Background

The Westinghouse Double Encapsulated Secondary Source Assemblies (SSAs) were developed to provide an adequate source of neutrons for reload core fuel movement reactivity monitoring and subsequent cycle startups while further protecting the source material from erosion to the primary coolant system. The double encapsulated SSA design is the direct result of Westinghouse applying knowledge learned from over 4500 reactor-years of operational performance experience of the previous single encapsulated SSA design.

Since the first commercial deployment of pressurized reactors in the early 1960’s until about 1992, Westinghouse had supplied its reactor customers with secondary sources of a single encapsulated design. Originally, the SSAs rods were unpressurized. In 1973, Westinghouse improved the SSA design to include rod pre-pressurization to preclude creep collapse of the cladding. The pre-pressurization also improves the internal heat transfer associated with the SSA rods.

Performance of the single encapsulated design is predominately good. However, there were a few field instances of anomalous behavior of SSA rods where antimony was detected in the reactor coolant system. Westinghouse investigations into these few events led to the development and deployment of the double encapsulated SSA design.

Description

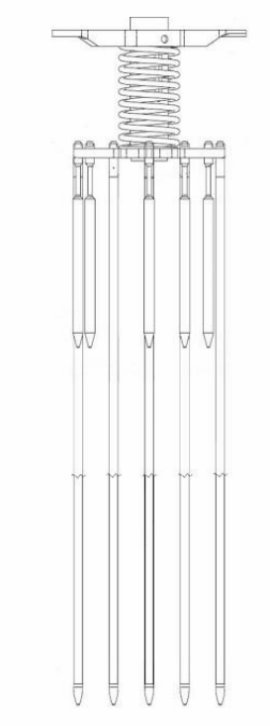

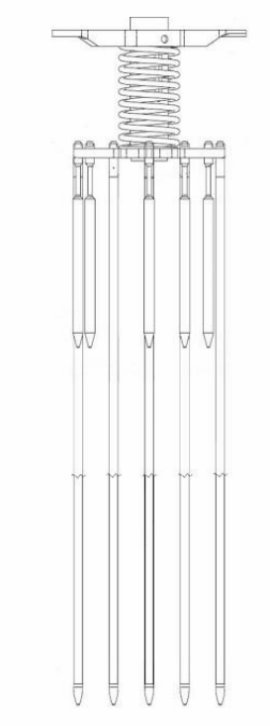

The Secondary Source Assemblies are composed of source rods, which contain antimony / beryllium (Sb / Be) pellets, which are then attached to either a base plate or a spider hub. The antimony / beryllium pellets start out non-radioactive, but transform into neutron producing source material during the first cycle of core irradiation (antimony becomes radioactive in the reactor and its strong gamma emissions [1.7 MeV for 124Sb] interact with beryllium-9 by an (γ,n) reaction thus generating photo-neutrons).

The external dimensions of the source rods are sized so that they properly fit into host fuel assembly thimble tubes.

The materials used for the SSA rods are:

- Antimony and Beryllium homogeneously mixed powders which are compacted into pellets

- Stainless Steel inner capsule, outer cladding and end plugs

- Helium fill gas for pre-pressurization of inner capsule and outer rod.

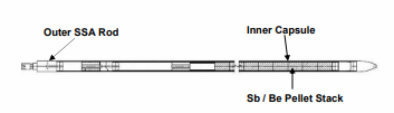

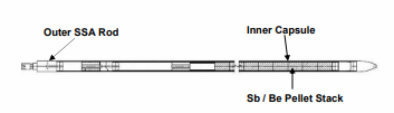

Externally, the double encapsulated Secondary Source Assembly design is dimensionally compatible with the earlier single encapsulated design. Internally, however, the double encapsulated design contains the Sb / Be pellets in an inner sealed and pre-pressurized capsule which is then positioned into the rod outer cladding. The axial positioning of the pellet stack is restrained by a pellet stack retention device. The source rod is also pre-pressurized after the lower and upper end plugs are welded in place.

Double Encapsulated Secondary Source Rod

To accommodate the inner capsule design change, the source pellet diameter is reduced while maintaining adequate neutron generation source strength to satisfy technical specification requirements.

Benefits

Secondary Source Assembly

The benefits of the Westinghouse Double Encapsulated Secondary Source Assembly design are:

- Adequate neutron source strength for reload core fuel movement reactivity monitoring and subsequent core startups

- Improved barriers to source material erosion so as to further reduce the possibility of antimony leakage to the reactor coolant system

- Excellent SSA corrosion resistance during reactor operation

- Proven long lifetime operation

- Pre-pressurized inner capsule and outer rod to preclude cladding creep collapse

Experience

Westinghouse had delivered SSAs of the single encapsulated design since the 1960’s to over 60 domestic and foreign plants and had accumulated more than 4500 reactor-years of operational performance experience. Some Westinghouse SSAs have operated for up to 15 cycles without any reported issues.

Westinghouse has been delivering the Double Encapsulated Secondary Source Assembly design since 1992 and has experienced excellent performance with the improved SSA design. Westinghouse also has over five decades of experience with designing, modeling and analyzing SSAs in reactor cores.