Westinghouse’s latest advancement in Non-LOCA Transient Analysis Methods fulfill regulatory requirements while providing operational benefits leading to improved plant economics.

Background

Operation of a nuclear power plant requires an accurate and robust safety analysis. New regulatory requirements, advancements in fuel designs, plant upgrades supporting long-term operations and license extensions drive the need for advanced safety analysis codes and methods.

Westinghouse’s latest advancement in analytical capabilities is a statistical method to analyze non-loss-of-coolant accident (LOCA) events. These events are traditionally analyzed using deterministic bounding methods that can be overly conservative, resulting in low margins to the acceptance criteria or restrictions on plant operations. Westinghouse’s Statistical Transient Method (STM) replaces the traditional safety analysis approach for a subset of the non-LOCA events.

Description

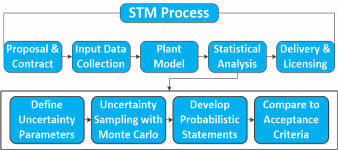

Figure 1: STM Process at a Glance

STM is a statistical method for combining uncertainties for non-LOCA safety analyses. Within the STM process, several key uncertainty contributors are combined using a non-parametric statistical method. Uncertainties are sampled in a direct “Monte Carlo”-style analysis, designed to generate a sample of the population of predicted results. Non-parametric statistical inference procedures are applied to develop probabilistic statements based on the sample, which are in turn used to show a high probability of compliance with the given criteria.

Operational Benefits

The additional margin obtained by STM for non-LOCA events can be used to improve plant economics and operation, including:

Relaxed Operational Restrictions on Safety Equipment

- Auxiliary feedwater (AFW) system performance and start times

Relaxed Operator Action Time Requirements

- Increased time to realign AFW system Loss of Normal Feedwater and Main Feedwater Line Break events

- Increased operator action time to unblock pressurizer power operated relief valves

- Increased operator action time to terminate Emergency Core Cooling System flow

Key Features

Utilizes Licensed Safety Analysis Codes

- Uses licensed versions of the LOFTRAN and RETRAN02W computer codes

- Simplifies the licensing of the method and the analysis itself

Simplified Licensing Approach

- Samples only a key subset of uncertainties and maintains conservatism in the analysis

Utilizes Licensed Statistical Methods

- Uses a mature statistical method similar to the ones already licensed as part of the Westinghouse best-estimate LOCA analysis suite

Deliverables

Westinghouse delivers a plant-specific STM report describing application of the methodology. This technical report includes the plant model description, results of the analyses performed, and a report for inclusion in the owner’s licensing submittal to the U.S. Nuclear Regulatory Commission (NRC). Westinghouse provides verification that the appropriate acceptance criteria for the event and any NRC Safety Evaluation Report requirements have been satisfied.

For a comprehensive solution, Westinghouse can provide additional resources to the utility. These include modified sections of the Final Safety Analysis Report (FSAR) incorporating the STM results and methods, and applicable technical specification markups.

Opportunities

Since plant-specific licensing is necessary upon first application, this method can be used by U.S. and international customers. Westinghouse is interested in partnering with a utility for first application licensing. If interested, please contact Westinghouse for additional information.