Background

Operating nuclear plants are required to perform various Non-Destructive Examinations (NDE) of their Reactor Vessel Heads (RVHs) in accordance with federal regulations and ASME Code Section XI.

Utilities perform these Reactor Vessel Head Inspections (RVHIs) at regular frequencies, depending on the design and material of the RVH. The focus of the exams is primarily on the j-groove welds of the RVH penetrations, but may also include thermal sleeves, or other components related to the penetrations. The NDE techniques deployed are typically Ultrasonic Testing (UT), Eddy Current Testing (ET), or Visual Testing (VT).

Description

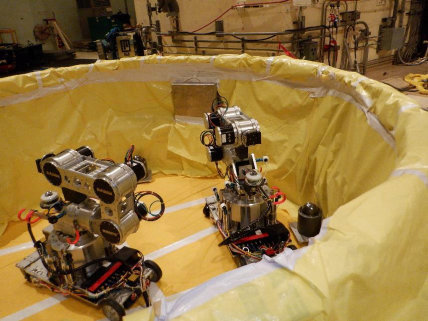

Consisting of two mobile inspection platforms, the Gemini system delivers simultaneous penetration inspections improving the inspection duration and reducing cost to the customer.

The system is designed to be universal in nature to inspect both CE and Westinghouse style reactor vessel heads.

The Gemini system is also designed to be adaptable to various RVH and stand configurations and is capable of installation through most headstands while the head is on the headstand.

Incorporation of position tracking technology within the headstand and a telescopic column for increased reach add to the functionality of the Gemini System.

Benefits

The Gemini system can perform inspections in parallel under the RVH, while the RVH is in its headstand during an outage. This feature drives over 40% improvement to the utility outage project exam schedule.

The Gemini system can also be installed/removed through most RV head stand manways and windows. This feature will reduce time on site, reducing delay fees to customers. This feature will also support emergent inspections.

The Gemini’s innovative technology and capabilities help our customers reduce their outage schedule and dose rates. Coupled with Westinghouse’s superior NDE techniques, the Gemini system has put Westinghouse ahead of the competition with an improved exam schedule and reduced costs to customers.

Deliverables

The Gemini system provides a variety of NDE applications utilizing a dual robot system that can deliver various NDE tools, depending on the required exam (i.e. UT, VT, thermal sleeve thickness, etc.).

Experience

Westinghouse has been performing RVHIs for over 20 years, with a proven track record in implementation and superior NDE techniques. The Gemini delivery system utilizes these proven NDE techniques with its new advanced robotic delivery system.

The Gemini delivery system was successfully implemented during the Spring 2020 outage season.