The Westinghouse Solution

Westinghouse operates a state-of-the-art service center to perform tooling refurbishments to assist utilities with tooling maintenance. This service center is staffed with experienced full-time tooling engineers and technicians and has the equipment and mock-ups required to perform proper maintenance and functionality checks to maintain reliability during refueling outages.

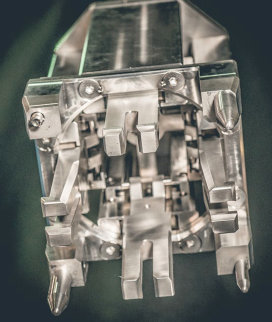

Much of the tooling and equipment used to perform refueling activities was supplied as original plant equipment or have been in use for many years. They have worn or loose parts or have experienced damage over the many years of usage. Failure to properly maintain this tooling can lead to costly critical path delays or worse yet, be a source of foreign material into critical areas of the reactor. For this reason, it is imperative for these tools to be properly maintained with applicable upgrades incorporated.

Description

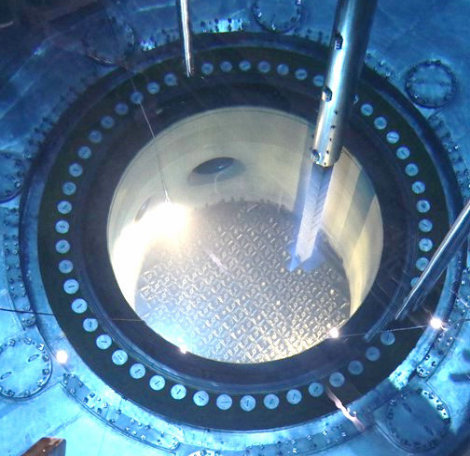

The Westinghouse Waltz Mill Service Center (WMSC) is a licensed, radiologically controlled facility where tooling can be assembled, operated, disassembled, repaired, functionally tested, and load tested to assure the tooling is ready to be used at a nuclear power plant. This WMSC is equipped to refurbish specialized tooling typically utilized during refuel activities:

- Machine Shop/Welding

- Tooling can be fabricated/modified onsite and quickly tested reducing turnaround time for repairs

- Decontamination

- Capability to decontaminate all PWR and BWR Tooling sizes.

- Overhead Cranes

- Hook height to support assembly and operation of tools.

- Equipment Testing

- Functional tests performed with actual components and mock-ups.

- Load Testing per tooling requirements

- Water Submersion Testing

Customer Benefits

The advanced facilities of the WMSC allows for cost effective inspection, repair, modifications/ upgrades, and storage of contaminated tooling between outages.

Benefits of using the WMSC include:

An Experienced Team of engineers and technicians will inspect, refurbish, upgrade, and functionally test each and every tool

A State-of-the-Art Facility that houses all of the tooling, equipment, and mock-ups to decontaminate, disassemble, modify, assemble, and test the tooling prior to return shipment

An Established Organization that embraces the nuclear culture utilizing established procedures and Human Performance tools throughout the refurbishment process.

Reactor Services Customer Tooling Refurbishment

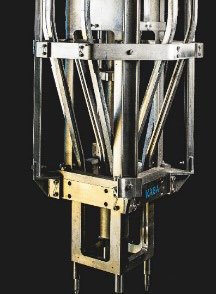

Typical Refuel Tooling Refurbished

- Long Handled Tools

- Burnable Poison Rod Assembly Handling Tool

- Control Element Assembly Extension Shaft Coupling/Uncoupling Tool (SCOUT)

- Control Element Assembly Handling Tool

- Control Rod Drive Shaft Latching & Unlatching Tool

- Control Rod Drive Shaft Button Measurement Tool

- Fluexureless Insert Handling Tool

- Irradiated Sample Handling Tool

- Rod Cluster Control Assembly Change Tool

- Spent Fuel Handling Tool

- Thimble Plug Handling Tool

- Wet Annular Burnable Absorber Change Tool

- Reactor Vessel Stud Tensioning Equipment

- Tensioners

- Pumping Units

- Electric Pumping Systems (EPN Pump)

- Self-Contained Tensioners

- Miscellaneous Tooling

- New Fuel Handling Tool

- Stud Hole Plugs

- Stud Hole Cleaner

- Stud Cleaner

- Stud Cans

- Stud Turnout Tooling

- Cavity Seal

- Polar Crane Load Cell Calibration & Supply

Deliverables

Westinghouse delivers a complete tool refurbishment which includes a detailed report documenting the work performed, the anomalies found, and any repairs performed for each specific tool refurbished.

Westinghouse can include security inspection and sealing of tooling and boxes before being shipped. This effort is provided by G4S and saves the cost of site security members traveling to Westinghouse to perform this inspection.

Westinghouse can also provide LSA shipping boxes to transfer tooling to/from utility sites if needed.

Experience

Westinghouse has been designing and maintaining refuel tooling and equipment for over 50 years. Our Customer Tooling personnel are experienced in both the use as well as the maintenance of each tool and familiar with typical problems each has experienced. This allows for a thorough inspection of the as-found condition of the tool with increased attention to those problematic areas. When issues are found, they can be quickly dispositioned with support from our tooling design group.