Background

Many nuclear utilities installed their post-accident monitoring instrumentation using technology from the late 1970s and early 1980s. In this rapidly changing technological environment, component obsolescence and ever increasing operations and maintenance (O&M) costs are a growing concern. To address this, Westinghouse is pleased to offer a modernized PAMS using its common qualified (Common Q™) platform.

Description

The Common Q™ platform is a single common platform designed with modular components that can be combined to solve most utility needs for Class 1E applications, including component replacements and complete system upgrades.

The Common Q™ PAMS includes the following functions:

- Core exit thermocouple monitoring

- Reactor vessel level monitoring

- Subcooled margin monitoring

- Regulatory Guide 1.97 monitoring

By definition, Common Q™ is Class 1E; therefore, all of its building blocks are Class 1E. The Common Q™ platform consists of the following major building blocks that can be used to design a modernized PAMS:

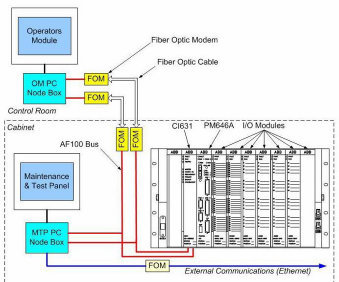

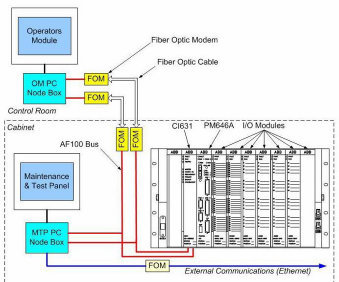

- ABB Advant® Controller 160 (AC160) with PM646A processor module input and output cards

- Modular power supply assembly

- Flat panel display system (for operator’s module and maintenance/test panel)

- Advant® fieldbus (AF100) communication

The Common Q™ PAMS includes built-in self-diagnostic and automated test features designed to reduce manual surveillance test labor. The system is also equipped with a variety of communications interfaces including UDP and isolated TCP/IP links designed to provide an interface to the unit’s existing plant computer.

Typical Common Q™ PAMS Architecture

Benefits

Reliability

Common Q™ has a proven history of reliability and availability.

- Availability of System 99.9999%

- Mean Time between Failures (MTBF) of AC160 > 70 years

- Mean Time to Repair (MTTR) Components < 6 hours

Verification and Validation

The Westinghouse PAMS is qualified for Class 1E nuclear safety-related applications. This system is also in compliance with the U.S. Nuclear Regulatory Commission (NRC) Regulatory Guide 1.97. A verification and validation program, approved by the NRC, is used for Common Q™ development activities. Westinghouse customers can directly reference the Common Q™ Safety Evaluation Report for any of their licensing submittals to ease the licensing process.

Obsolescence Management

Westinghouse has structured a long-term obsolescence management program as part of its Common Q™ solution. The Westinghouse Common Q™ design philosophy is focused on engineering that supports standard designs and reusability, thereby reducing overall O&M lifecycle costs. Westinghouse is employing this design philosophy for all new nuclear power plants and operating power plants that it supports around the world.

The Westinghouse Common Q™ obsolescence support plan is designed to provide configuration control for investment protection and management of the long-term obsolescence support goal. The elements of this plan are:

- Full production (for new systems) for an extended period without requalification cost to the utility

- Spare parts production for an additional period without requalification

- Westinghouse-pooled inventory spares stocking, as required, based upon usage history and expected plant life

Common Q™ AC160 Processor

Experience

Westinghouse’s Common Q™ Platform has one of the largest safety-related installed bases in nuclear power plants in the world including:

- 1,300+ Cabinets

- 2,500+ AC160 rack

- 800+ Flat Panel Displays

- 4,000+ Controllers

As the technology of choice for all new plant safety systems and operating plant safety system upgrades, Westinghouse is committed to long term support of the Common Q™ product line with contractual support commitments to 2055 and beyond.

Common Q™ PAMS (shown with factory test carts)

O&M Savings

The Westinghouse Common Q™ PAMS is designed to reduce Operating and Maintenance costs through technology, high reliability, and integration.

- The online surveillance and automated test features have been reviewed and approved by the NRC as described in the Common Q™ safety evaluation report. This provides the potential to extend the interval of calibration checks and manual tests.

- As a fully digital system, the AC160 does not require ongoing calibration like legacy analog systems.

- Common Q™ technology promotes synergistic data integration with other I&C systems such as a Plant Computer, other Common Q™ systems, or an Ovation™ control system.

Common Q is a trademark or registered trademark of Westinghouse Electric Company LLC, its affiliates and/or its subsidiaries in the United States of America and may be registered in other countries throughout the world. All rights reserved. Unauthorized use is strictly prohibited. Other names may be trademarks of their respective owners.

Advant is a registered trademark of ABB Process Automation Corporation. Other names may be trademarks of their respective owners.