Background

Westinghouse’s Integral Fuel Burnable Absorber (IFBA) fuel pellet has revolutionized PWR nuclear reactor fuel management loading patterns and has enabled highly improved fuel cycle economics. Westinghouse is now building on the success of our flagship IFBA product with IFBA/Gad hybrid fuel assemblies that facilitate longer (24-month ) cycles while providing similarly improved fuel cycle cost (FCC) savings.

Description

Westinghouse’s breakthrough innovation was to coat normal production UO2 fuel pellets with thin layers of zirconium diboride (ZrB2), which we refer to as IFBA fuel pellets. Zirconium diboride’s daughter products, helium and lithium, are essentially transparent to neutrons. The absorption rate of ZrB2 is closely matched to the fuel’s reactivity depletion, so no residual penalties result.

In the operation of a PWR, it is desirable to prolong the life of the reactor core as long as feasible to better utilize the uranium fuel, thereby reducing fuel costs. To attain this objective, it is common practice to initially load into the reactor core an excess of reactivity and, at the same time, make provision for the reactivity to be maintained relatively constant throughout core life. One method of doing this is to use a burnable absorber material that has high neutron absorption during the initial period of operation and then reduces its neutron absorption ability through transformation during the later period of operation. The Westinghouse IFBA product is the optimal burnable absorber of choice for such reactivity control.

The IFBA (ZrB2) fuel pellets are normally used in combination with uncoated UO2 top and bottom blanket pellet regions in fuel rods. The blanket pellets can be either solid or annular, depending on the particular fuel cycle needs.

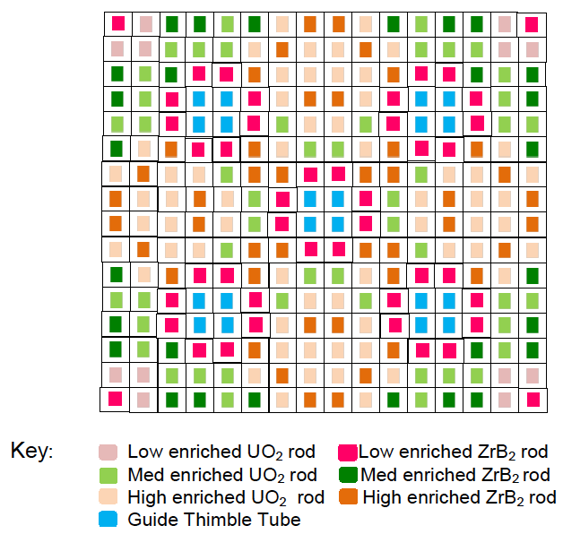

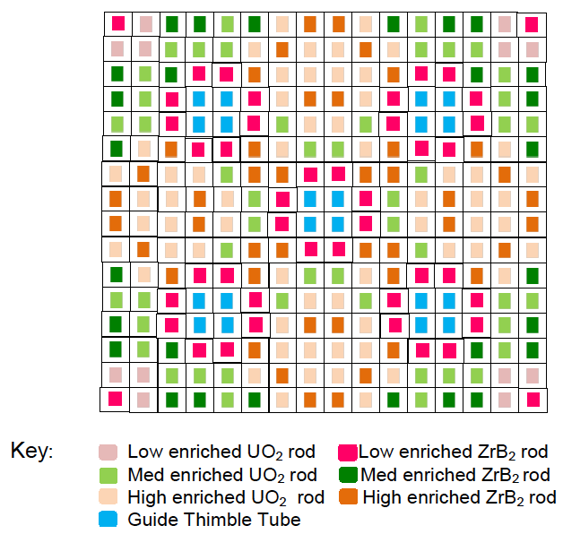

Sample IFBA Lattice Pattern

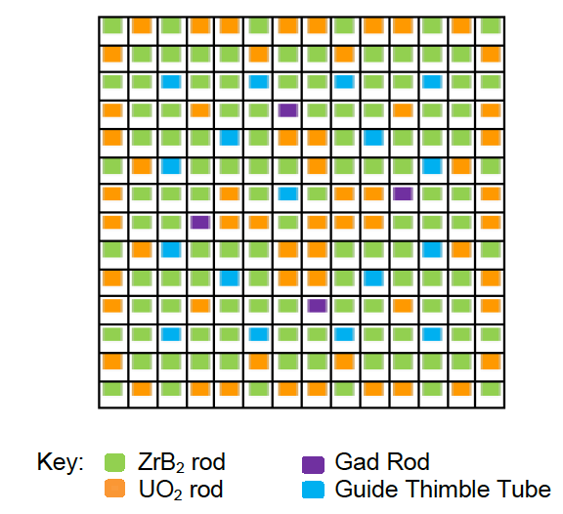

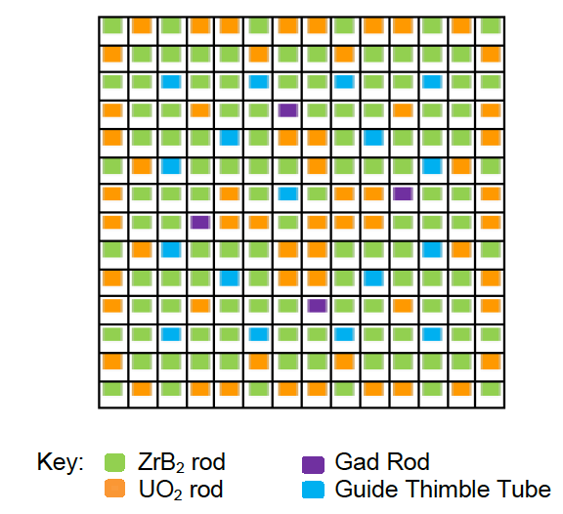

Sample IFBA/Gad Hybrid Lattice Pattern

IFBA fuel rods can be distributed in various lattice locations of a fuel assembly with other UO2 fuel rods making up the balance of the fuel assembly. Such IFBA fuel assemblies can be used in various fresh fuel core locations, along with any UO2-only fuel assemblies, to accomplish the required fuel cycle energy and power distribution requirements while providing fuel cycle cost savings due to the greater neutron utilization efficiency and resulting reduced uranium enrichment needs.

24-Month Cycles

IFBA fuel assemblies are well suited to 18-month cycles but have limitations for use in longer (24-month) cycles due to the relatively short depletion period associated with IFBA fuel. Westinghouse’s innovative solution is to add a small number of discrete gadolinia rods (UO2/Gd2O3) to a fuel assembly lattice of distributed IFBA rods, which we refer to as an IFBA/Gad Hybrid fuel assembly. This resulting product offering provides fuel cycle economic benefits while supporting longer cycle (e.g., 24 month cycle) operation. It also avoids or reduces requirements for additional hardware procurements, handling and disposal activities for auxiliary hold-down devices such as the Westinghouse Wet Annular Burnable Absorber Assembly (WABA).

An IFBA/Gad fuel assembly is composed of a combination of a distributed quantity of IFBA fuel rods, a few discrete gadolinia (UO2/Gd2O3) fuel rods and a balance of UO2 fuel rods in the fuel assembly lattice. This flexibility allows the nuclear core design to achieve 24-month cycle goals from the longer duration hold-down of the gadolinia rods, as well as the power distribution improvements and FCC savings associated with the IFBA fuel rods.

Benefits

Some of the customer benefits associated with use of IFBA fuel include:

- Potentially, more than 1.5 percent in feed ore savings and more than 1.8 percent in SWU savings relative to a comparable Gad-based core, as validated in a recent fuel cycle analysis.

- ZrB2 can be applied precisely on individual pellets and individual lengths of pellets, thus enabling a variety of options for core design and loading pattern selection that results in improved power distributions (lower peaking) during operating cycles.

Some of the utility benefits associated with use of IFBA/Gad hybrid fuel assemblies include:

- Power distribution benefits from use of a distributed quantity of IFBA fuel rods, coupled with the longer duration reactivity hold-down of a few discrete Gadolinia fuel rods in the same fuel assembly, which enable longer (e.g., 24-month) cycles.

- FCC savings due to the lack of residual penalties associated with the use of the IFBA rods.

- IFBA/Gad hybrid fuel assemblies eliminate or reduce the need for additional core component handling, movement and disposal activities required by the use of external auxiliary absorbers like WABA.

Experience

IFBA (ZrB2) fuel rods have been used successfully in Westinghouse-designed PWRs (W-NSSS) for more than 30 years. Over four million IFBA fuel rods have operated in more than 40 plants worldwide. Current IFBA fuel rod production is approximately 250,000 rods per year. IFBA fuel rods are operating in 14x14, 15x15, 16x16 and 17x17 W-NSSS and 16 x16 Combustion Engineering style (CE-NSSS) PWR reactor cores fueled by Westinghouse.

Customers are exploring the use of IFBA/Gad hybrid fuel assemblies to meet their cycle energy needs. Studies have been performed by Westinghouse on behalf of several customers regarding the economic benefits of this technology. Xcel Energy is proceeding with implementation of IFBA/Gad hybrid fuel assemblies in upcoming cycles of the Prairie Island Units, now that they and Westinghouse have completed the necessary licensing activities and have received USNRC approvals.