Progress and Remaining Milestones in Support of U.S. Energy Security and Climate Goals

Background and Benefits

In 2012, U.S. Congress issued a directive for the development of Accident Tolerant Fuel (ATF) in response to the unprecedented tsunami in Japan that led to complications at the Fukushima Daiichi nuclear plant. ATF products are designed to enhance performance and increase safety under accident conditions. Westinghouse leads one of three industry teams supporting this directive. Congressional funding awarded by the U.S. Department of Energy (DOE) has enabled progress through Phase 2C (Development). The program was later expanded to include higher enrichment (LEU+) and higher burnup for additional economic benefits to nuclear plants. Future awards by the U.S. DOE to see this program through to completion is dependent on continued support from Congress.

Westinghouse EnCore ATF Fuel Program

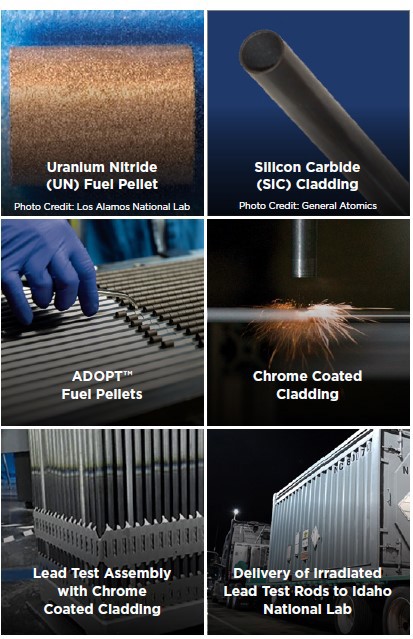

The EnCore program consists of two phases. The initial phase focuses on chromium coated cladding (fuel rods) loaded with ADOPT™ fuel pellets coupled with higher enrichment and higher burnup. The second phase focuses on the use of silicon carbide (SiC) cladding and uranium nitride (UN) fuel pellets.

Program Achievements

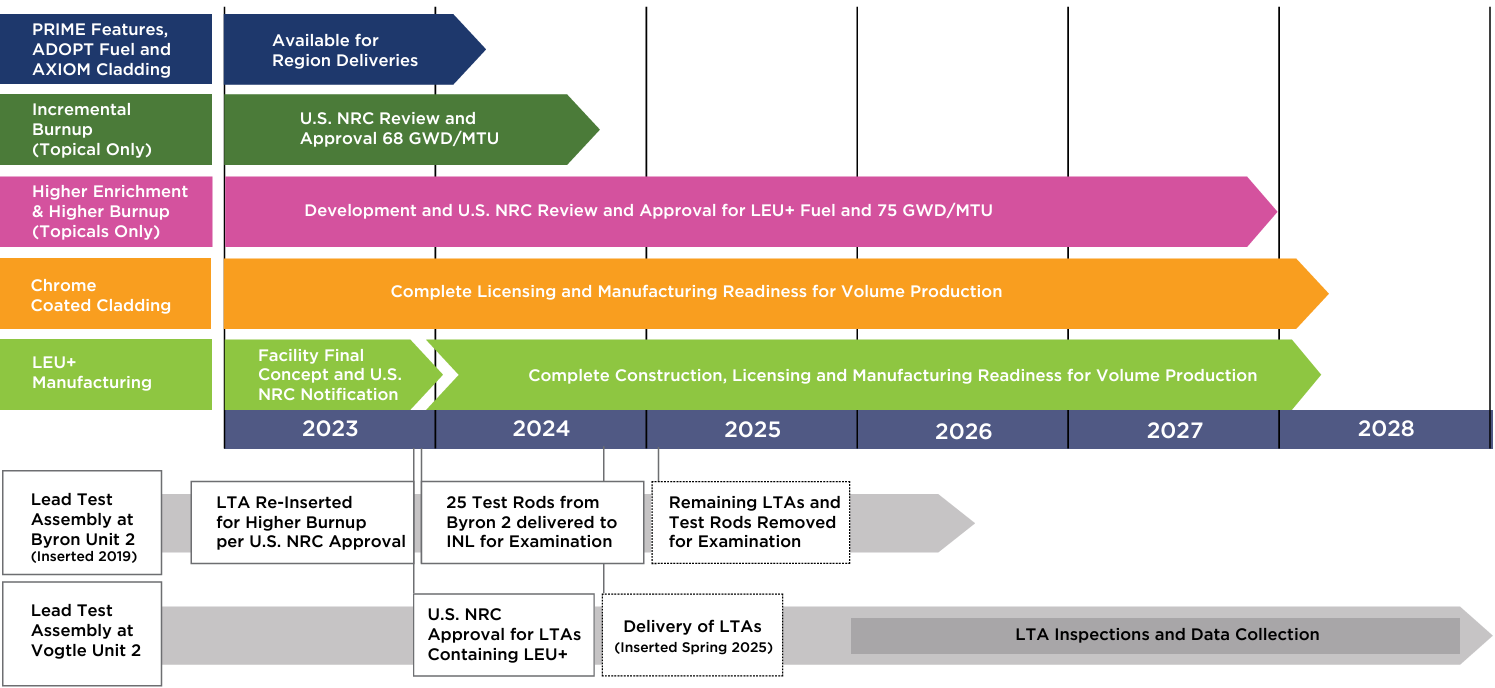

- Delivery of ATF Lead Test Assembly (LTA) to Byron 2 Nuclear Power Plant

- U.S. NRC Approval and Re-Insertion of LTA and Lead Test Rods at Byron 2 Nuclear Power Plant for “Higher Burnup”

- Delivery of Irradiated Lead Test Rods to Idaho National Labs (INL)

- U.S. NRC Approval of ADOPT™ Pellets

- U.S. NRC Approval of AXIOM® Cladding

- U.S. NRC Approval of Vogtle Unit 2 to Receive and Use LEU+ Fuel

- Submittal of Higher Enrichment Topical to U.S. NRC

- Commercial Contracts with Several Utilities for ADOPT Pellets

- Commercial Contracts with Several Utilities for AXIOM Cladding

- Columbia SC, USA Fuel Facility site Letter of Intent for LEU+ Submitted to U.S. NRC

Westinghouse ATF Products

Chrome Coated Cladding – Chromium coating on the outside of existing zirconium based fuel cladding increases safety and operational margins and may enable greater energy extraction.

AXIOM® Cladding – A unique zirconium-based alloy developed to enable nuclear fuel to run longer and provide more energy, while increasing safety margins.

ADOPT™ Fuel Pellets – The large grain size and density of Chromia and Alumina doped fuel pellets, enable increased energy density, improved stability at high temperatures and additional safety margins.

SiC Cladding and UN Pellets – SiC’s extremely high melting point and thermal conductivity has the potential to offer several significant safety and performance benefits.

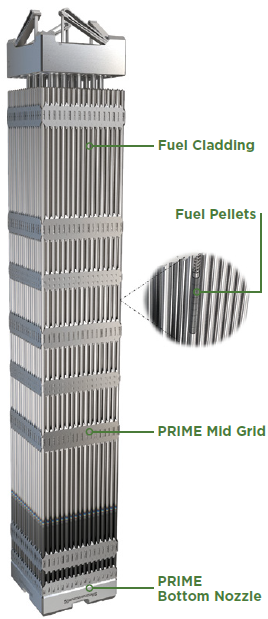

PRIME™ Fuel Features – This is a family of several unique fuel assembly features designed to improve fuel performance, enhance fuel cycle economics, and provide increase safety margins at higher burnup.

LEU+ and Higher Burnup – This includes the fabrication of higher enriched fuel and a suite of advanced engineering codes and tools that allow utilities to operate their reactors with Westinghouse ATF hardware technologies and deliver measurable benefits.

Program Schedule for Licensing, Testing, and Volume Protection