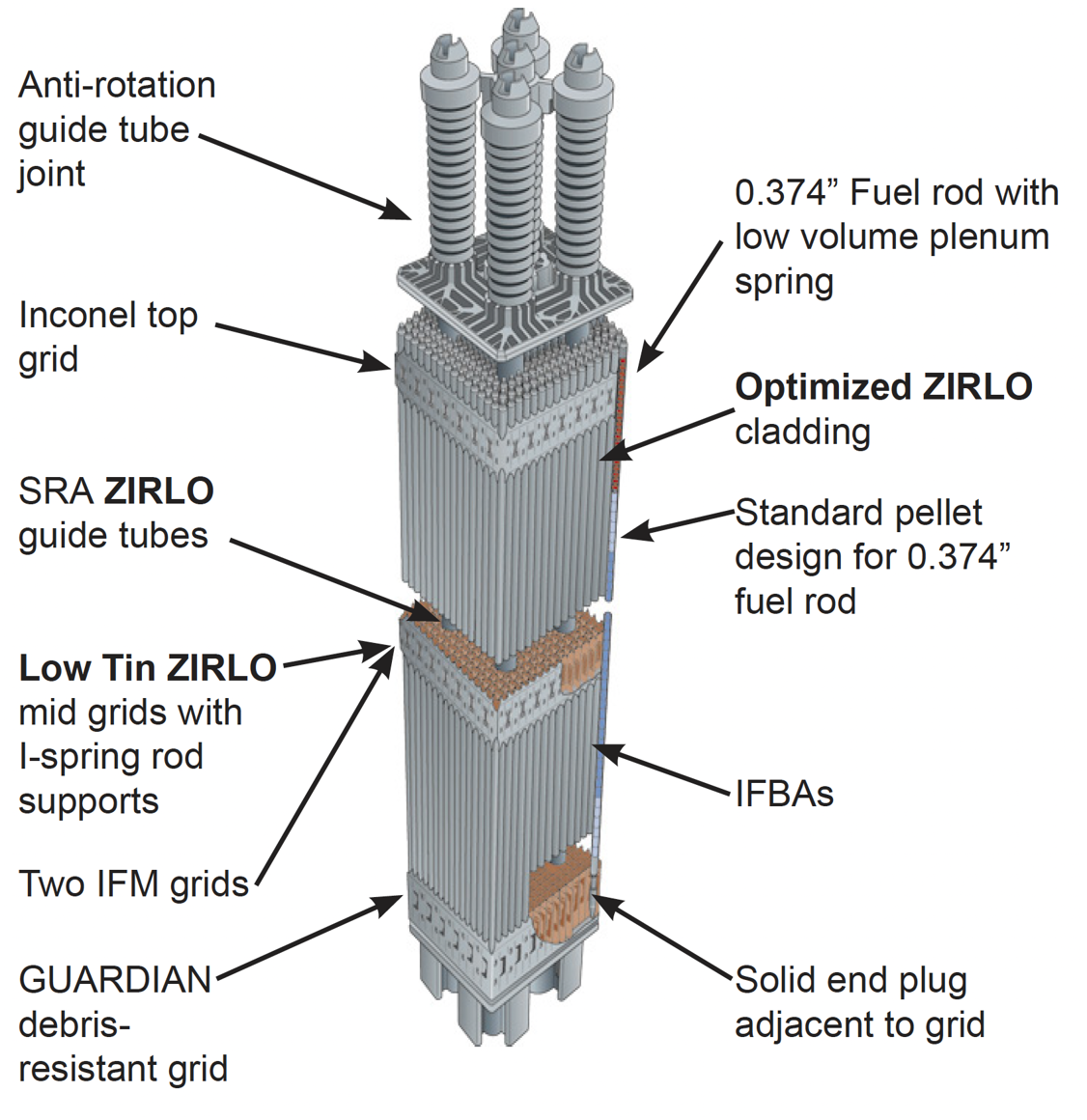

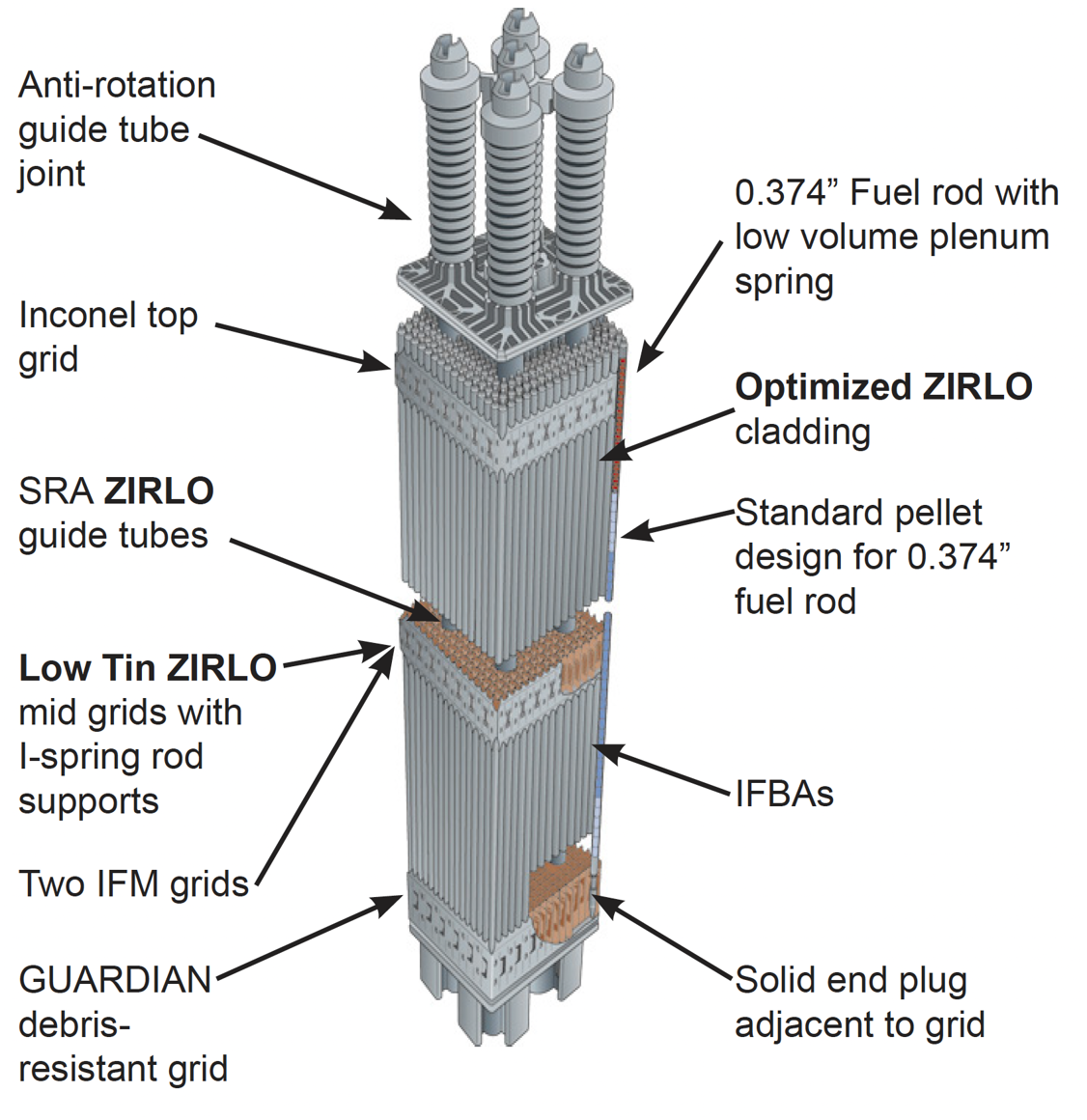

CE16NGF fuel key design features include:

- Westinghouse-patented integral fuel burnable absorber (IFBA) zirconium diboride (ZrB2) burnable absorber fuel rods for improved fuel cycle economics.

- Advanced mid-grids with I-spring rod supports and side-supported mixing vanes at selected elevations to improve crud, corrosion, and grid-to-rod fretting performance and thermal margin.

- Addition of two intermediate flow mixing (IFM) grids at selected axial locations to improve crud, corrosion and grid-to-rod fretting performance and thermal margin.

- A reduced rod bow top grid made from Inconel to improve grid-to-rod fretting margin at that elevation.

- GUARDIAN™bottom grid and a solid, long lower-end plug on the fuel rods, which have a record of good debris mitigation and fretting performance.

- Optimized ZIRLO™ high-performance fuel cladding material for improved crud and corrosion resistance and dimensional stability.

- Stress relief annealed (SRA) ZIRLO® guide tubes for improved dimensional stability.

- Low Tin ZIRLOTM grid strap material for improved corrosion resistance and dimensional stability.

- Anti-rotation guide tube joints for improved structural integrity, especially during fabrication and, if needed, inspection and reconstitution activities.

Description

The following figure provides an overview of the features of the CE16NGF fuel design. The figure is for illustrative purposes only and does not depict the customization aspects that are required for each specific 16x16 CE-NSSS reactor design.

Benefits

The CE16NGF fuel design has demonstrated good grid-to-rod fretting and thermal margin performance in reactor use. Field inspections of post-irradiated fuel rods have shown low fuel rod wear, and the design has not had a fuel leak due to grid-to-rod fretting since its deployment.

The Westinghouse CE16NGF fuel design is supported by our highly experienced engineering and manufacturing teams, which are available to address customer operational needs and emergent issues.

Experience

Westinghouse has been delivering the CE16NGF fuel design in region quantities since 2008. Lead use assemblies (LUAs) were deployed in a 16x16 CE-NSSS reactor for testing in 2005 and these LUAs demonstrated good in-reactor performance.

In addition, plants using the CE16NGF fuel design with IFBA (ZrB2) as the burnable absorber in the fuel rods have achieved favorable fuel cycle economics.

Westinghouse CE16NGF fuel assemblies (over 700 to date) thus have a proven track record of good performance in reactor use.

CE16NGF fuel design features