Technologies

Westinghouse offers an extensive line of products and technologies that complement the services we provide with innovative solutions including Remote & Automated Monitoring, Robotic Cleaners, Modular Scaffold Programs, Buried Pipe Inspection Services and Portable HEPA Ventilation Systems.

Power generation and government facilities rely on our technology-based solutions to increase safety, provide cost savings, and reduce radiological exposure and critical path time.

Remote & Automated Monitoring

Westinghouse’s Automated Monitoring Systems encompass fully integrated telemetry, video and communications designed for remote, centralized and automated monitoring of radiological and project activities.

Our team can custom design and fabricate solutions to meet your facility’s requirements for security and communication. These solutions can also assist you in reducing dose, while increasing radiological safety margin.

Solutions include:

- Video Management Software and Hardware

- Security Software and Systems

- Communications Software and Systems

- Telemetry Monitoring Software

- Dose & Activity Software

- Wireless Heat Stress Monitors

- Radiation Tolerant Cameras

VIEW DETAILS

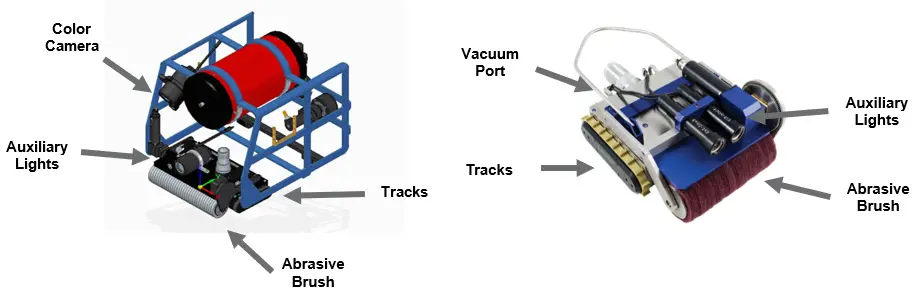

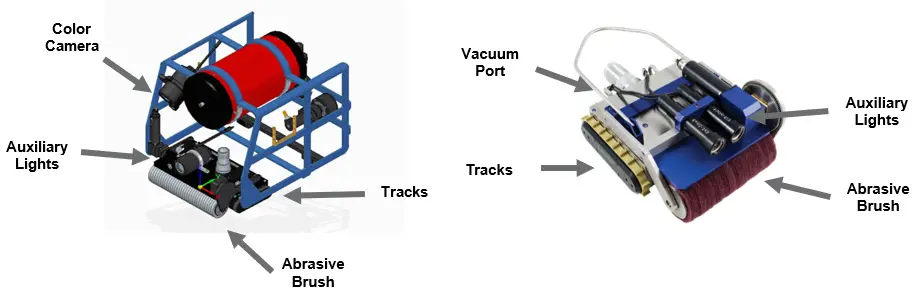

Remote Robotic Tank Cleaning

Westinghouse provides remote robotic cavity cleaning services that reduce outage costs, lessen personnel time and decrease the chance of fuel system issues.

Our innovative cavity cleaning services reduce contamination levels by 50 to 80 percent, thereby reducing personnel exposure and decontamination time post-cavity drain down. By using automated solutions, risk to personnel and human error risks are minimized, as is foreign material intrusion.

Designed to clean in parallel with refueling activities, customers benefit from reduced source term and critical path schedule. The system cleans open surfaces as well as constrained and recessed areas utilizing robotic crawlers and mechanical agitation.

This product suite services all major areas of the cavity, including Upper and Lower Cavity Floors, Upper and Lower Cavity Walls, the Fuel Transfer Canal, The Fuel Travel Path, the Reactor Flange, and O-Ring Groove.

VIEW DETAILS

Spent Fuel Pool Under Rack Services

Our remotely operated Spent Fuel Pool Under Rack services mitigate the risks of accumulated foreign material under the spent fuel storage racks by characterizing and retrieving foreign objects before they can create challenges to plant safety. Foreign material can be particulate/sludge-like or foreign objects that can affect pool clarity and visibility as well as increasing the potential for debris-induced fuel failure when objects are drawn up and into fuel by piston action of the fuel assembly.

Foreign objects are characterized and retrieved using a site-provided vacuum filtration system with the vacuum crawler or by using the remotely operated crawler’s mechanical gripper. Westinghouse’s system consists of a Control Console that controls the Under Rack Crawler as well as the Submersible Pan, Tilt and Zoom Camera System with lighting.

Our approach is proven to reduce personnel radiation exposure and risk, decrease human performance errors and the number of personnel needed, and lower the risk of debris-induced fuel failure.

VIEW DETAILS

Scaffold Programs

Westinghouse’s scaffold management program utilizes Excel Modular Scaffold, recognized as the most safe and efficient scaffold material in the industry and recommended by industry regulators such as the Electric Power Research Institute (EPRI). Westinghouse exclusively offers two innovative, patented scaffold components developed by Deltak Manufacturing, Inc. for Excel that deliver savings through:

- Reduced labor time and cost

- Reduced material handling and radiation exposure

- Reduced radiation exposure consistent with ALARA objectives

- Decreased critical path and inspection time

- Increased safety and efficiency

LEARN MORE

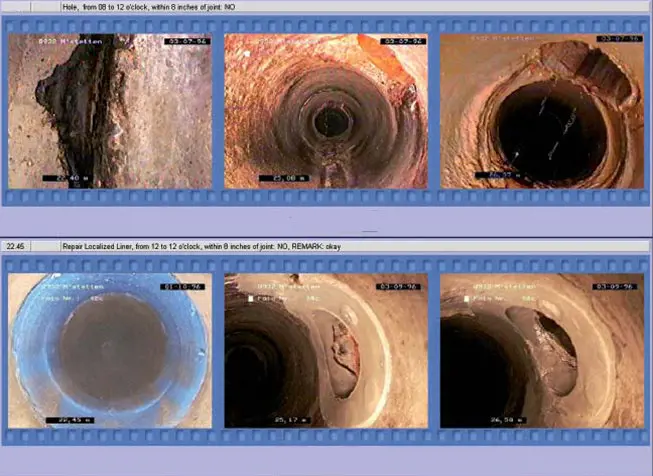

Buried Pipe & Storm Drain Inspection Services

Westinghouse offers turnkey NEI 09-14 Buried Piping Initiative Program (BPIP) services including assessment, inspection, mitigation and rehabilitation. Our proprietary Sub-Surface & Embedded Pipe Inspection System (SEPIS) permits visual inspection and radiation surveys concurrently with radiation survey results recorded directly on the visual inspection record for piping systems from 2-24 inches in diameter in a single pass.

Utilizing mobile robotic crawlers and haloptic technology to see and record deep into confined spaces, our services offer a site-specific, sub-surface and embedded internal piping inspection solution to our clients that saves time and money.

Portable HEPA Ventilation Systems & Accessories

During activities that can create airborne contamination, Westinghouse provides nuclear-grade HEPA filtered systems to maintain high air quality with a variety of portable, lightweight and compact models. With full design capabilities to 10,000 cfm from compact units to high-velocity workhorses for high static loads, and a range of parts and accessories to get the job done right, Westinghouse offers rugged solutions for ventilation and vacuum to safely trap and contain nuclear material.

Solutions include:

- Nuclear Grade HEPA Filtration Systems & Accessories

- Accessories like Flexible Hoses and Muzzlers

- HEPA Vacuum Units

- Charcoal Filtration Trays

For more information on our technologies, please contact us by clicking the button below.

CONTACT US