The Westinghouse Solution

Westinghouse is committed to bringing efficient, large-scale hydrogen production to nuclear facilities through operating plant integration and advanced reactor designs. Clean hydrogen supports societal decarbonization while yielding a significant, yet flexible revenue stream to utilities around the world. Westinghouse is positioned to be a full-scale hydrogen partner, maximizing power output, modernizing plants for long term operations and monetizing hydrogen production.

Market

Global demand for hydrogen and its emerging applications is projected to increase by a factor of ten by 2050, surpassing the current infrastructure for producing and delivering hydrogen.

As hydrogen usage expands from traditional industrial applications to the fuel of a clean future, the need to produce it in larger quantities and from green sources is supported by international scientists and policy makers.

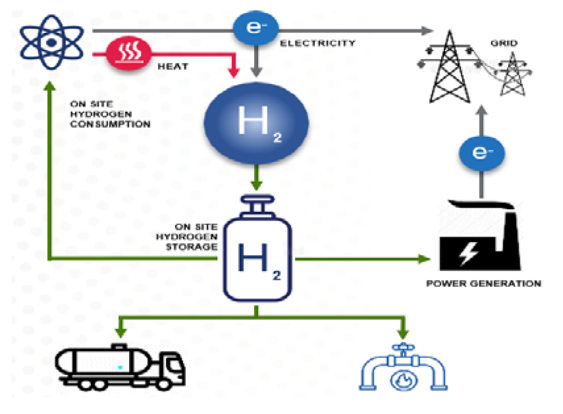

Nuclear plants, both existing and in design, large and small, are well-positioned to utilize electrolyzer technology to produce meaningful quantities of clean hydrogen with minimal disruption to operations.

Customer Benefits

Westinghouse, a premier provider of design, engineering, products, and field services to the nuclear industry, is ready to position our customers for a new source of revenue through hydrogen generation.

Westinghouse is the ideal partner to advance hydrogen efforts given our nuclear culture drives excellence and safety in all that we do. Our Pressurized and Boiling water Reactor design knowledge, licensing, and operational experience allows us to optimize hydrogen design and production. Our industry-leading instrumentation and control technologies ensure precise operability. Our extensive architect engineering and construction capabilities bring concepts to reality. Finally, our industry partnerships provide value by bringing our customers cutting-edge solutions, now and into the future.

Westinghouse’s unique qualifications allow us to protect the existing nuclear asset, while providing an appealing business case for maximizing power output, modernizing plants for long term operations and monetizing hydrogen production.

Experience

Westinghouse’s unique expertise which is essential to hydrogen production includes:

- Project Planning:

- Hydrogen production technology identification/selection

- Front End Engineering Design Study

- Uprate/major upgrades

- Full value chain engagement/support

- Implementation:

- Nuclear Steam Supply System Analysis

- Thermal, Electrical and Water Supply

- Fuel Analysis and Core design requirements

- Control System Analyses

- Control System Design and Integration (leveraging existing or new digital I&C)

- Main Control Room Human Factors Engineering (HFE) and Human Machine Interface (HMI) Integration

- Simulation/Testing

- Power Uprates and BOP modifications

- Hydrogen Explosion Analysis

- Hydrogen Drying, Compression, Storage and Transport

- Civil/Structural Construction

- Industry Experience/Supply Chain

- Relationships with Hydrogen/Chemical Vendors and Electrolyzer Suppliers

- Supplier Networks and Relationships

- Waterway/Railway Access and Transport