Background

The lower canopy seal Weld is a weld between the reactor vessel head control rod drive mechanism (CRDM) latch housing and the reactor vessel head (RVH) penetration adapter. This weld has a tendency to develop cracks as a result of stress corrosion cracking (SCC) and/or original weld defects. These cracks spread through the walls and create leakage.

Small leaks in pressurized water reactor (PWR) head penetrations can prevent a nuclear power plant from returning to power and cause expensive delays until a fix is devised. An increasing number of plants are reporting primary coolant leaks in the field-welded canopy seal area.

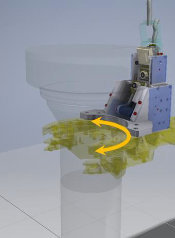

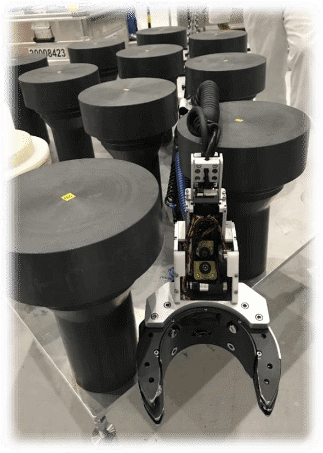

Figure 1 – Clamp and its inspection device docked on a penetration

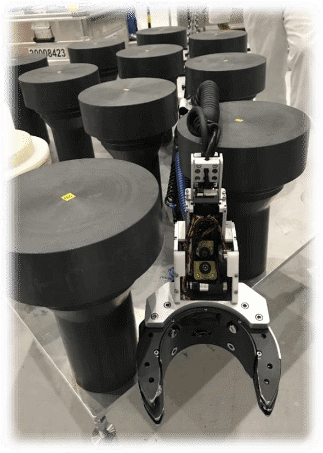

Figure 2 – Brushing tool

Technology Description

To detect these kinds of leaks, Westinghouse has developed a visual inspection system, which includes:

- A visual inspection device

The visual inspection device includes two cameras and lighting blocks and is installed on a clamp that is docked to the CRDM penetration. The clamp and thus the visual inspection device can rotate around the penetration in order to perform a 360° visual inspection of the canopy weld (Figure 1). The two cameras on the visual inspection device are mobile in three axes to obtain the best view angle of the canopy weld.

A brushing tool, installed on the clamp (Figure 2), is also available to brush any obstructions or deposit which could prevent a complete visual inspection of the weld.

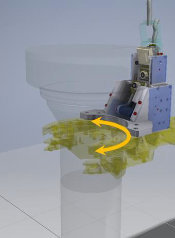

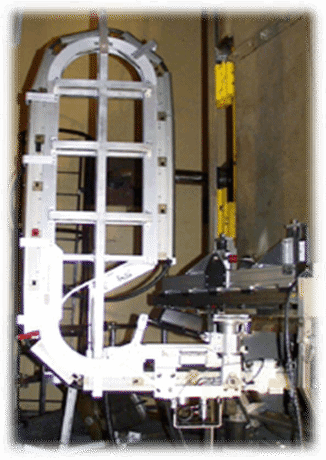

The tool carrier, designed to bring the clamp and its visual inspection device to the CRDM penetration, navigates through the tight space between the penetrations (Figure 3). The tool carrier is clamped on the side of the RVH (Figure 4).

Benefits

The main advantages of Westinghouse’s visual inspection system are:

- Compact design of the inspection system allowing all penetrations to be inspected

- Visual inspection device allowing 360° video recordings of the canopy weld

- Brushing tool allowing complete visual inspection of the weld

- No human intervention directly over the RPVH

- Low radiation exposure for technicians and low overall exposure dose

Experience

The inspection system has successfully been used at customer sites by Westinghouse field services teams for more than 20 years.

Figure 3 – Clamp and its inspection device going through penetration mockups

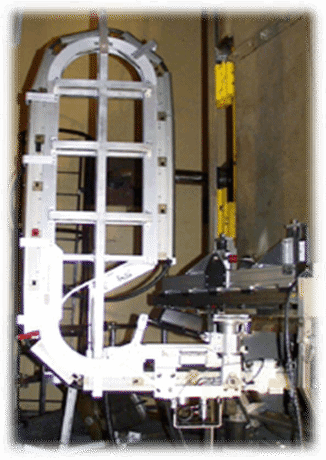

Figure 4 – Tool carrier outside of the RVH