Background

Westinghouse Criticality Safety Services assess the margins to criticality, promoting safe and cost-effective storage, handling and transportation of pressurized water reactor (PWR) and boiling water reactor (BWR) nuclear fuel products. Criticality Safety Services provide explicit and complete analyses of fresh and spent nuclear fuel configurations, including extensive documentation and licensing support. All analyses are performed under the Westinghouse Quality Management System (QMS), providing verification and validation of all analysis and documentation activities.

Description

Westinghouse Criticality Safety Services help plant operators effectively manage fuel-storage and handling options by determining safe-storage limits for nuclear fuel in a variety of configurations. For example, if the customer’s fuel storage options are exhausted, or if a plant change related to an uprate and/or a fuel transition influences a criticality change, the need to perform a new analysis increase.

The services analyze fuel that is located in the following:

- Spent-fuel-pool storage racks

- Fresh-fuel vaults

- In-containment storage racks

- Fuel inspection equipment

- Submerged storage casks

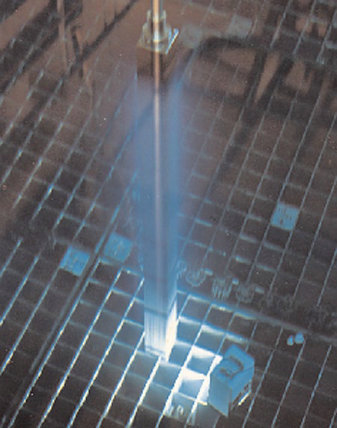

- Reactor cores

- Fuel transportation canisters

Westinghouse Criticality Safety Services capabilities include:

- Considering burnable fuel absorbers (i.e., ZrB2, Er2O3 and Gd2O3)

- Analyzing new operational strategies, such as 24- month fuel cycles

- Displaying discrete three-dimensional determination of depletion effects on the reactivity of spent fuel assemblies

- Considering uncertainties in fuel composition, depletion, and environment

- Increasing criticality margins by explicit representation of fixed-neutron absorbers

- Considering reactivity credit due to the presence of soluble boron in water, eliminating the need to consider degraded Boraflex absorbers

- Displaying a representation of the environment after analyzing postulated accident scenarios

- Providing robust analysis documentation and licensing support

Benefits

Westinghouse Criticality Safety Services can minimize plant operator costs associated with nuclear fuel storage, handling, and transportation. These services provide customers with the following:

- Operational flexibility when handling and transporting spent fuel

- Elimination of Boraflex credit, without a substantial loss of storage capacity, through the use of soluble boron credit

- Additional storage capacity for previously exhausted spent-fuel storage options

- Delay of independent spent-fuel storage installations (ISFSI)/dry storage cask transfer, thereby increasing the return on investment of a spent-fuel pool

- Ease of licensing due to extensive documentation and expert licensing support

Features

- By aligning criticality analysis and a fuel vendor, the need to supply preliminary specifications for criticality analysis is eliminated, minimizing utility costs

- Tools and methods used are extensively benchmarked against physical experiments and are licensed by the U.S. Nuclear Regulatory Commission

- Westinghouse has over 40 years of experience in providing criticality services to nuclear fuel customers worldwide

- Final criticality analyses coordinate with other Westinghouse products (e.g., TRACWORKS®, a Westinghouse fuel data management software used to automate fuel data management) for ease of managing optimal configurations

TRACWORKS is a trademark or registered trademark of Westinghouse Electric Company LLC, its affiliates and/or its subsidiaries in the United States of America and may be registered in other countries throughout the world. All rights reserved. Unauthorized use is strictly prohibited. Other names may be trademarks of their respective owners.