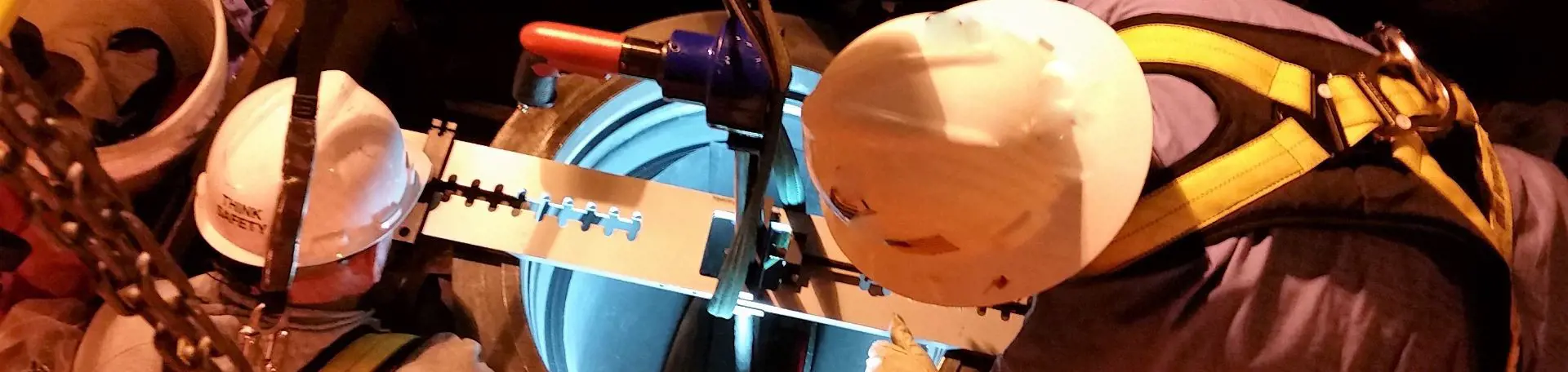

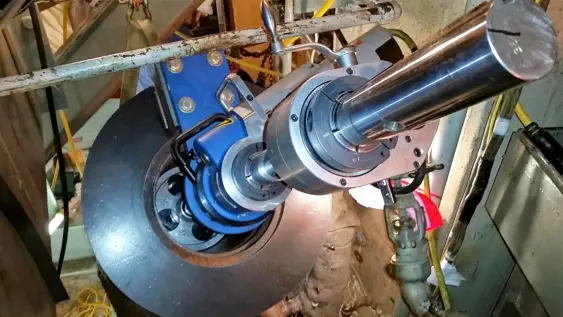

We leverage our industry-recognized training programs, integrated project management approach and our first-time quality process to ensure that our customers’ most complex valve projects are completed on time and on schedule.

Providing over 4 million hours of outage-related valve services, supporting over a thousand valve and actuator service projects, we use an integrated planning and project management system to safely execute any valve project on schedule and on budget. Our process includes in-depth pre-planning, comprehensive project reviews, risk assessments and contingency development.

Our workforce is supported by an INPO-modeled, performance based EPRI AP3 compliant technical training and qualification program that has been accepted as equivalent to several of our customers’ utility training programs. This equivalency-based approach improves quality while reducing cost and is aimed at providing customers the highest level of service.

For more information about how our valve solutions can benefit your next project, contact:

Jeff Bryant, Sr. Director Valves & Electrical (U.S.)

jeff.bryant@westinghouse.com

Christina Clancey, Customer Solutions Manager (Spain)

christina.clancey@westinghouse.com