Background

Westinghouse has developed advanced fuel assembly features and supporting PWR core component products to improve fuel performance, enhance fuel cycle economics and support extended (24-month) cycle length operation. One such PWR core component is a Wet Annular Burnable Absorber (WABA) assembly, a discrete burnable absorber component used in some WNSSS reactor core fuel cycle loading strategies.

Description

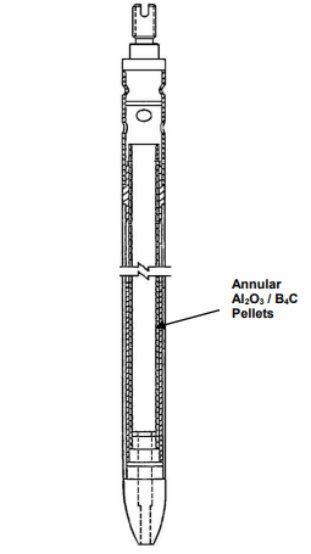

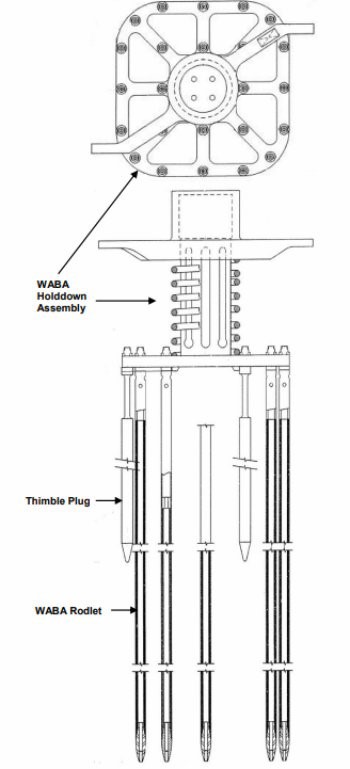

A WABA rodlet consists of annular pellets of alumina-boron carbide (Al2O3 / B4C) burnable absorber material contained within two concentric Zircaloy-4 tubes. These tubes form the inner and outer cladding for the annular burnable absorber rodlet that is plugged and seal-welded at the ends to encapsulate the annular stack of absorber material. The WABA rodlets and stainless-steel thimble plugs are grouped and attached at the top end of the rodlets to a hold-down assembly and retaining plate. An annular plenum is provided within each WABA rodlet to accommodate the helium gas released from the absorber material during boron depletion as a result of neutron irradiation.

A WABA assembly is inserted into the top of a fresh fuel assembly with the rodlets fitting into the guide thimble tubes. The reactor coolant flows inside the inner tube and outside the outer tube of the annular rod for cooling purposes.

From a neutronics standpoint, WABA assemblies provide significant reactivity hold-down capability to the host fuel assemblies early in cycle and then deplete throughout the cycle, resulting in low residual reactivity hold-down near the end of cycle. The reactor coolant in the inner tube improves thermalization of neutrons near the absorber material, and the reduced thickness of the annular pellets enables higher localized flux levels and more complete burnout of the absorber material during cycle operation.

Benefits

The benefits of deploying WABA assemblies in fuel cycles include:

- Improved control of fuel assembly and fuel rod peaking factors throughout cycles

- More negative moderator temperature coefficient and lower soluble boron concentration requirements near beginning of cycle

- Augmented reactivity hold-down of fresh fuel for potentially longer periods of time than can be achieved by other fuel rod burnable absorbers. This augmented reactivity hold-down can help facilitate extended (24-month) operating cycles.

- Removal of the WABA assemblies after the first cycle of operation eliminates any residual reactivity hold-down associated with these PWR core components, thus maximizing the carryover reactivity of the associated host fuel assemblies into the next operating cycle.

- Compared to other fuel reactivity hold-down products, use of WABA assemblies might facilitate either lower fuel enrichments for a given set of cycle lengths or greater cycle lengths for the same set of enrichments, depending on the desired fuel cycle energy requirements.

Experience

WABA assembly designs exist for all 14x14, 15x15 and 17x17 W-NSSS lattice configurations. The WABA assembly designs and their use in reactor operating cycles were fully licensed by the U.S. NRC in 1983 (WCAP-10021). Since 2000, more than 8,000 WABA assemblies containing over 120,000 WABA rodlets have been fabricated by Westinghouse and used in W-NSSS operating cycles with excellent performance history, including cycles that have also deployed Integral Fuel Burnable Absorber (IFBA) [ZrB2 coated fuel pellets] fuel rods. In some of these cases, the use of WABA facilitated the implementation of long (24-month) cycle operation.