Hafnium-based Flux Suppressor Assembly for Reduction of Radiation-induced Embrittlement of Reactor Vessel Welds

Background

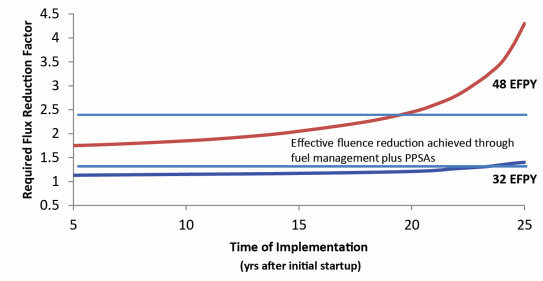

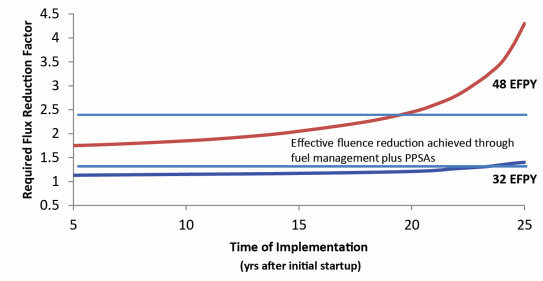

Industry studies indicate that the reactor pressure vessel may be a limiting component with respect to attaining the desired life and life extension (i.e., long-term operation/subsequent [second] license renewal [LTO/SLR]) for many nuclear power plants. The primary reactor vessel life attainment issue is concerned with the prevention of nonductile failure of the reactor vessel welds, which are subject to neutron radiation-induced embrittlement effects. For those vessels where this concern exists during their anticipated operational life, the implementation of neutron flux reduction programs can play a significant role in attaining desired reactor lifetimes. Because fluence impacts to these welds build up over time, effective fluence reduction requires implementing a program as early as possible to minimize the amount of incremental fluence reduction needed in each future cycle after program implementation (see graph).

The Westinghouse unclad peripheral power suppression assembly (PPSA) was designed specifically to address fluence reduction to reactor vessel welds in Westinghouse nuclear steam supply system (W-NSSS) reactors. The PPSA is one significant element in our overall portfolio of flux reduction methods available to reactor core designers.

The PPSA design is the direct result of applying Westinghouse knowledge of the reactor system and functional relationships between PPSAs and the system as a whole, providing an integrated solution that achieves target flux reduction goals in concert with low leakage fuel management and other fluence reduction strategies.

Description

PPSA

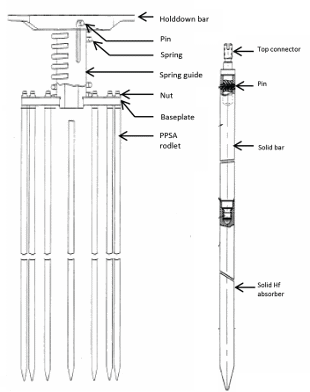

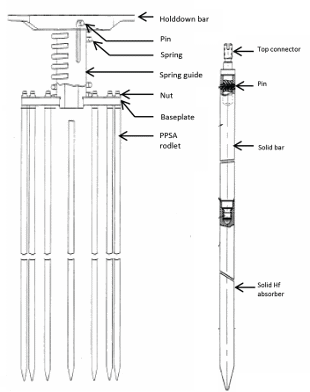

The PPSA design consists of either half- or full length hafnium rodlets that are connected to a baseplate holddown assembly. The rodlets use an unclad solid hafnium bar, an unclad solid zircaloy bar, a stainless steel connector and a stainless steel pin. The machined hafnium and zircaloy bars are joined using a threaded and circumferentially welded joint. The hafnium bar has a tapered lower end to facilitate insertion of the PPSA into thimble tubes of the target peripheral fuel assembly. The zircaloy bar is joined to the top connector by the pin. The pin is flared or crimped at each end to prevent its removal and the chances of rodlet separation. The threaded end of the connector is joined to the baseplate by the standard crimp nut used for other types of baseplate-mounted core components.

The choice of half- or full-length hafnium rodlets depends on the particular plant’s flux reduction needs as they implement PPSAs into their operating cycles.

Benefits

The Westinghouse unclad PPSA offers the following benefits:

Designed to support fluence reduction goals for critical reactor vessel welds as customers address the U.S. Nuclear Regulatory Commission amended rule on pressurized thermal shock or similar requirements in other countries.

Simple design that performs its power suppression role over a target 15-year design lifetime.

Unclad design permits a larger mass of hafnium to be incorporated into the PPSA, with a larger radius and surface area than cladded designs, thus improving the power suppression capability of the PPSA.

Can be shuffled among targeted peripheral core locations to minimize depletion gradients while providing required reactivity holddown.

Field data collected to date has demonstrated that the Westinghouse PPSAs experience little to no erosion in the reactor coolant environment. Also, customer reactor coolant system chemistry analyses performed to date have shown no detectable concentrations of hafnium in PPSA resident reactor operating cycles.

Designed to work singularly or in concert with low leakage fuel management strategies as well as with other more aggressive flux reduction products such as shielding fuel assemblies.

Experience

Westinghouse has been delivering cladded PPSA designs since the late 1980s to 14x14 and 15x15 W-NSSS reactors where fuel management initiatives alone were insufficient to achieve the target reduction goals. The unclad PPSA design has been delivered since 1994 and has been used in 15x15 and 17x17 W-NSSS reactors.

PPSAs have been included as important elements in flux reduction programs for several customers. There is currently renewed interest in deployment of PPSAs in support of customers’ LTO/SLR goals.

Based upon the knowledge and experience we gained from many years of manufacturing and analyzing PPSAs and from our collection of PPSA performance data, Westinghouse is well qualified to assist customers in formulating a fluence reduction program that is tailored to individual needs.

Sample flux reduction program