In addition to the skill and talent of the company’s staff in this area, Westinghouse offers:

Read this feature about how Westinghouse leverages its knowledge, based on more than 30 years of experience in decommissioning and waste processing, to assist utilities in the last stage of the life cycle of a nuclear power plant.

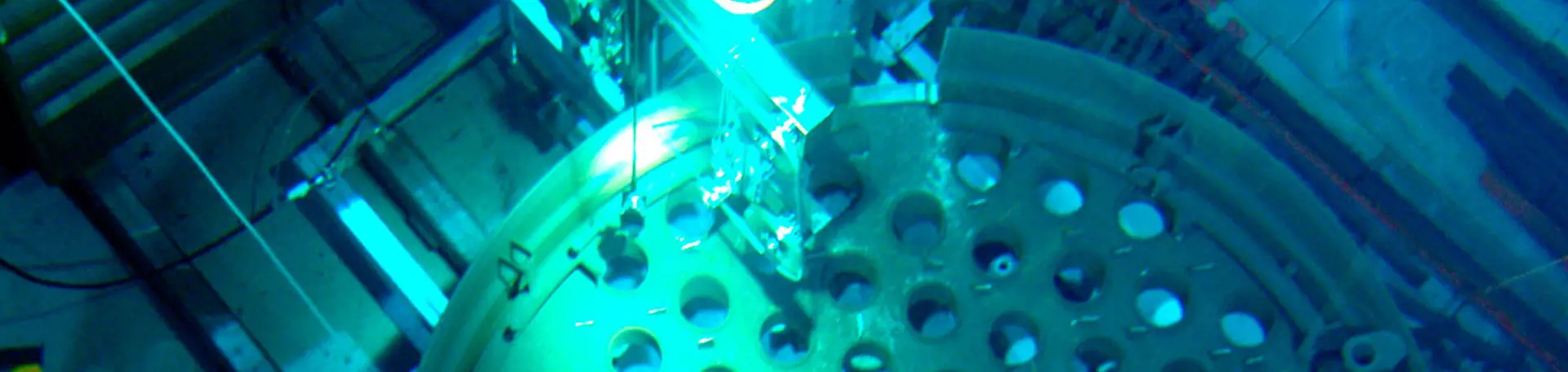

Read about how Westinghouse successfully completed, safely and ahead of schedule, the first reactor internals segmentation project to be performed on a commercial unit in Sweden at unit 2 of the Barsebäck nuclear power plant.

Westinghouse is working on the first VVER-440 units to be dismantled and the company’s largest dismantling project to date at Slovakia’s Bohunice V1 plant.

BWR Reactor Pressure Vessel Internals Segmentation and Packaging