Background

In recent years, fuel assembly channel bow has become a serious concern to the boiling water reactor (BWR) industry. The acceleration of this phenomenon is generally caused by increasing discharge burnups, and is further enhanced by the mechanisms of control blade shadow corrosion in plants that have transitioned to 24-month cycles. This poses new challenges to the evaluation of thermal margins, in particular the critical power ratio (CPR).

Traditionally, the impact of channel bow on CPR margins has been evaluated using analytical methods, treating the channel bow as a core average property and applying a conservative penalty factor to each fuel assembly. However, such methods are inappropriate when the magnitude of the channel bow varies significantly across the core, and the results tend to be overly conservative.

Description

McSLAP is a Monte Carlo code to statistically determine lower limits for the core minimum critical power ratio (MCPR) corresponding to given dryout criteria. For instance, the safety limit MCPR (SLMCPR) can be determined with the criterion of, at most, a 0.1 percent fraction of fuel rods expected in dryout. This is a widely accepted criterion that is applied to provide dryout safety during transients, as well as during normal operation. McSLAP also has the unique capability of handling the influence of channel bow when establishing the core MCPR limits. This is done in a best-estimate approach, based on measured channel bow data and a general understanding of the channel bow phenomenon, and with the help of a detailed modeling of the fuel assembly lattice perturbations.

Benefits

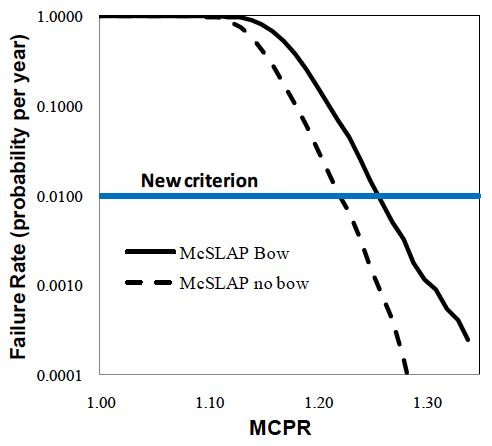

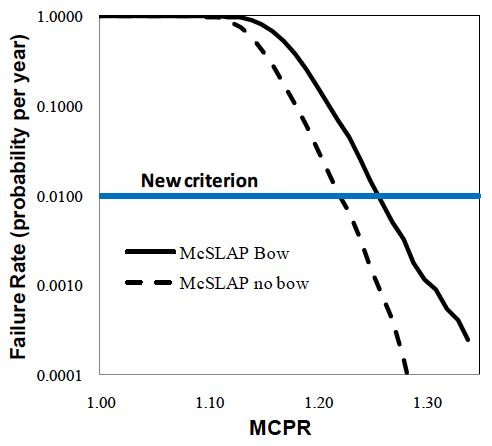

The McSLAP code, in combination with the Westinghouse CPR methodology that applies a new and more appropriate criterion to protect the core against dryout during normal operation (requiring the failure rate probability to be less than 0.01 per year), offers the following distinct advantages:

- A comprehensive methodology handling relevant aspects

- Accurate and complete statistical treatment of channel bow effects with no need for additional CPR penalties during core supervision.

- Direct quantification of the value of reducing channel bow in the core in terms of improved CPR margins

- A new, improved CPR criterion for normal operation to give a balanced risk of dryout, considering both probability and consequence

- Improved quality of dryout safety assessments – a best-estimate statistical approach with McSLAP allowing consistent treatment of the uncertainties affecting CPR, with a comprehensible and controllable level of conservatism

In summary, McSLAP can properly verify the criterion of 0.1 percent fraction of fuel rods expected in dryout, provide and evaluate a more appropriate dryout criterion for normal operation, and account for the detailed effects of channel bow on dryout risk in a best-estimate manner.

Experience

The Monte Carlo method implemented in McSLAP has been extensively validated, and the code has been applied to determine the SLMCPR for numerous power plants in both Europe and the United States over a period of almost two decades. McSLAP is approved for SLMCPR evaluation in the United States, Sweden, Finland and Switzerland..

The new dryout criterion for normal operation, uniquely available with McSLAP, has been thoroughly evaluated and demonstrated with applications to different European plants. The criterion has been approved in Switzerland to replace the previous MASL100 criterion and in Sweden to replace the 4-sigma criterion.

For more information, please refer to:

S. Baumgartner, R. Bieli and U.C. Bergmann, “CPR methodology with new steady-state criterion and more accurate statistical treatment of channel bow,” in proceedings from PHYSOR 2012, Knoxville, Tennessee, USA, April 15-20, 2012.

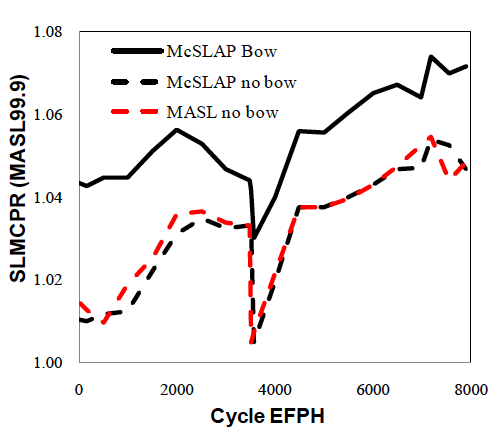

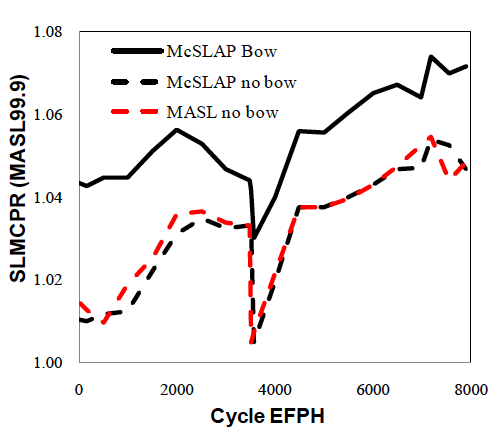

In the following graphics, example results are shown with and without the impact from channel bow.

Evolution of the SLMCPR throughout a cycle

Dryout failure rate evaluated as a probability of steady-state dryout per year.