Background

The Westinghouse Next-Generation Rod Cluster Control Assembly (NG-RCCA™) has been developed to provide further performance enhancements and increased longevity of the control rod assembly. The NG-RCCA builds upon proven and reliable Enhanced-Performance Rod Cluster Control Assembly (EP-RCCA™) design, which has had a service history of more than 30 years and more than 3,000 assemblies delivered globally to a wide variety of plants designs.

The NG-RCCA design is the direct result of applying our legacy knowledge of the reactor system with innovative enhancements to provide an integrated solution fully compatible with the reactor.

Description

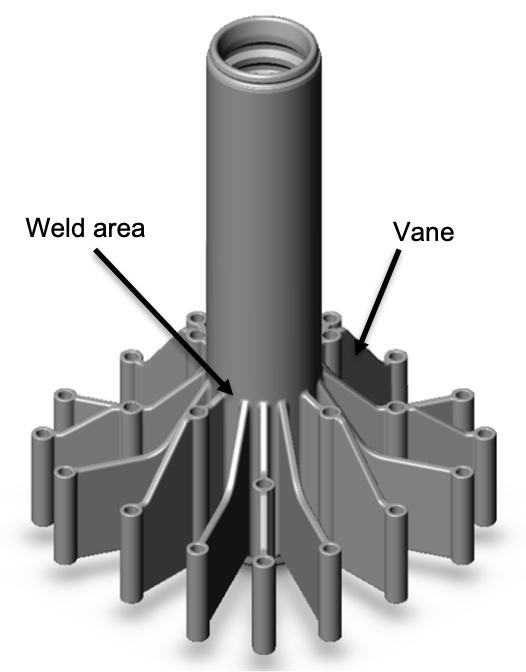

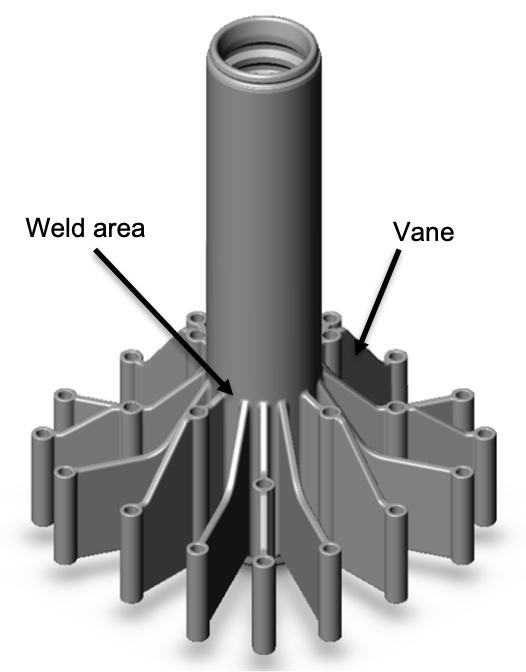

Production spider body

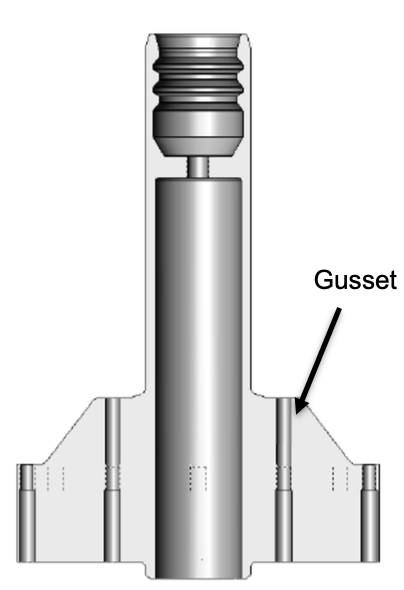

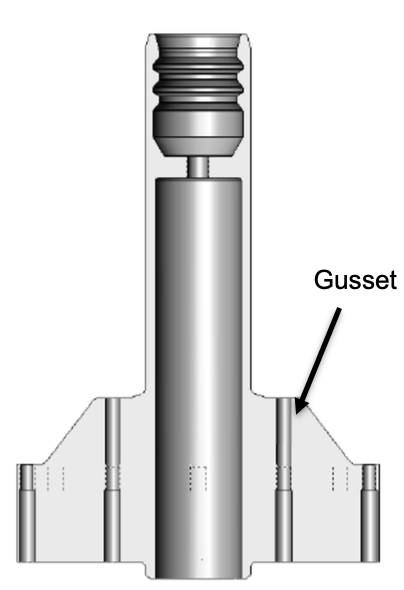

Production spider body section view

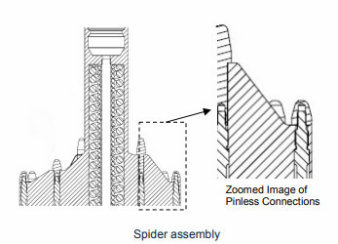

The NG-RCCA design maintains the basic RCCA configuration of a spider assembly and absorber rods that are composed of absorber material, rodlet cladding, end plugs and chrome plating. Improvements have been made to the spider, absorber rod connections and the absorber geometry to improve the overall strength and useful life of the NG-RCCAs.

Westinghouse has also incorporated a new spider design that reduces the number of welded subcomponents from 41 pieces to two pieces, held together with a single weld. This was achieved using an innovative material cutting method that provides a high degree of precision and reproducibility. The spider vanes have an enhanced gusset to increase the overall fatigue strength of the product.

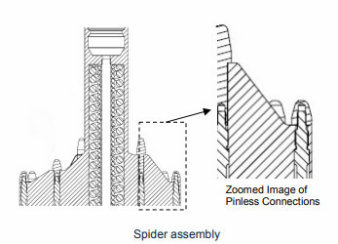

Additionally, the NG-RCCAs utilize an innovative rodlet connection design that eliminates the need for pinned connections. There are new top-end plug extensions with flexure joints to allow for opposite thread pinless connections with lock welds.

The pinless absorber rod connection to the spider further reduces the risk of a dropped absorber rodlet when compared to other RCCA pinned connection designs.

The NG-RCCA design continues to leverage the same industrial hard-chrome plating on the surface of the absorber rod cladding used in previous generations. Based upon years of successful operating performance of in-service Westinghouse RCCAs, this plating provides robust wear resistance for the RCCA rodlets and without causing excessive wear on the upper internals guide cards.

Westinghouse has also incorporated design changes to the lower absorber region geometry to further mitigate irradiation-assisted stress corrosion cracking in this region.

Benefits

The NG-RCCA offers the following benefits:

- Engineered for an extended operational service life

- Increase in fatigue margin and vane buckling load resistance, which is expected to increase component useful life

- Engineered for a lower overall drag force as compared to other RCCA designs to improve control rod drop times

- Pinless connection further reduces the possibility of a dropped rodlet

- Improved quality and manufacturability – can hold tight dimensional tolerances, especially in spider-to-rodlet connections

- Westinghouse Electric Company 1000 Westinghouse Drive Cranberry Township, PA 16066

- Minimal to no impact on operations and handling; existing guide combs and tooling remain applicable

- Designed for compatibility with existing RCCA and fuel hardware – no expected impacts on nuclear design, thermo- hydraulic design, safety analyses and technical specifications

- Seamless transition via a basic customer change 10CFR50.59 evaluation, supported by Westinghouse as applicable

Experience

Westinghouse has been delivering its EP-RCCA design since 1987. The EP-RCCAs have been used by more than 25 customers worldwide in over 70 plants. Westinghouse EP-RCCAs have a proven performance track record. Over 3,000 EP- RCCAs of a wide variety of designs (14x14, 15x15, 16x16 and 17x17) remain in operation.

Based upon the knowledge gained from many years of manufacturing control rod assemblies and from a significant collection of RCCA in reactor performance data, Westinghouse has developed the next-generation product as an evolution to its EP-RCCA design. Many of the NG-RCCA design features have been used on AP1000® plant 17x17 RCCAs and enhanced gray rod control assemblies.

Westinghouse has delivered NG-RCCAs to several utilities in the United States since 2016 for the 17x17 Westinghouse nuclear steam supply system (W-NSSS) customer base. Westinghouse is ready to support interested W-NSSS customers with purchase and delivery of NG-RCCAs.

More recently, efforts have started to analyze EP-RCCA lifetime including flexible power operations (FPO), depending on the operational needs of utilities on a plant-specific basis.