The Westinghouse Solution

Westinghouse Electric Canada provides a suite of customized solutions and specializes in the design, development and manufacturing of high-reliability, custom-engineered systems for the nuclear industry. Our commitment to nuclear is demonstrated by over 45 years of experience, including more than 2,500 contracts for CANDU® utilities both in Canada and globally.

From design-build or build-to-print projects and everything in between, our in-house facility in Peterborough, Canada is equipped and staffed for success. Specializing in CANDU® projects, the facility contains both conventional and CNC machining capabilities as well as in-house dimensional inspection and non-destructive examination and testing.

Capabilities

Our Westinghouse Peterborough facility is housed on a 3.3-acre lot and includes both office space for engineering, design, quality, procurement, manufacturing professionals and project managers as well as the manufacturing plant.

- Manufacturing plant covers more than 36,000 square feet including a 30-ton crane and 50 feet of clearance

- Conventional and CNC machining capabilities

- Dimensional inspection

- Non-destructive examination and testing (liquid penetrant, magnetic particle, helium leak testing, pneumatic and hydrostatic testing)

- In-house seismic and EMC testing supports Commercial Grade Dedication work

- Certified to CSA N285.0, B51, and CWB W47.1, W47.2

Facilities Overview

The manufacturing area is divided into three bays and Bay 1 and Bay 2 have a flexible design to accommodate project demands (assembly, welding, testing of skid mounted process systems and electro-mechanical manipulators).

- Bay 1 is used for structural welding of large fabrications, assembly of large systems and is serviced by 25-ton and 15-ton overhead cranes. The under-hook height of the crane is approximately 29 ft.

- Bay 2 is used for assembly of larger fabrications requiring additional height and is serviced by a 30- ton overhead crane and a light duty 5-ton. The under-hook height of the bay 2 crane is approximately 50 ft.

- Bay 3 includes a machine shop area with CNC and conventional machining centers, a stores and parts staging area, shipping receiving, inspection, and NDE area. This bay is serviced by a 6-ton overhead crane with an under the hook height of approximately 15 ft.

One Stop Shop: Design to Manufacturing

Our facility houses our support staff, engineering, design, and manufacturing all under the same roof. This makes for seamless project execution and is key for "design for manufacture" whereby our designers and engineers work hand-in-hand with the manufacturing team.

Manufacturing Services

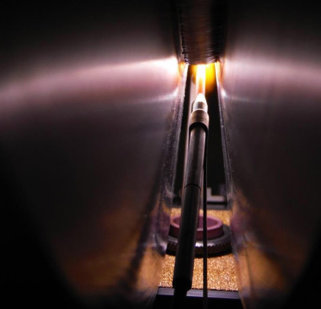

Welding

Manual, automatic & semi-automatic welding

- GTAW, SMAW, GMAW, FCAW, and Brazing Pulsed ARC

- Low Hydrogen electrodes (c/w condition ovens)

- Welding of common and exotic materials

- Overhead crane welding positions

Welding program meets ASME Section III, Section VIII and ASME Section IX. We have qualified procedures for:

- Stainless steel

- Aluminum

- Hastelloy

- Titanium

- Carbon steel (with and without PWHT)

- Inconel

- Tantalum

- Certified to CSA N285.0 and B51 (equivalent to ASME Section III, VIII and IX for CANDU plants)

- Certified to CWB W47.1, W.47.2

- Approx. 40 welding procedures and welders are registered with the TSSA

Machine Shop

Conventional & CNC machining capability:

- 2 Vertical CNC mills: 1 fitted with a Renishaw inspection probe

- 2 CNC Turning Centers

- 60" bed length

- 18" max. Machining dia.

- Twin Spindle

- Renishaw Inspection probe

- Horizontal Boring Mill

- Various Conventional Machines

- Mazak Vari-axis I-700 5-Axis CNC machining center

- MasterCam CNC programming software

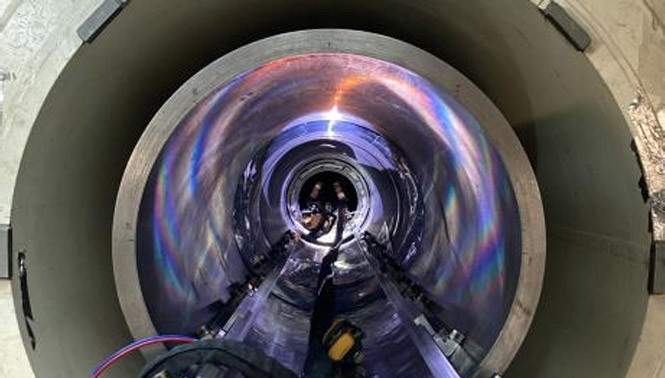

Assembly and Testing

- Precision assembly of complex electro-mechanical equipment

- Factory acceptance testing (including field mockup)

- Helium leak testing

- Hydrostatic & Pneumatic pressure testing

Inspection

Qualified inspectors employing modern equipment, including:

- Large, stationary Coordinate Measuring Machine

- FARO arm (portable CMM)

- PCDMIS software interface

NDE, CGSB Level 2:

- Liquid Penetrant Inspection

- Magnetic Particle Examination

- Eddy-current Testing

- Visual Weld Inspection

www.westinghousenuclear.com/canada/CANDU