Westinghouse is a world leader with a range of remediation experience with plant sites, facilities and uranium mines and mills, both privately and government owned.

The Westinghouse approach begins with a detailed action plan designed to resolve many fundamental issues. Westinghouse’s custom action plans integrate all necessary knowledge, including regulatory criteria, site characteristics, types of waste and public and policy management.

Westinghouse can perform a detailed inventory and radiological assessment to ensure compliance with waste acceptance criteria.

Westinghouse’s waste management experience combines conceptual design, engineering, technology development, detailed design, procurement, manufacturing and delivery, installation, testing, commissioning, training, documentation, licensing and operation of waste treatment systems for dry active wastes, liquids, sludge, concentrates, spent resins or other types of radioactive waste.

Westinghouse’s engineering solutions reduce disposal costs and provide a higher level of safety.

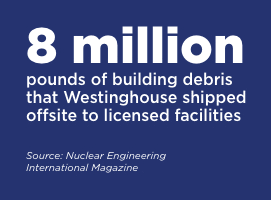

Westinghouse managed and performed the entire decommissioning effort at the Hematite Fuel Fabrication Facility, also known as Hematite Former Fuel Cycle Facility and the Westinghouse Electric Company Hematite Facility. The first privately owned and operated uranium fuel production plant in the United States, this facility produced nuclear fuel for military and peacetime purposes throughout the Cold War era of 1956 to 1974.