The AP1000® reactor is a two-loop pressurized water reactor (PWR) that uses a simplified, innovative, and effective approach to safety. With a gross power rating of 3,415 megawatts thermal (MWt) and a nominal net electrical output of 1,110-megawatt electric (MWe), the AP1000 reactor, with a 157-fuel-assembly core, is ideal for new baseload generation.

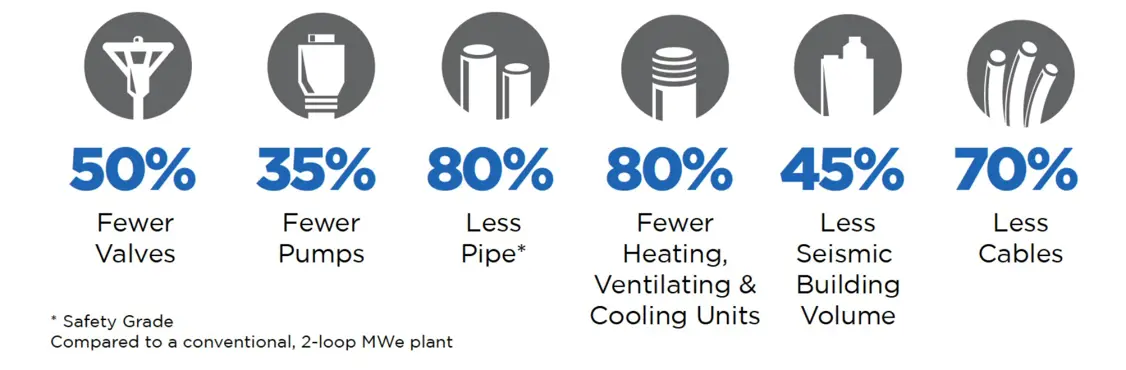

Simplification was a major design objective of the AP1000 reactor. Simplifications in overall safety systems, normal operating systems, the control room, construction techniques, and instrumentation and control systems provide a technology that is easier and less expensive to build, operate, and maintain. These simplifications yield fewer components, cable, and seismic building volume, all of which contribute to considerable savings in capital investment, and lower operation and maintenance costs. At the same time, the safety margins for the AP1000® reactor have been increased dramatically over currently operating reactors.

The AP1000 PWR is comprised of components that incorporate many design improvements distilled from 50 years of successful operating nuclear power plant experience. The reactor vessel and internals, steam generator, fuel and pressurizer designs are improved versions of those found in currently operating Westinghouse-designed PWRs. The reactor coolant pumps are canned-motor pumps, the type used in many other industrial applications where reliability and long life are paramount requirements.