Background

The Westinghouse Advanced Nodal Code (ANC) is a highly accurate and efficient two-energy group, three-dimensional (3D) core simulator code. It uses the nodal expansion method for the nodal coupling coefficient, a group theory for pin power recovery, and the equivalence theory for homogenization.

ANC 9, the latest Westinghouse code release, employs the once-through cross-section methodology implemented in the NEXUS cross- section generation code package. The cross sections from the NEXUS system are used as input to the fast nodal solution and pin-power recovery calculation, providing accurate predictions for a wide range of conditions.

Code Descriptions

ANC 9

ANC 9 is an accurate and efficient 3D core neutronics simulator built on decades of experience in nodal simulation. The code incorporates many enhanced core physics methodologies and provides flexible input allowing the user to model a wide variety of conditions, including fuel management calculations, accident analysis and plant operational scenarios.

ANC 9 is used for nuclear core design calculations. It predicts core reactivity, assembly power, rod power, detector thimble flux and other relevant core characteristics.

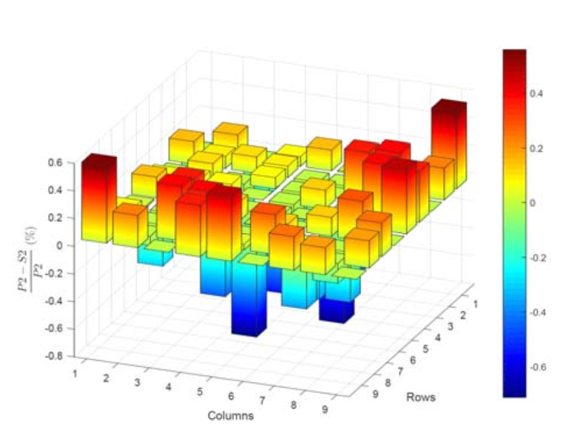

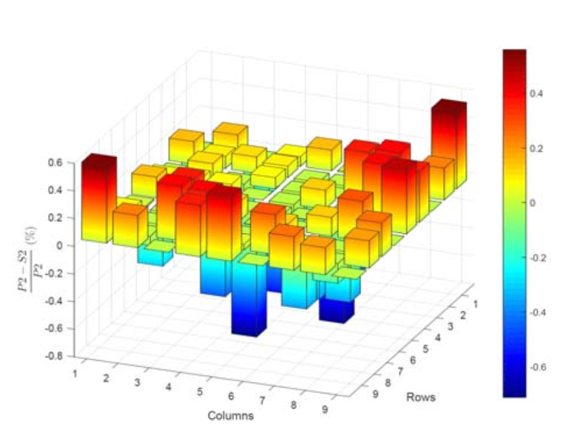

Figure 1

This figure shows the PARAGON2 predictions compared to Monte Carlo analysis for pin-power distribution.

PARAGON™

PARAGON is the licensed lattice physics code that solves the neutron and photon transport equation using 70-enegy groups and user defined geometry and material compositions. PARAGON performs the burnup depletion using the used detailed geometry and boron letdown.

NEXUS

The NEXUS code system is comprised of NEXrun, NEXpre, ALPHA, PARAGON and NEXLink codes. The NEXrun and NEXpre are used to drive the ALPHA code for various calculational branches for a desired segment of an assembly. ALPHA generates the inputs for PARAGON and runs the application. The outputs of PARAGON are then collected by NEXLink to produce the CellData (CD) files that contains the data needed by ANC. This process is driven by NEXrun, which performs the overall program automation. The CD file is used for the entire “life” of an assembly in the reactor core and for all simulation conditions.

The NEXUS/ANC code system is based on the two-step calculation approach. In the first step, performed by NEXUS, the necessary two-energy groups data are generated at the fuel assembly level. This data is used by ANC, in the second step, for core design and simulations.

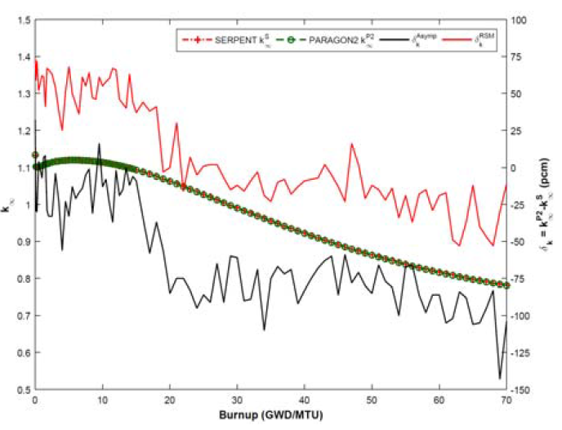

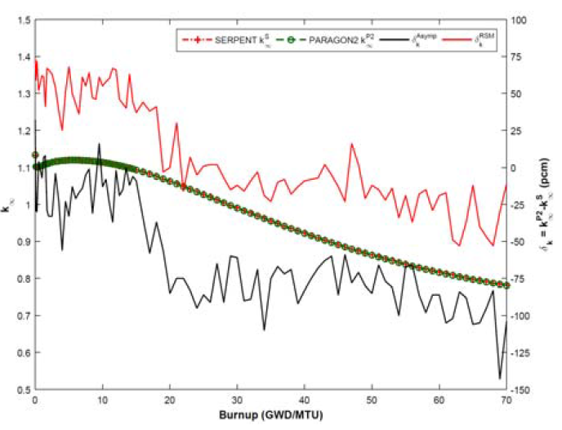

Figure 2

This figure shows the PARAGON2 predictions compared to Monte Carlo analysis for reactivity.

Benefits

NEXUS is designed to be user-friendly and easy to use by making it highly automated such that very few lines of input are needed from the user to perform the calculations.

ANC 9 capabilities include detailed tracking of core depletion parameters (actinide and fission products, pin power and burnup, fuel and component fluence), explicit modeling of spacer grids, and improved thermal hydraulic modeling. ANC 9 can model a variety of discrete burnable absorbers and has the ability to allow placement and shuffling of burnable absorbers into fresh and burned fuel.

Westinghouse Integrated Methods

ANC 9 is linked with the VIPRE-W thermal hydraulic code for use in 3-D space-time neutronics calculations as well as other various Westinghouse-developed analysis methodologies. Examples of such analysis include calculations of departure from nuclear boiling (DNBR) both for online core monitoring and for the best estimate analysis of core operation space (3DFAC), steam line break and 3-D Rod ejection analysis.

ANC 9 is the solution engine powering the BEACON™ core monitoring system. This integration allows for a broader range of operation for the BEACON core monitoring system, and full consistency between core design and monitoring applications.

Experience

PARAGON/ANC is widely used for pressurized water reactor (PWR) core analyses in more than seven countries. Westinghouse’s detailed knowledge of the fuel hardware makes the modeling in NEXUS/ANC lead to highly accurate predictions.

PARAGON2/ANC code system has accumulated several decades of developments, making it capable of simulating all PWR fuel types including all burnable absorber types (integral and discrete such as TPBAR, WABA, IFBA, Gadolinium, Erbium, etc.). PARAGON2/ANC can also be used to explore new fuel products such as accident tolerant fuel, higher enriched fuel and non-UO2 fuel types.

ANC 9 and the NEXUS code system have been qualified against measured plant data and critical experiments. Plant benchmarks include numerous plants covering all PWR types, with varying lattice and fuel types, power ratings and cycle lengths. In addition, there is a large database of comparisons of NEXUS/ANC 9 predictions to plant measurements that shows excellent agreement.

ANC, BEACON, and PARAGON are trademarks or registered trademarks of Westinghouse Electric Company LLC, its affiliates and/or its subsidiaries in the United States of America and may be registered in other countries throughout the world. All rights reserved. Unauthorized use is strictly prohibited. Other names may be trademarks of their respective owners.