Background

Optimized ZIRLO™ High-performance Fuel Cladding Material represents an evolutionary development of Westinghouse’s ZIRLO® High-performance Fuel Cladding Material.

Initially, pressurized water reactor fuel rods were made of 304 stainless steel tubing. Westinghouse developed Zircaloy-4 to improve neutron efficiency. Then, to improve the corrosion margin, the tin content was reduced further. Research and development resulted in the introduction of ZIRLO material to improve growth and creep while further enhancing corrosion resistance.

Westinghouse developed Optimized ZIRLO material to provide superior corrosion resistance, while maintaining excellent dimensional stability and predictable growth. Optimized ZIRLO helps utilities meet more demanding fuel duties, and achieve higher burnup and increased fuel temperatures.

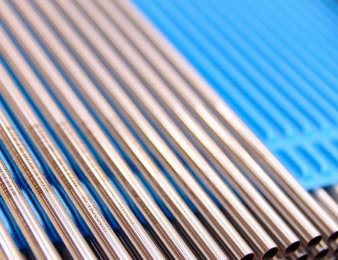

Description

Close-up of Optimized ZIRLO Tubes

Optimized ZIRLO material provides improved corrosion resistance by reducing the tin content of the fuel rod cladding. Because lithiated water increases corrosion at very low tin content, an optimum tin content point was selected for Optimized ZIRLO material to balance the improvement in general corrosion with good performance in aggressive coolant chemistry environments.

Optimized ZIRLO cladding is partially recrystallized to retain the superior creep properties of ZIRLO cladding. This is accomplished with a unique set of annealing parameters during cladding fabrication.

Optimized ZIRLO material is currently licensed by the U.S. Nuclear Regulatory Commission for use by utilities.

Benefits

Optimized ZIRLO Tube Assembly Ready for Inspection

Optimized ZIRLO material has many properties that are similar to ZIRLO material, but adds value through increased corrosion margin coupled with enhancements to attain flawless fuel performance. Its benefits include:

- A 40-percent reduction in corrosion relative to ZIRLO material

- Lower hydrogen pickup resulting from enhanced corrosion resistance, providing improved margins for accommodating the new regulator-mandated hydrogen-based ductility requirements for cladding safety analyses

- Proven corrosion performance in high boiling duty service with demonstrated performance at burnups up to 74 GWd/MTU

- Improved rod internal pressure margins

Comprehensive hot cell examinations have been performed on Optimized ZIRLO clad fuel rods to validate poolside corrosion and growth measurements, confirm the lower overall hydrogen inventory and measure the strength and ductility after operation. The evolution of the microstructure and its response to irradiation have been examined in detail by optical microscopy as well as scanning-electron and transmission-electron microscopy. Other evaluations performed include: profilometry, detailed visual exams, fission gas release, and rod internal pressure measurements.

Experience

In 2000, low-tin ZIRLO, stress-relief annealed cladding, the precursor to today’s Optimized ZIRLO, was inserted into a reactor in Spain. Also in 2000, Optimized ZIRLO rods were first used in lead test assemblies.

In the United States, the first reloads of Optimized ZIRLO rods were delivered in 2008 and the first full core was achieved in 2010.

As of year-end 2015, Optimized ZIRLO clad fuel has operated in over 41 plants. Full reloads of Optimized ZIRLO clad fuel are currently operating in 27 units worldwide. By the end of 2015, nine units will have full cores. Over 4900 assemblies have been delivered with Optimized ZIRLO representing over 1,178,000 fuel rods in operation or discharged.

Optimized ZIRLO and ZIRLO are trademarks or registered trademarks of Westinghouse Electric Company LLC, its affiliates and/or its subsidiaries in the United States and may be registered in other countries throughout the world. All rights reserved. Unauthorized use is strictly prohibited.