The Westinghouse Solution

Westinghouse is best positioned to execute a new nuclear technology development, from design, licensing, plant startup and commissioning and ongoing technical support for plant operations.

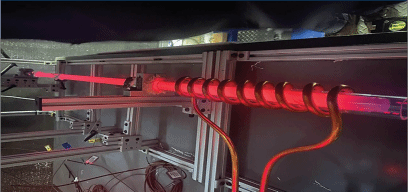

As Westinghouse continues the development of eVinci based on heat pipe technology, the advancements being made continue to reinforce how versatile heat pipe-based reactor technology is when compared to competing ideas for mobile nuclear power. Heat pipe technology has been applied for the past 50-60 years with millions of operating hours in aerospace and other industries in high temperature applications which rely on the passive and simplified component design for nuclear application development.

Customer Benefits

Westinghouse has developed and continues to advance heat pipe technology and manufacturing processes through design, analysis tools and test capabilities. Westinghouse has also developed proprietary manufacturing processes for high performance heat pipes based on strict quality- controlled techniques, procedures, and tooling.

Westinghouse’s high-quality manufacturing processes, including fabrication in inert environments, strict cleaning and inspection processes throughout assembly, and leading material sourcing promote success for a scalable technology based on proven science and demonstrated components. Westinghouse’s heat pipe technology has set performance records during long- term testing.

Heat Pipe Design Benefits

- Allows for greatly simplified systems and operations with unparalleled reliability

- Eliminates significant failure modes and additional systems associated with active systems

- Eliminates risk from high system pressures and loss of coolant accidents

- Eliminates flow induced corrosion and vibration typical of forced flow systems

- Enables prototypic life testing at operating temperatures