The Westinghouse Solution

Westinghouse is best positioned to design and deliver customized services using resins, for various applications, on nuclear sites. Resins are highly adaptable to specific customer needs.

Customer Benefits

Westinghouse develops processes and toolings using resins, in combination with the Westinghouse expertise in NDE, robotics solutions and nuclear field services experience. Each development is customized, to take into account the specified customer requirements.

Resin applications

- Non-destructive examination (replica molding)

- Decontamination or peelable protection

- Sealing (chemical protection, leak tightness)

- Protection against corrosion

- Debris retrieval

- Leak detection and permanent repair

Non-destructive examination

Resins can be used to perform replica molding, for detection and characterization of defects or for dimensional measurements. Westinghouse can deploy remote replica molding solutions in contaminated and confined environments (pipes, etc.).

Weld inspection by replica molding and microscope analysis

Decontamination or peelable protection

A resin coating can be sprayed on surfaces or equipment and is easily peeled:

- For decontamination, with a decontamination factor of up to 400 in a single coating and peeling application.

- For protection against corrosion (for example, coating applied on a transport cask before submersion underwater).

Example of decontamination application

Sealing

Resin seals can be applied on all types of surfaces and pieces to provide chemical protection and/or leak tightness.

Examples of resin sealings on horizontal and vertical elements

Protection against corrosion

Resin coatings can be used as a permanent protection against corrosion, for example for components located outdoors and/or in a saline atmosphere.

Example of the efficiency of the protection against corrosion on identical black steel plates located outdoors.

Left: rust after 1 year outdoors without protection

Right: after 1 year outdoors with sprayed resin protection

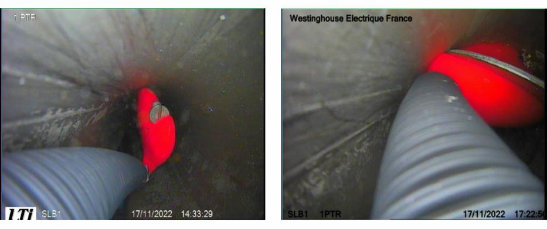

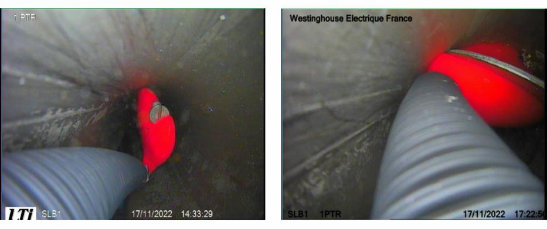

Debris retrieval

Resin injection can successfully be used for debris retrieval, where conventional debris retrieval solutions (vacuuming, gripping tools, etc.) might not be efficient (long pipes with elbows, etc.).

Debris retrieval by resin injection

Leak detection and permanent repair

Resin can be used for leak detection, as well as for permanent leak repairs, for example on the stainless steel liner welds of nuclear pools.

Left: example of leak detection in a fuel transfer canal

Right: example of leak repair on a nuclear pool liner