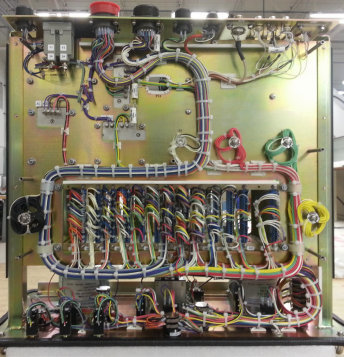

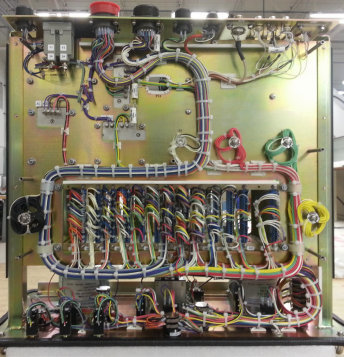

Eagle power supply assembly

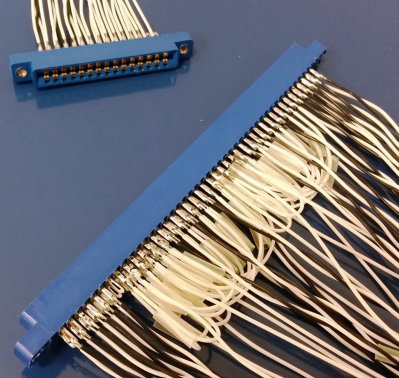

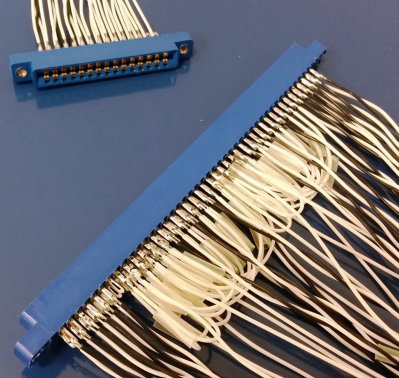

DRPI head cable

Background

At the Westinghouse Nuclear Parts Operations (NPO) Electro-Mechanical Assembly (EMA) and Instrumentation and Control (I&C) shop in New Stanton, Pennsylvania (USA), Electrical Operations provides electrical and I&C replacement parts and new systems for Westinghouse and Combustion Engineering designed operating plants, along with assembly and testing of prototype and production systems for new plant and upgrade projects. NPO technicians also provide field service groups with components, tooling, equipment and technician assistance during customer outages and plant upgrade services.

Description

NPO offers products manufactured and tested in the EMA and I&C shop for operating plant life extension and new plant systems including:

- 7300 and Eagle system components and cables

- Nuclear instrumentation system components

- Solid state protection system components

- Control element drive mechanism control system subgroup logic housing assembly

- Power switch refurbishments/replacements

- Rod control replacement cards and components

- AP1000® digital rod position indication (DRPI) cabinet system

- AP1000 special monitoring system cabinet system

- Analog rod position indication cables, control rod drive mechanism and DRPI head and field cables

- Nuclear steam supply system integrity monitoring system

Excore drawer assemblies

Benefits

We integrate Human Performance fundamentals and tools, Institute of Nuclear Power Operations principles, Lean Enterprise, and Six Sigma with the Westinghouse Quality Management System to support continuous improvement, our nuclear safety culture, and a safety conscious work environment.

The work processes NPO uses also provide opportunities for the improved efficiencies and innovation that our customers expect. We use SAP® enterprise resource planning software to manage production from the moment an order is entered until the final product is delivered to our customer. We manage material traceability, master bill of material/design management, shop floor control processes, and quality assurance through SAP for everything from first-of-a-kind builds to replacement components and systems.

The NPO Electrical Operations manufacturing schedule is level loaded but remains flexible to meet our customers’ requirements. We are prepared to supply our customers with high quality and timely, cost-effective replacement parts and also respond quickly to emergent needs.

The EMA and I&C shop can provide build-to print solutions for I&C, electrical, and electro-mechanical systems serving operating plants across the global nuclear industry. We are a part of the Westinghouse team dedicated to meeting customers’ needs for extended plant life, reduced operating costs and maximized up-time for operating plants.

Special processes and skills including soldering and wire wrapping

Westinghouse provides quality products that meet nuclear industry and IPC standards

Experience

We team product and design engineers with skilled technicians with nuclear industry experience, technical training, and certifications including:

- American National Standards Institute electrical certification

- IPC-A-610 Acceptability of Electronic Assemblies certification

- IPC/WHMA-A-620 Requirements and Acceptability for Cable and Wire Harness Assemblies certification

- IPC J-STD-001 Requirements for Soldered Electrical and Electronic Assemblies certification

- IPC 7711/7721 Rework of Electronic Assemblies/Repair and Modification of Printed Boards and Electronic Assemblies certification

- Build-to-print experience with replacement, prototype, and first-of-a-kind product

- Factory acceptance testing experience including functional and integration

AP1000 is a registered trademark of Westinghouse Electric Company LLC, its affiliates and/or its subsidiaries in the United States of America and may be registered in other countries throughout the world. All rights reserved. Unauthorized use is strictly prohibited.

SAP is a trademark or registered trademark of its respective owner. Other names may be trademarks of their respective owners.