Background

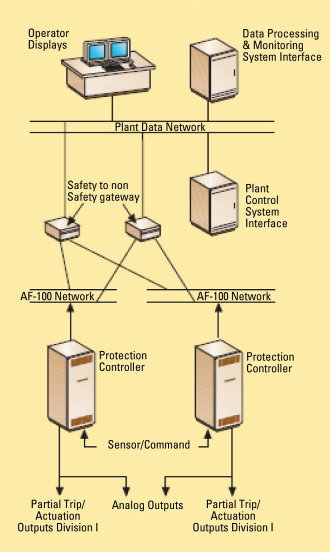

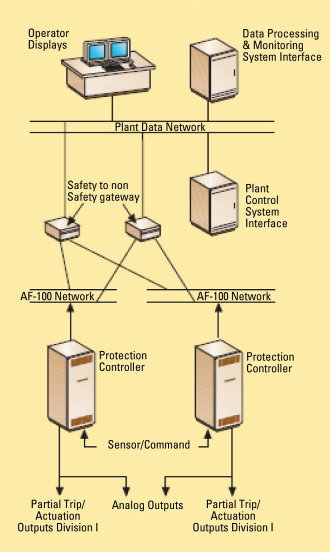

The plant protection system monitors plant temperatures, pressures, levels, flows and nuclear instrumentation system outputs. If these parameters exceed plant safety limits, the system issues “partial reactor trip” and “engineered safeguards” commands. The plant protection system sends isolated analog output signals to the plant control system, the data processing and monitoring system, and the main control board. It also provides alarm outputs to the plant annunciator system. The plant protection system can be supplied with an interface to the data processing and monitoring system, or implemented as a standalone upgrade to the existing plant system. When supplied with an interface, a phased approach permits small stand-alone upgrades to be eventually integrated into a total plant information network.

Description

Plant protection system architecture

Protection Logic System

The protection logic system receives partial reactor trip and engineered safeguards features (ESFs) actuation commands from the plant protection system and the nuclear instrumentation system. The protection logic system provides alarm and status outputs to the plant annunciator system, and the data processing and monitoring system. The protection logic system comprises two or four redundant trains of actuation. Each train receives partial reactor trip and ESF actuation commands from each of the plant protection and nuclear instrumentation channels, and from the reactor coolant pump sensors. If the coincidence logic is satisfied, the system provides reactor trip and ESF actuation command outputs. The system also receives inputs from the control board to permit the operator to block, reset or manually actuate certain functions. The plant protection system features a rack-mounted, flat panel display. This maintenance panel is used to change system tunable parameters, trend process parameters, review system status and initiate diagnostic tests.

Diverse Actuation System

The diverse actuation system (DAS) provides plant protection in the event of a common-mode failure of the reactor protection system. The DAS uses hardware and software that is different from the reactor protection system.

The DAS has two or three redundant channels of measurement. The DAS monitors a select set of input signals and provides reactor trip and a reduced set ESF function.

In addition, the DAS provides a diverse monitoring system that monitors critical plant parameters. Diverse monitoring can be provided by analog outputs or by a control-board-mounted display.

Benefits

The plant protection system provides the following benefits:

- Safety highway that can be expanded to a wide range of applications

- Testing capability that reduces calibration time, labor hours and overall plant downtime

- Built-in detection circuits and software that identify failures