Background

The WESDYNE® INTERNATIONAL team has proven its capability to solve the most complex and urgent inspection challenges in the nuclear industry in a safe and efficient manner.

We provide rapid response inspection services for power plant owners globally that experience emerging issues requiring immediate nondestructive engineering (NDE) attention.

Description

One of WesDyne’s experts at work

Local support locations

Our proven capability to deploy NDE expertise, typically within 24 hours, helps our customers significantly shorten the critical path.

Our exclusive and 24/7 capable in-house one-stop-shop of design, engineering, procedure development plus probe and robotic manufacturing enables us to deliver complete NDE solutions to the site in a very short time.

Benefits

The WESDYNE team provides integrated inspection, repair and engineering support to solve customer issues rapidly.

We do this by implementing customized NDE solutions using our pool of more than 90 qualified inspection systems globally and 80 individuals qualified by 13 or more regulators supported by Westinghouse’s local presence in over 19 countries.

Experiences

Our recent experiences in emergent support include:

- Unplanned baffle former bolt inspection completed 11 days after initial call (standard is six months)

- Unplanned in-vessel replica inspection completed on-site five days after initial call (standard is three months)

- Unplanned qualified inspection of control rod shafts 14 days after initial call (standard is six months)

- Development and qualification of new tooling for boiler spine inspection in less than six months (standard is three years)

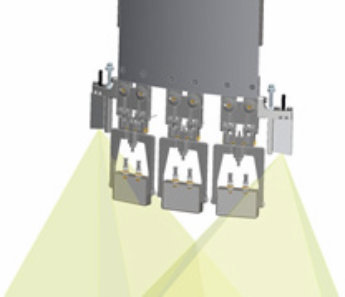

Probe head for 8 mm thick gap for boiler spine inspection CAD design and Actual probe head used