Combining Research Flexibility with Campus-wide Heat and Power

| 1.0 |

Neutron Activation Analysis (NAA) |

| 1.1 Instrumental NAA (INAA) |

| 1.2 Prompt Gamma NAA (PGNAA) |

| 2.0 |

Radioisotope Production |

| 3.0 |

Neutron Imaging |

| 4.0 |

Testing |

| 4.1 Instrument Testing and Calibration |

| 4.2 Neutron Irradiation |

| 5.0 |

High Temperature Research |

| 5.1 Thermal Testing, Thermal Cycling, Thermal Aging |

| 6.0 |

Energy Applications and Demonstrations |

| 6.1 Desalination Plants, Hydrogen Production, Vertical Farming |

| 7.0 |

Education and Training |

| 7.1 Supporting Physics, Biology, Nuclear Engineering, Radiation Protection and Radiological Engineering programs |

| 7.2 Public Tours and Visits |

| 7.3 NPP Operator Training |

The Westinghouse Solution

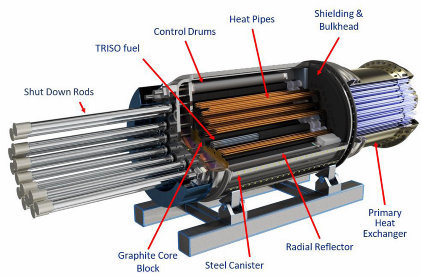

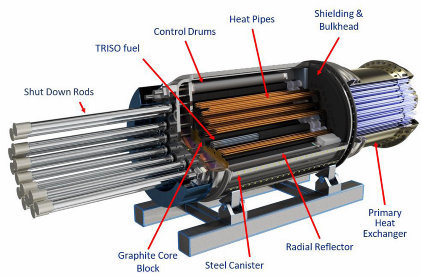

The eVinci™ Microreactor provides a cost competitive, flexible and resilient source of power and heat while enabling active nuclear research opportunities. The eVinci small size allows for flexible transportability and rapid on-site deployment.Westinghouse combines new technology with over 60 years of nuclear design and engineering experience to support research applications.

Key features:

- 5MWe and 6MWth at 150C

- 8+ year fuel life

- Seamless pairing with existing grid

- Above ground installation with no water required for operation

- Compact, factory-built design allows for rapid and flexible installation

eVinci Research Applications

eVinci Microreactor Advanced Nuclear Technology Design

Offering Heat and Power Flexibility for your Research & Facility Operating Needs

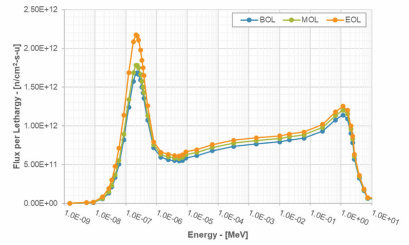

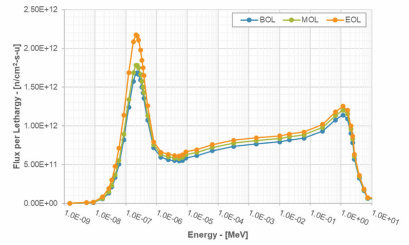

eVinci™ Neutron Flux Profile

The flux profile across the life of the eVinci reactor provides consistency and research flexibility

eVinci™ Flux profile across reactors life: BOL - beginning of life, MOL - middle of life, EOL - end of life

- In-Core Flux is on the order of 1x1013 n/cm2

- Ex-Core Flux is on the order of 1x1010 to 1x1012 n/cm2 depending on location

- Current concept can accommodate 12 irradiation sites, each ~5 cm in diameter

- Additional larger positions up to 12–15 cm in diameter can likely be accommodated with further core design changes

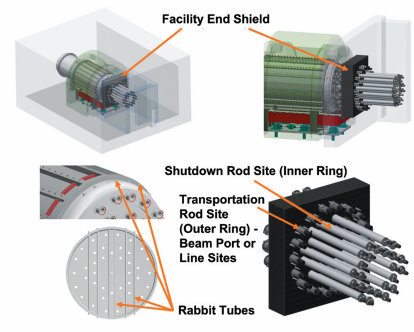

Plant Layout Concept

- Large Irradiation needs: Horizontal transportation safety rods will be removed and repurposed as beam ports or beam line sites

- Small Irradiation needs: Perpendicular vertical irradiation (Rabbit Tubes) tubes thread between shutdown rods on the reactor face can address different irradiation needs

- Shutdown rods remain in place for operational safety, along with supplemental custom shielding

- Due to shielding and safety design, room can be accessed for maintenance or upgrades to the facility

- Reactor can remain fully operational producing power and heat while enabling research reactor services