Background

The TracWorks® fuel data management system is a source of comprehensive, and integrated fuel and component-related information for a nuclear plant’s operators, engineers and administrators.

The TracWorks system provides life-cycle tracking, data management and reporting for all fuel assemblies or bundles and components for both pressurized water reactor (PWR) and boiling water reactor (BWR) units. The TracWorks system can eliminate the need for each of a plant’s organizations to individually manage the various fuel assembly data sets as separate entities and then integrate the various pieces by hand for individual needs. TracWorks usage provides unified and consistent information with common data sources, histories and pedigrees, reducing the potential for inconsistencies and errors.

Description

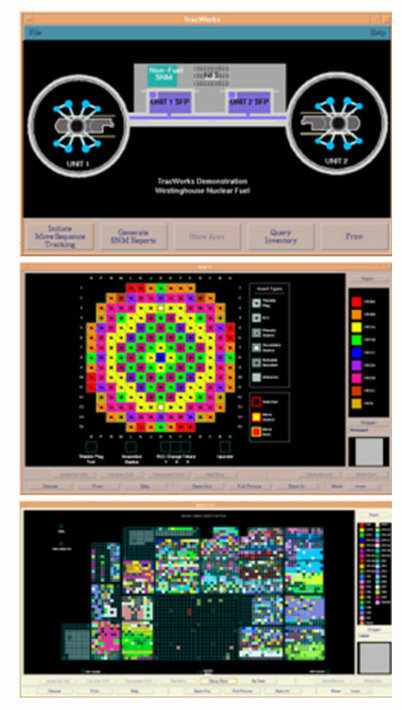

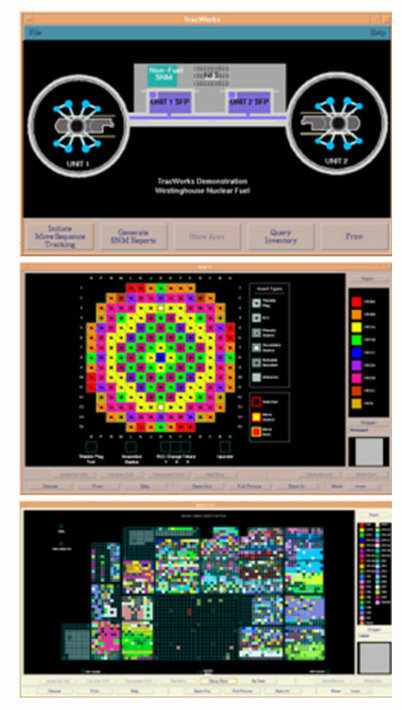

TRACWORKS provides graphical displays of fuel storage throughout the plant

The TracWorks software streamlines tracking, data management and regulatory reporting for the entire life cycle of fuel assemblies/bundles and core components. It collects, maintains and provides information for:

- Assembly/bundle and component locations and movements during the refueling process and operation

- Assembly/bundle burnup and isotopic inventory (both in-core and out-of-core)

- Fuel rod burnup and isotopics for fuel that has been removed from its original assembly/bundle

- Fuel assembly/bundle and component inspection results

- Manufacturing data

Available services include continuing hardware procurement services support of the initial historical data load, network management services upgrades and maintenance.

TracWorks Modules

The TracWorks system has seven modules:

Baseline Modules

- Inventory management – provides inventory management for assembly/bundle and core components from delivery to final disposal

- Fuel properties tracking – provides up-to-date information about individual fuel assemblies/bundles, including isotopic histories and burnup histories

- Reporting – creates documents for regulatory requirements with options for both U.S. Nuclear Regulatory Commission (NRC) and International Atomic Energy Agency reports

Additional Modules

- Fuel-movement planning and move-sequence tracking

- Real-time movement monitoring

- Decay heat monitoring including time to boil calculations

- Core component lifetime monitoring

Benefits

The TracWorks system provides a high level of protection against costly, time-consuming errors in assembly/bundle selection and placement. It can also help reduce the time needed to perform both routine and specialized plant operating, maintenance and administrative activities.

Key benefits include:

- Reduces the probability of fuel-selection errors during refueling (e.g., selecting the wrong assembly/bundle or attempting to place a spent assembly/bundle in an occupied storage location), thereby reducing the time required to resolve errors and reducing the possibility of U.S. NRC involvement

- Reduces the effort in generating and checking the fuel shuffle by several man-weeks (versus preparing the shuffle by hand); and the shuffle itself can be optimized to potentially minimize critical-path refueling time

- Significantly reduces the effort required to generate required SNM reports for the U.S. NRC

- Reduces the administrative controls required, even for very complex burnup credit racks, by automating the controls and thereby reducing required effort, improving reliability and providing support for whatever controls might be required to account for absorber degradation

- Increases the availability of the fuel rod and fuel assembly/bundle manufacturing data, significantly reducing the time required on-site for an audit of the manufacturing plant

- Provide a single, universally available controlled access source of the various fuel assembly data

Complimentary Systems

The TracWorks system can be integrated with the other Westinghouse systems including:

- ALPHA/PHOENIX/ANCTM (APA) core design system

- BEACONTM core monitoring system

- SHUFFLEWORKS®

- CASKWORKS®

- PoolWorksTM

These capabilities are complementary to TracWorks, so these links enhance the user experience for those who have purchased one or more of these products.

Experience

The TracWorks system is used at over 52 nuclear power plants globally, including the Westinghouse AP1000® plants. TracWorks has been the system of choice for fuel and component tracking and material reporting for more than 20 years.

ANC, BEACON, CASKWORKS, PoolWorks, SHUFFLEWORKS and TracWorks are trademarks or registered trademarks of Westinghouse Electric Company LLC, its affiliates and/or its subsidiaries in the United States of America and may be registered in other countries throughout the world. All rights reserved. Unauthorized use is strictly prohibited. Other names may be trademarks of their respective owners.