The Problem

Solving corrosion-related issues is a major challenge for the worldwide ageing fleet of nuclear power plants, looking for LTO (long-term operation).

While utilities can proceed to replacements for many pipes affected by corrosion, a replacement strategy is not always possible. Other maintenance solutions are required for inaccessible or embedded pipes. Moreover, for those pipes which cannot be replaced, internal inspection and corrosion removal become an even greater technical challenge if the pipe’s diameter is small and when the remote access to the zone of interest requires to travel through bended sections and elbows.

The Westinghouse Solution

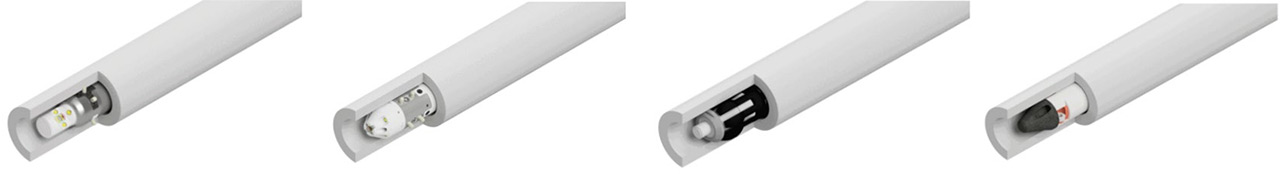

The Westinghouse small bore piping inspection and repair set of flexible tools includes:

- An ultrasonic testing (UT) wall thickness measurement tool.

- Axial and radial visual inspection tools.

- A machining tool to eliminate the corrosion indications from the pipe’s inner diameter.

- A push-pull system to insert and extract the four above-mentioned tools.

- Each tool is currently available with an external diameter of less than 19 mm.

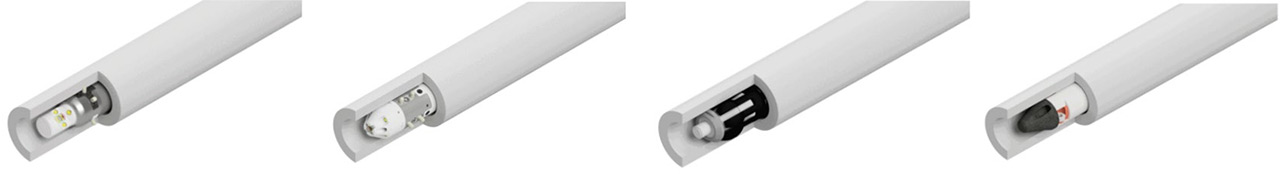

From left to right: Radial visual inspection tool, Axial visual inspection tool, Wall thickness UT inspection tool, Corrosion machining tool

Piping with singularities

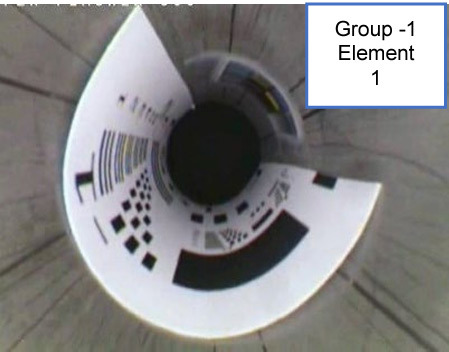

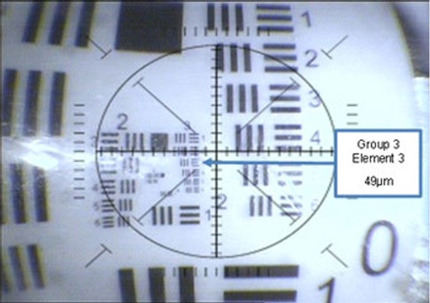

1951 USAF sight into the pipe

1951 USAF sight into the pipe

Result of the machining process

Description

-

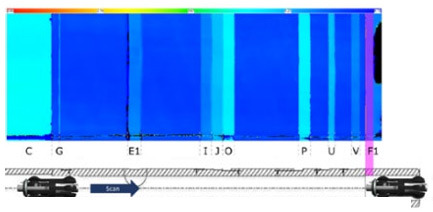

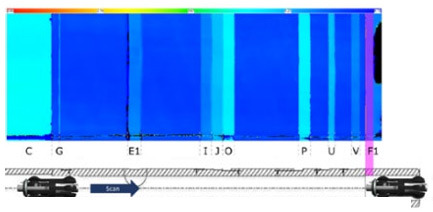

Wall thickness UT inspection tool

Used to measure the wall thickness and the internal profile of a small bore pipe.

- Measures thickness up to 11 mm at 360°

- Measurement accuracy: 0.1 mm

- Associated with an encoder, this tool allows to generate the scan of the pipe, as shown here:

-

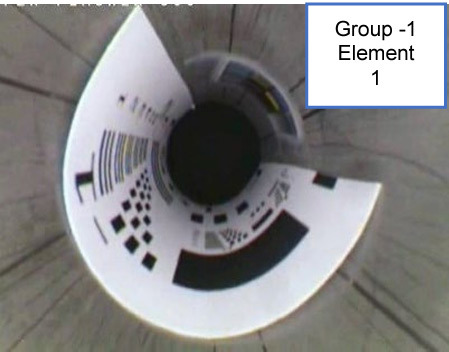

Axial visual inspection tool

Used to locate singularities with a minimum size of 1 mm and to clean the pipe after the machining operation with its cleaning nozzles.

-

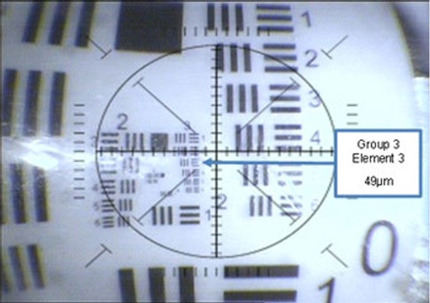

Radial visual inspection tool

Used to locate singularities with a minimum size of 49 μm.

- Camera focus: 4 mm to 190 mm

- Rotating camera

- Localizing singularities at 360°

-

Machining tool

Used to machine a pipe in order to eliminate singularities.

- Existing dimensions (customizable):

- length: 12 m

- diameter: 18.5 mm

- Flexible tool driven by a hydraulic fluid, which allows the expansion to different diameters of the machining modules.

- Machining modules allow the increase of the pipe

Benefits

- Westinghouse can perform an integrated service, including inspection of the as-found conditions, elimination of the corrosion indications and final inspection.

- The tools are remotely operated and the control stations can be installed at an ALARA area.

- The UT wall thickness measurement provides direct results, with no need for post-processing the results.

- The machining heads dimensions can be adjusted to different pipe diameters.

- The machined chips are evacuated and collected with the water delivered by the machining tool.

Westinghouse’s Experience

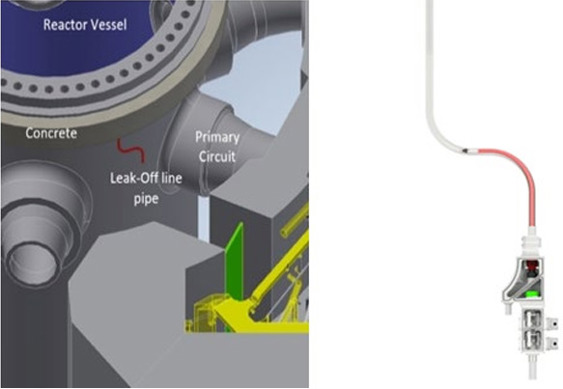

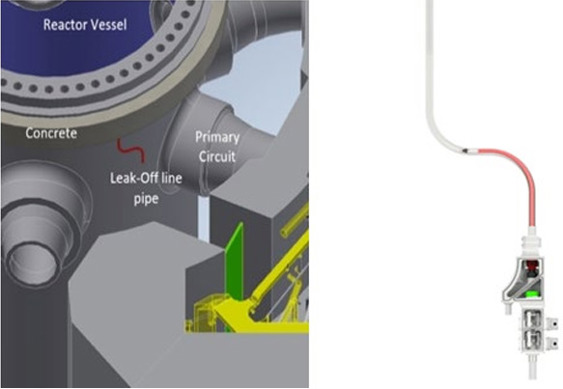

Reactor vessel and leak-off line environment (left) with clamping module and a tool into the pipe (right)

Each of these tools is qualified for implementation on Reactor vessel leak-off lines for the French PWR fleet.

Reactor vessel leak-off line visual inspections, triggered by reactor vessel head leak issues on several PWR units, have revealed indications for potential stress corrosion-induced damages in leak-off lines. Damages on the inside of the leak-off lines include corrosion pits, longitudinal and circumferential scratches, as well as oxide deposits. These damages being activated by temperature, their importance is increasing in the part of the leak-off line directly embedded in the reactor vessel flange.

The final section of the leak-off line is embedded in the reactor vessel flange and can therefore not be replaced. By eliminating the corrosion-induced damages, the process reduces risks of reactor vessel leak events, which have a significant outage critical path impact when they occur.