Background

The Robust Westinghouse Fuel Assembly (RWFA) design has rapidly become the Westinghouse standard fuel product for the VVER-1000 units in Ukraine. The RWFA design is

an evolution of Westinghouse ́s previous VVER-1000 fuel design, WFA, which was first introduced as Lead Test Assemblies in South Ukraine Unit 3 in 2005.

Mechanical features and stronger materials were introduced in RWFA to avoid damage from mechanical interference during the core loading and unloading. The RWFA product has demonstrated excellent performance and reliability. Moreover, it is designed for the conditions following planned power uprates as well as load follow operation.

Westinghouse is also introducing a modified RFWA design for the Temelín nuclear power plant in the Czech Republic. The new design, which will be demonstrated in a Lead Test Assembly (LTA) program, will include fewer spacer grids for the assembly to be compatible with non-Westinghouse fuel, and material upgrades to further benefit the fuel economy and performance.

Description and benefits

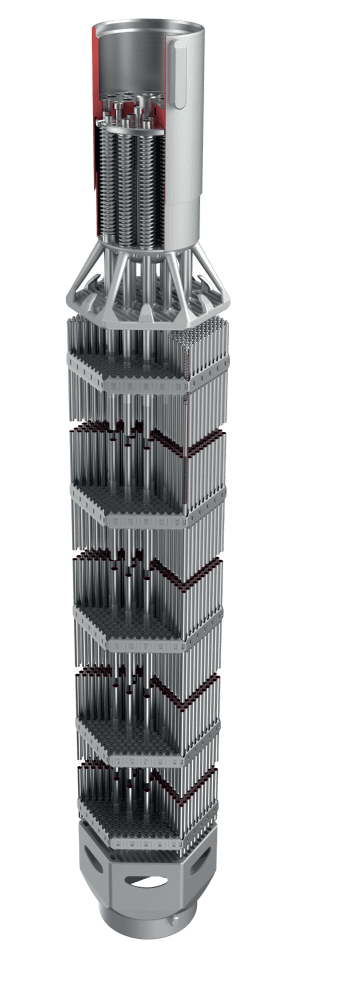

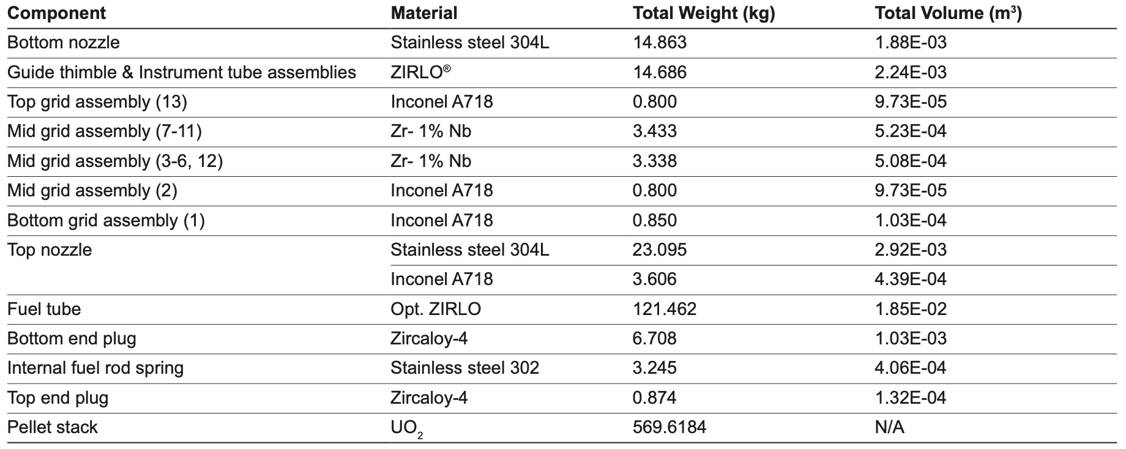

The VVER-1000 RWFA design is shown in the illustration to the right, some key features are:

- Bottom Nozzle

- includes a taper on the bottom of all six faces and increased edge breaks, which will minimize the mechanical interaction during the core loading.

- Top Nozzle

- this is removable to enable fuel rod repair and equipped with deflectors to ease the core loading.

- Grids

- the mechanical strength has been increased through use of Inconel 718 for all 16 grids, inner straps in all directions and more robust outer straps.

- Fuel Rods

- totally 312 with ZIRLO®cladding tubes. Long, solid bottom end plugs for debris fretting protection.

- Skeleton

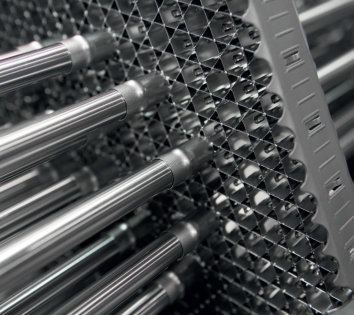

- thimble tubes and instrumentation tube in ZIRLO®, these are double-bulged to the sleeves of the grids (see photo on the next page) resulting in a very robust structure.

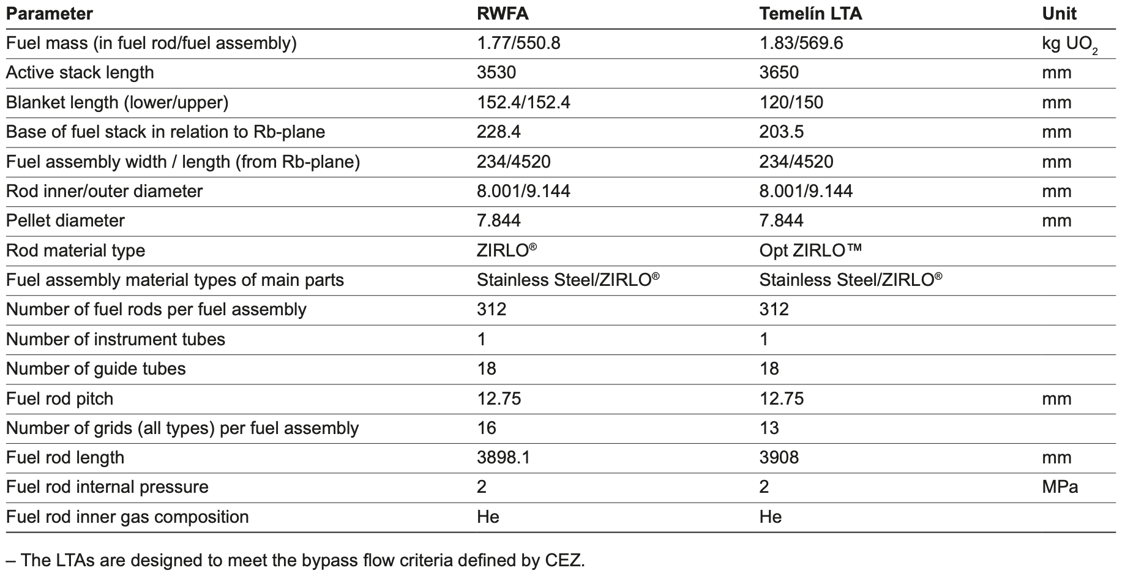

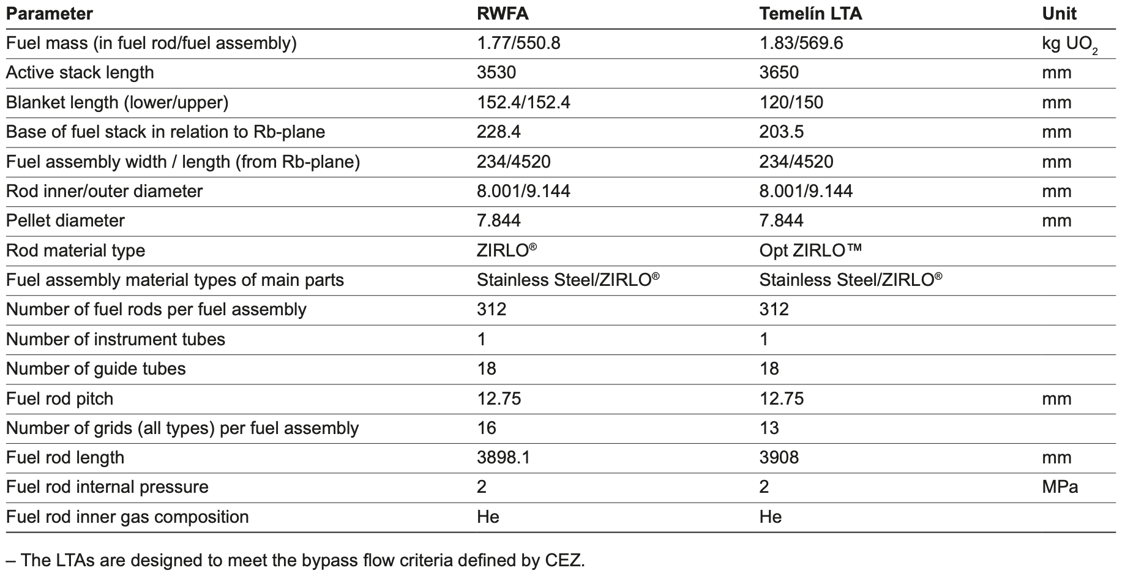

Key data for the RWFA design and the Temelín LTA design are listed in the next section.

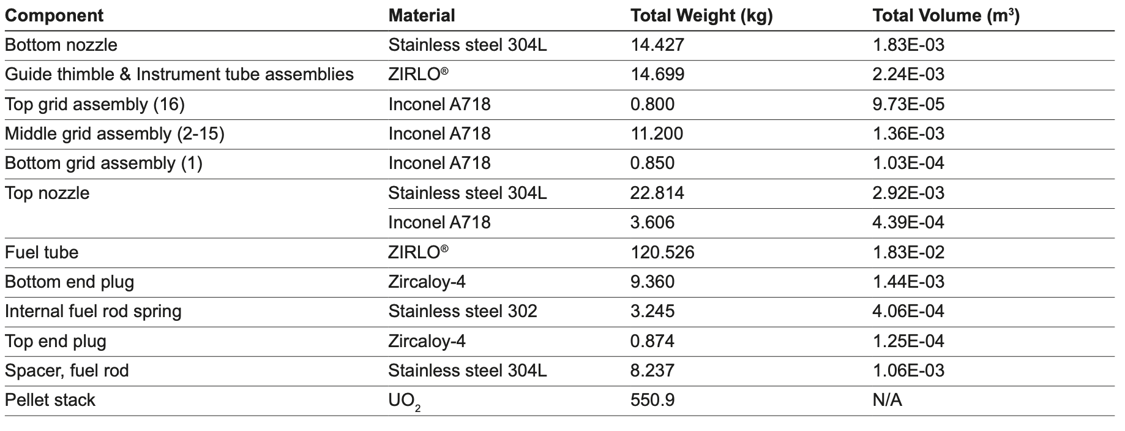

Technical Data

Experience

As of 2018, the Westinghouse RWFA product has been delivered to six different VVER-1000 units in Ukraine, with a total number of delivered fuel assemblies (including WFA) exceeding 1000 by the end of the year. The inspections and Post Irradiation Examinations (PIEs) of the fuel show excellent performance of both the WFA and the RWFA designs. The fuel assembly distortion has been very limited, with less than 10 mm bow

and twist, and the Temelín LTAs are expected to perform within this range as well.

With the mechanical changes introduced in RWFA no damages during core loading or unloading have been recorded.

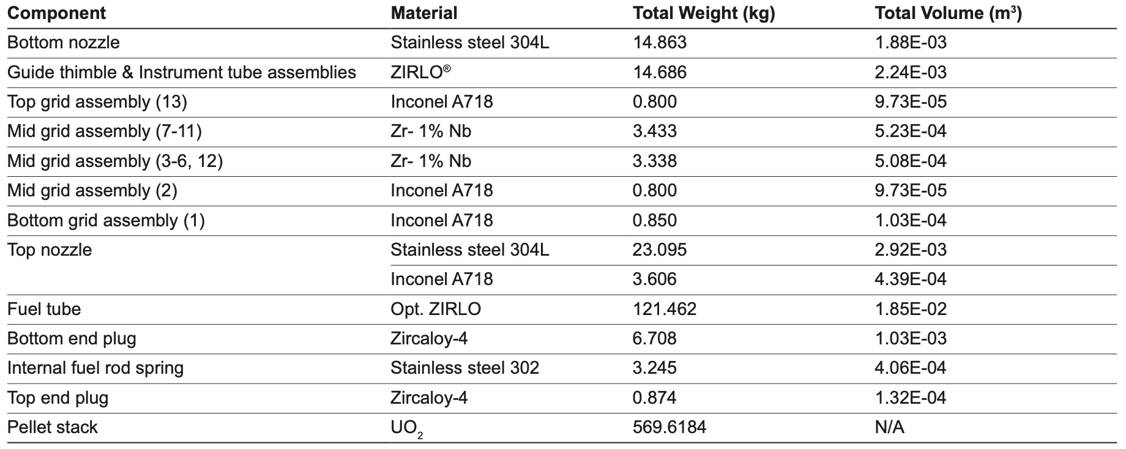

RWFA design

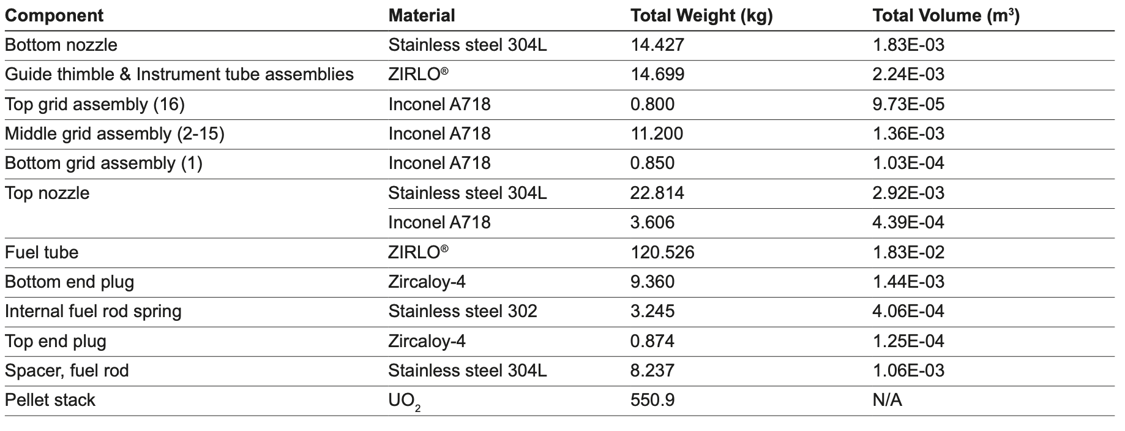

Temelín Lead Test Assembly design

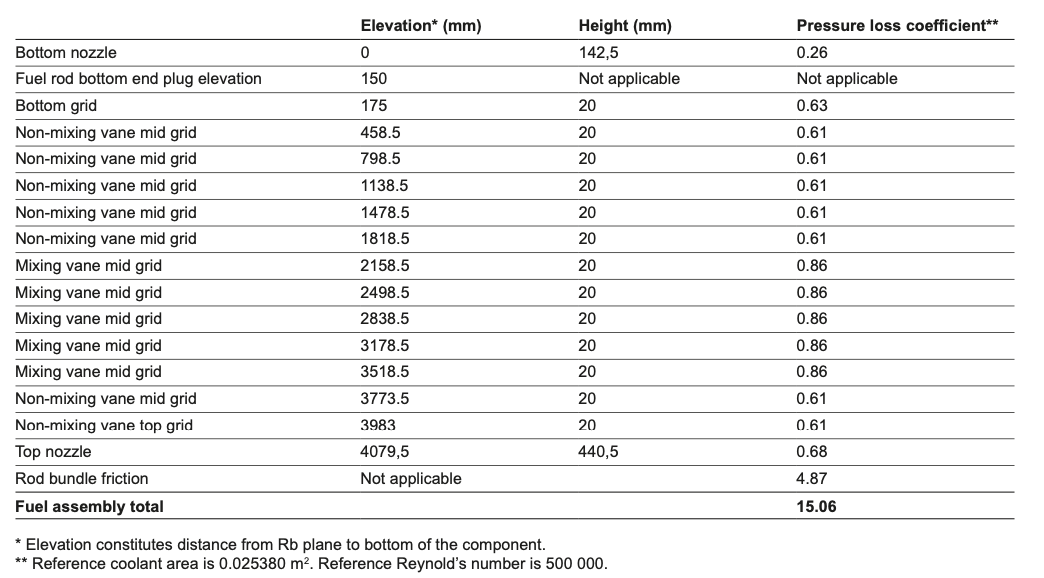

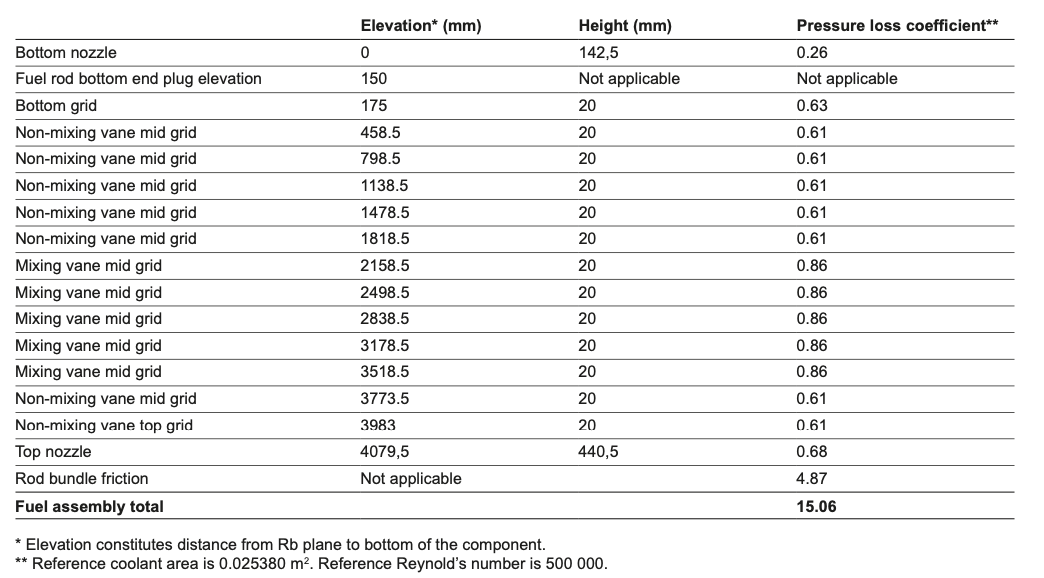

Pressure loss coefficients vs components elevation

Fuel assembly lateral stiffness

The minimum lateral stiffness of the Temelin LTA fuel assembly for a 25.4 mm displacement is 48.9 N/mm (BOL) and 26.6 N/mm (EOL) at room temperature in air.

BOL and EOL dynamic grid stiffness and strength

The table below provides grid dynamic strength and stiffness at BOL at elevated temperature in air. EOL grid stiffness and strength are bounded by the BOL values.

| Stiffness |

4712 kN/m |

| Dynamic Crush Strength |

7139 N |

Top nozzle as-built spring characteristics and fuel assembly growth

The table below presents top nozzle holddown force and stiffness at BOL Hot Full Power conditions. The fuel assembly growth is 5 mm at 60 MWd/kgU.

| Top nozzle hold down force (nominal) |

7402 N |

| Top Nozzle hold down spring stiffness (nominal) |

195 N/mm |